Sep . 03, 2024 20:34 Back to list

high quality centrifugal slurry pump parts manufacturers

High-Quality Centrifugal Slurry Pump Parts Manufacturers

Centrifugal slurry pumps are pivotal in various industries, such as mining, metallurgy, and chemical processing. These pumps are engineered to transport abrasive and viscous materials, making them essential for operations involving heavy slurries. The efficiency and longevity of these pumps significantly depend on the quality of their components. Therefore, partnering with high-quality centrifugal slurry pump parts manufacturers is crucial for maintaining optimal performance and reducing operational costs.

When evaluating manufacturers of slurry pump parts, several factors should be considered, including material quality, manufacturing processes, and the experience of the supplier. High-quality components are paramount as they directly influence the durability and reliability of the pump. Reputable manufacturers typically use durable materials, such as high-chrome alloy or rubber, to withstand the harsh conditions that come with pumping slurry. These materials are designed to resist wear and corrosion, ensuring that the pump operates smoothly over extended periods.

Another critical aspect is the manufacturing processes employed by these manufacturers. Advanced technologies, such as precision casting, CNC machining, and heat treatment, play a significant role in producing high-quality pump parts. Manufacturers who invest in state-of-the-art equipment and technologies can provide components with tight tolerances and enhanced structural integrity. This meticulous attention to detail ensures that each component fits perfectly and functions seamlessly within the pump assembly, further reducing the risk of mechanical failure.

high quality centrifugal slurry pump parts manufacturers

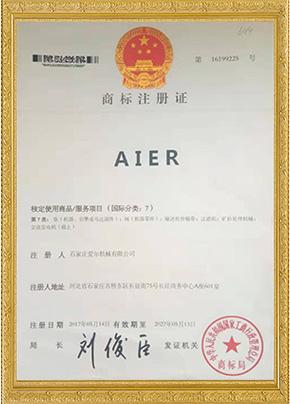

Additionally, the experience and reputation of the manufacturer should not be overlooked. Established manufacturers often have a wealth of knowledge and expertise that can be invaluable in choosing the right parts for specific applications. They are more likely to understand the nuances of different industries and can provide tailored solutions that meet unique operational demands. Furthermore, reputable manufacturers are usually committed to quality assurance and may have certifications that validate their products, such as ISO certifications.

Collaboration with high-quality manufacturers also opens the door to customized solutions. Many reliable companies can design and produce custom slurry pump parts tailored to specific requirements. This capability is particularly advantageous for industries with unique or challenging applications, where standard parts may not suffice. Custom solutions can lead to improved efficiency and performance, ultimately enhancing the overall productivity of the operation.

Moreover, a strong partnership with a reputable manufacturer can provide ongoing support and maintenance services. These manufacturers often offer technical support, training, and readily available spare parts. This level of service can significantly reduce downtime and ensure that maintenance is performed correctly, prolonging the life of the equipment.

In conclusion, selecting high-quality centrifugal slurry pump parts manufacturers is imperative for industries that rely on these pumps. By focusing on material quality, advanced manufacturing processes, and the manufacturers' experience, organizations can ensure they are investing in components that enhance pump performance and reliability. Ultimately, a solid partnership with a reputable manufacturer can lead to increased productivity, reduced operational costs, and sustained long-term success in the demanding field of slurry transport.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025