Nov . 07, 2024 06:38 Back to list

Gold Dredging Pump Components Manufacturer Offering High-Quality Parts for Efficient Operations

The Importance of Gold Dredge Pump Parts A Focus on Factory Production

Gold dredging has emerged as a significant method for extracting precious minerals from riverbeds and seabeds. Among the various components that make up a gold dredging operation, the pump plays a crucial role in ensuring efficiency and effectiveness. The functionality of the gold dredge largely hinges on the reliability of its pump system, making the quality of gold dredge pump parts paramount. In this article, we will delve into the importance of these components and the processes involved in their production at a dedicated factory.

Understanding Gold Dredge Pumps

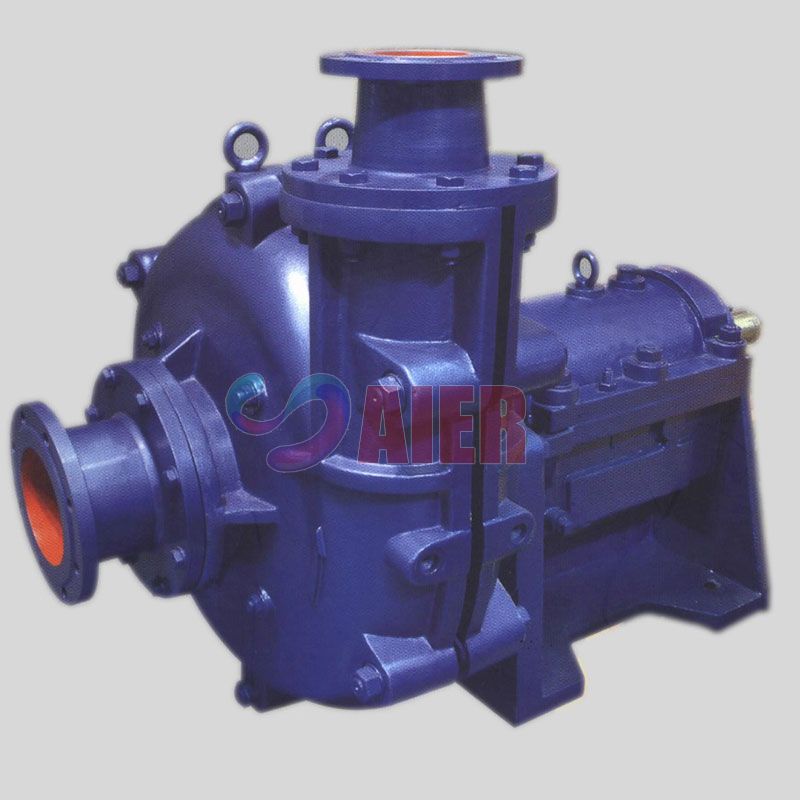

Gold dredge pumps are specialized equipment designed to handle the transportation of sediments rich in gold from underwater to the surface. These pumps are uniquely engineered to handle both water and solid materials without clogging or losing efficiency. Essential parts of a gold dredge pump include impellers, volutes, bearings, and seals, each of which plays a vital role in the pump's overall performance.

When a pump is operational, its impeller spins at high velocity, generating a centrifugal force that lifts water and sediment simultaneously. The volute then directs this mixture into the outlet, where it can be further processed to extract gold. Each part must function harmoniously with the others, which is why the quality of manufacturing is crucial.

The Manufacturing Process of Pump Parts

The manufacturing of gold dredge pump parts typically takes place in specialized factories equipped with advanced technology and machinery. The process begins with sourcing high-grade materials that can withstand the harsh conditions often encountered in dredging environments. Metal alloys that resist corrosion and wear are particularly important, given that dredging often involves abrasive materials.

Once the raw materials are procured, they undergo a series of processes, including casting, machining, and assembly.

gold dredge pump parts factory

1. Casting This is where raw materials are melted and poured into molds to form the basic shapes of pump parts. It requires precision to ensure that there are no defects, as even minor imperfections can affect the pump's performance significantly.

2. Machining After casting, the parts are precisely machined to meet the exact specifications required for optimal operation. This often involves techniques like milling, turning, and grinding. Highly skilled technicians oversee this stage to ensure that each part meets the rigorous quality standards expected in the industry.

3. Assembly The final stage involves the assembly of individual parts into a complete pump unit. During assembly, great attention is paid to ensure that all components fit perfectly, as this directly impacts overall performance and longevity.

4. Testing After assembly, the complete pumps undergo extensive testing. This includes pressure tests, performance evaluations, and operational endurance tests to guarantee that the pump will perform reliably in the field.

The Role of Quality Control

Quality control is a critical aspect of the manufacturing process in a gold dredge pump parts factory. Every component must undergo scrutiny to ensure durability and functionality. Factories often employ advanced testing equipment and methodologies like non-destructive testing (NDT) to identify any flaws in the materials or assembly. This dedication to quality ensures that the end products not only meet customer expectations but also perform efficiently in demanding environments.

Conclusion

In conclusion, the importance of high-quality gold dredge pump parts cannot be overstated. They are essential for the effective operation of gold dredging equipment, and their reliable performance contributes directly to successful gold extraction. Factories specializing in the production of these parts play a crucial role in the mining industry, utilizing advanced manufacturing techniques and stringent quality control measures to ensure excellence. As the demand for gold continues to rise, so too does the need for efficient and durable dredging equipment, making the role of pump parts factories more critical than ever in supporting this vital sector of the economy. Through a commitment to quality and innovation, these factories pave the way for advancements in gold dredging technology, promising a prosperous future in precious metal extraction.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025