Jun . 24, 2024 04:30 Back to list

High-Quality Ash Slurry Pump for Submersible Use

Enhancing Efficiency with High-Quality Ash Slurry Submersible Pumps

In the realm of industrial fluid handling, the importance of reliable and efficient pumping systems cannot be overstated. A shining example of such innovation is the high-quality ash slurry submersible pump, a piece of equipment designed to move viscous mixtures like ash slurries with minimal effort and maximum efficiency.

Ash slurry, a mixture of water and pulverized fuel ash or fly ash, is commonly produced in power plants and industrial processes that burn coal or other fossil fuels. The disposal and transportation of this byproduct are critical environmental and economic considerations. This is where the submersible pump comes into play, offering an effective solution for moving large volumes of ash slurry from one location to another.

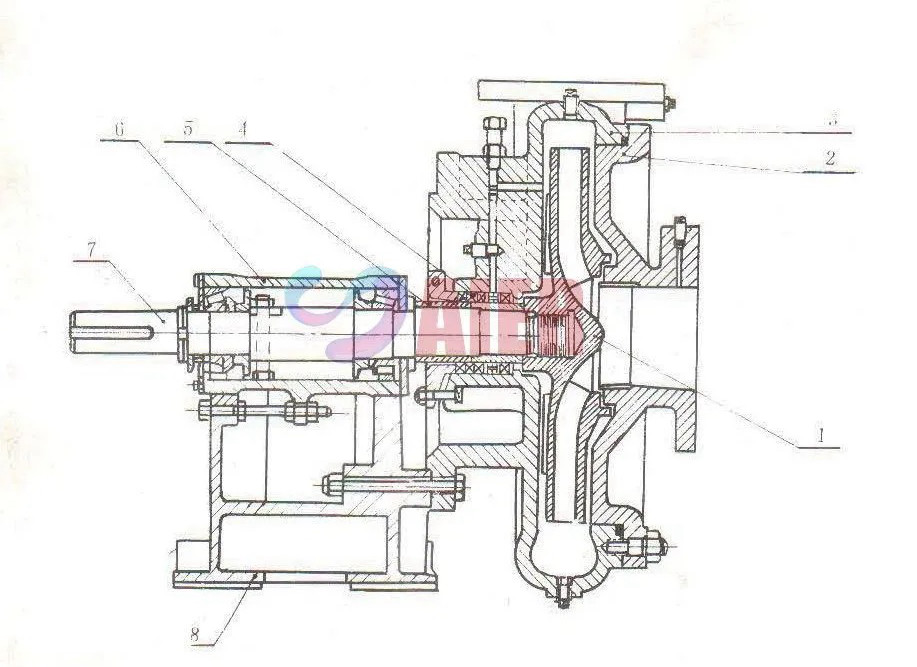

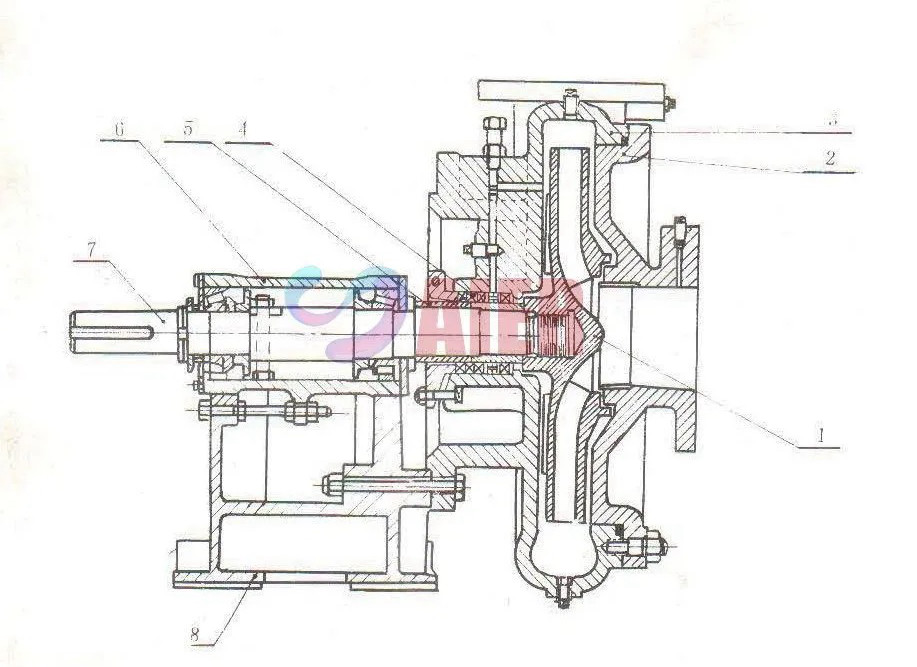

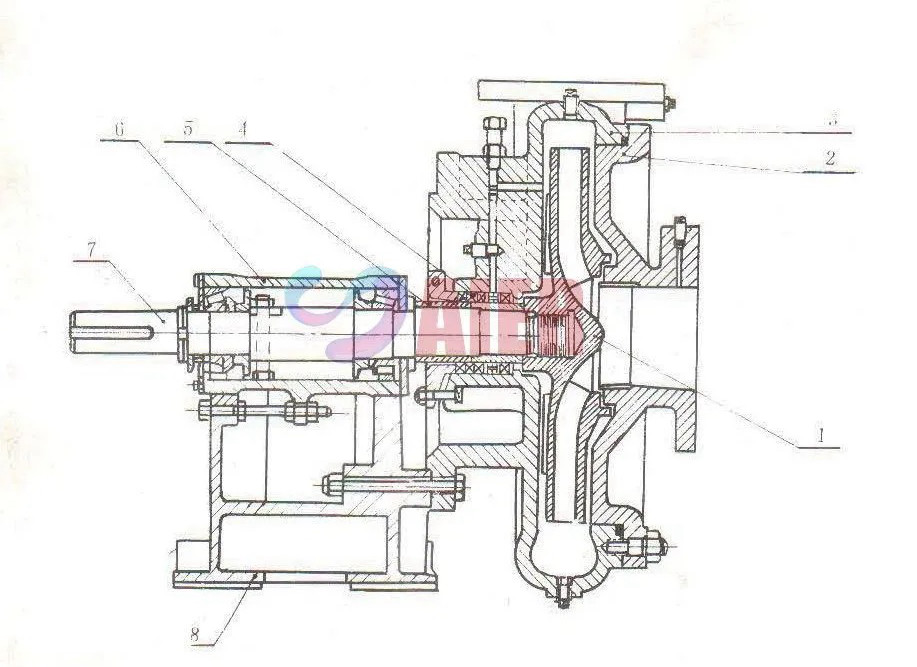

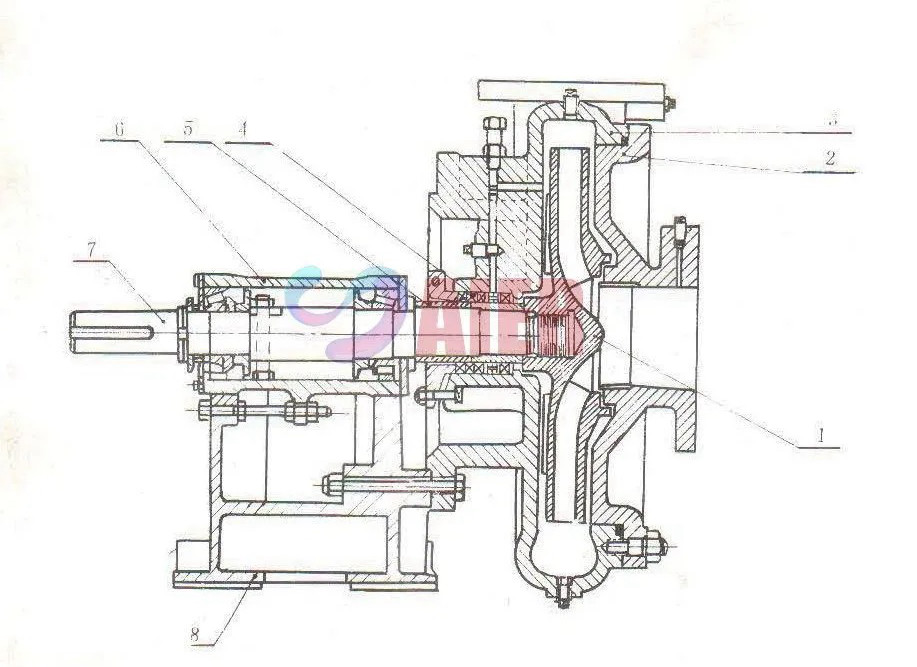

High-quality ash slurry submersible pumps are engineered to handle the abrasive nature of ash particles suspended in water. They feature wear-resistant materials, such as hardened alloys or ceramic components, which significantly extend their service life. These pumps also boast advanced sealing technologies to prevent leaks, ensuring that the pumped media does not contaminate the surrounding environment.

