Nov . 06, 2024 10:22 Back to list

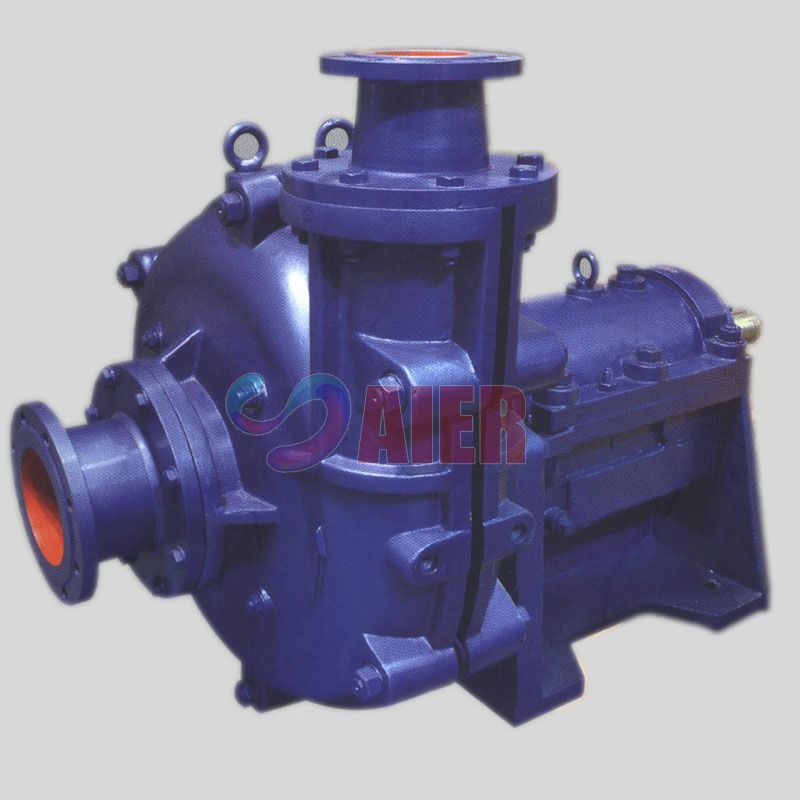

froth slurry pump manufacturer

The Role of Froth Slurry Pump Manufacturers in Mining and Mineral Processing

Froth slurry pumps play a crucial role in the mining and mineral processing industries. These specialized pumps are designed to handle challenging materials often found in mining operations, such as thick slurries composed of water, minerals, and various solid particles. The efficiency and reliability of these pumps are vital for the operational success and productivity of mining projects. Consequently, froth slurry pump manufacturers play a key role in this sector by developing advanced pumping solutions.

Froth slurry pumps are engineered to transport mixtures that typically exhibit a frothy consistency, which can arise from processes such as flotation. These pumps can handle abrasive materials and are designed to maintain high throughput rates while managing varying densities and viscosities of the slurry. The unique requirements of transporting slurry with a frothy nature necessitate specific design features, such as increased wear resistance and the ability to handle both abrasive and corrosive materials.

One of the significant challenges in selecting a suitable froth slurry pump is ensuring it can efficiently convey the slurry with minimal degradation. Froth slurry pump manufacturers invest in innovative technologies and materials to enhance pump performance and longevity. Many manufacturers utilize advanced computational fluid dynamics (CFD) modeling to optimize pump designs, ensuring the pumps can handle the dynamics of froth slurries effectively.

froth slurry pump manufacturer

Moreover, the customization of pumps to meet particular operational requirements is another crucial service provided by froth slurry pump manufacturers. Mining companies may face unique challenges, including varying slurry compositions, different flow rates, and specific site conditions. Manufacturers often collaborate closely with their clients to develop tailored solutions that maximize efficiency and reduce operational costs. This spirit of partnership is essential for ensuring that the pumping systems can seamlessly integrate into the established processes of different mining operations.

As environmental sustainability becomes increasingly critical within the mining sector, modern froth slurry pump manufacturers are also focusing on energy efficiency and minimizing waste. Innovations like variable speed drives and automated control systems are becoming more common, allowing for precise adjustments to pump performance based on real-time conditions in the slurry line. These advancements help reduce energy consumption and improve the overall sustainability of mining operations.

In conclusion, froth slurry pump manufacturers hold a vital position in the mining and mineral processing industries. Their commitment to innovation, customization, and sustainability not only enhances the efficiency of mining operations but also supports the industry's efforts toward environmentally responsible practices. As the demand for minerals continues to grow, the importance of reliable and effective pumping solutions will only increase, making the role of these manufacturers more significant than ever.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025