Oct . 08, 2024 17:04 Back to list

Efficient Solutions for Pumping High Density Slurry in Industrial Applications

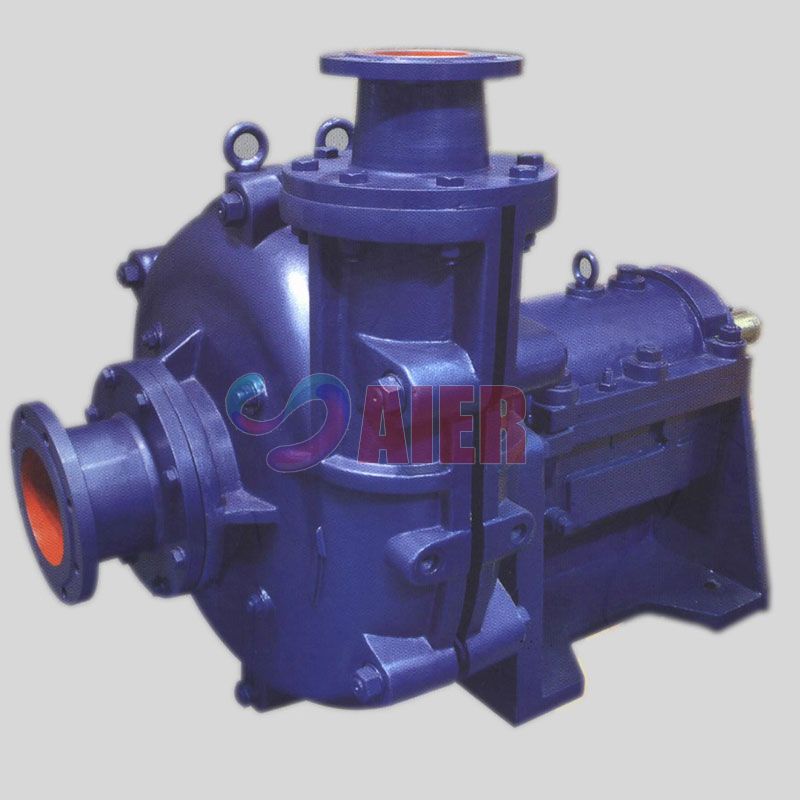

High Density Slurry Pumps An Overview

High density slurry pumps are essential equipment in various industries, particularly in mining, mineral processing, and construction. These pumps are specifically designed to handle slurries, which are mixtures of solids and liquids, often requiring the movement of thick, abrasive materials. The ability to effectively transport high density slurries is crucial for maintaining operational efficiency and productivity in processes such as ore extraction, tailings disposal, and dredging.

One of the primary challenges in pumping slurries is managing the viscosity and density of the material. High density slurries, containing a significant proportion of solid particles, can be particularly challenging due to their abrasive nature and the potential for settling. High density slurry pumps are engineered with robust features to tackle these challenges. They typically incorporate heavy-duty materials, such as cast iron or high-chrome alloys, to withstand wear and corrosion caused by the abrasive solids present in the slurry.

The design of high density slurry pumps often includes a wide inlet and specialized impeller geometry, which facilitates the efficient flow of thick mixtures. Additionally, many models are equipped with features that enable them to manage both slurry suspension and transfer effectively, reducing the risk of blockages and ensuring a continuous flow. Furthermore, variables such as pump speed, impeller size, and wear liner configurations can be adjusted to optimize performance based on the specific characteristics of the slurry.

high density slurry pump

Energy efficiency is another critical consideration in the design and operation of high density slurry pumps. With increasing energy costs and environmental concerns, manufacturers are focused on creating pumps that minimize energy consumption while maximizing output. This not only reduces operational costs but also improves the overall sustainability of industrial processes.

Regular maintenance is essential to keep high density slurry pumps functioning optimally. Routine inspections, seal replacements, and impeller refurbishments can significantly extend the life of the pump, ensuring it remains productive even under challenging conditions.

In summary, high density slurry pumps play a vital role in facilitating the movement of challenging materials across various industries. Their robust design, combined with continuous advancements in technology, ensures that they meet the demands of modern applications, delivering efficiency, reliability, and sustainability in the management of high density slurries. As industries evolve, the importance of sophisticated pumping solutions will only continue to grow, driving innovation in this essential equipment sector.

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025