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material high quality ash slurry submersible pump. This not only saves space but also reduces energy consumption since the pump operates at the optimal depth for the slurry's density and viscosity.

One of the key benefits of using a high-quality ash slurry submersible pump is its ability to maintain consistent flow rates, even as the slurry's consistency changes. Advanced impeller designs create a smooth flow path, reducing clogging and improving overall system reliability. Additionally, many models come equipped with monitoring devices that can track performance metrics, alert operators to potential issues before they become major problems, and ensure that maintenance is performed proactively rather than reactively.

In conclusion, high-quality ash slurry submersible pumps represent a significant step forward in the management of industrial waste streams. Their robust construction, energy-efficient operation, and advanced monitoring capabilities make them an indispensable asset for any operation dealing with large quantities of ash slurry. By investing in such pumps, industries can optimize their processes, minimize downtime, and contribute to sustainable practices that benefit both the environment and the bottom line.

high quality ash slurry submersible pump. This not only saves space but also reduces energy consumption since the pump operates at the optimal depth for the slurry's density and viscosity.

One of the key benefits of using a high-quality ash slurry submersible pump is its ability to maintain consistent flow rates, even as the slurry's consistency changes. Advanced impeller designs create a smooth flow path, reducing clogging and improving overall system reliability. Additionally, many models come equipped with monitoring devices that can track performance metrics, alert operators to potential issues before they become major problems, and ensure that maintenance is performed proactively rather than reactively.

In conclusion, high-quality ash slurry submersible pumps represent a significant step forward in the management of industrial waste streams. Their robust construction, energy-efficient operation, and advanced monitoring capabilities make them an indispensable asset for any operation dealing with large quantities of ash slurry. By investing in such pumps, industries can optimize their processes, minimize downtime, and contribute to sustainable practices that benefit both the environment and the bottom line.

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material

The design of these pumps typically includes a submersible motor that allows the entire unit to be placed directly into the slurry, eliminating the need for additional machinery to lift the material high quality ash slurry submersible pump. This not only saves space but also reduces energy consumption since the pump operates at the optimal depth for the slurry's density and viscosity.

One of the key benefits of using a high-quality ash slurry submersible pump is its ability to maintain consistent flow rates, even as the slurry's consistency changes. Advanced impeller designs create a smooth flow path, reducing clogging and improving overall system reliability. Additionally, many models come equipped with monitoring devices that can track performance metrics, alert operators to potential issues before they become major problems, and ensure that maintenance is performed proactively rather than reactively.

In conclusion, high-quality ash slurry submersible pumps represent a significant step forward in the management of industrial waste streams. Their robust construction, energy-efficient operation, and advanced monitoring capabilities make them an indispensable asset for any operation dealing with large quantities of ash slurry. By investing in such pumps, industries can optimize their processes, minimize downtime, and contribute to sustainable practices that benefit both the environment and the bottom line.

high quality ash slurry submersible pump. This not only saves space but also reduces energy consumption since the pump operates at the optimal depth for the slurry's density and viscosity.

One of the key benefits of using a high-quality ash slurry submersible pump is its ability to maintain consistent flow rates, even as the slurry's consistency changes. Advanced impeller designs create a smooth flow path, reducing clogging and improving overall system reliability. Additionally, many models come equipped with monitoring devices that can track performance metrics, alert operators to potential issues before they become major problems, and ensure that maintenance is performed proactively rather than reactively.

In conclusion, high-quality ash slurry submersible pumps represent a significant step forward in the management of industrial waste streams. Their robust construction, energy-efficient operation, and advanced monitoring capabilities make them an indispensable asset for any operation dealing with large quantities of ash slurry. By investing in such pumps, industries can optimize their processes, minimize downtime, and contribute to sustainable practices that benefit both the environment and the bottom line. Latest news

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025