Jan . 26, 2025 01:06 Back to list

OEM Castings

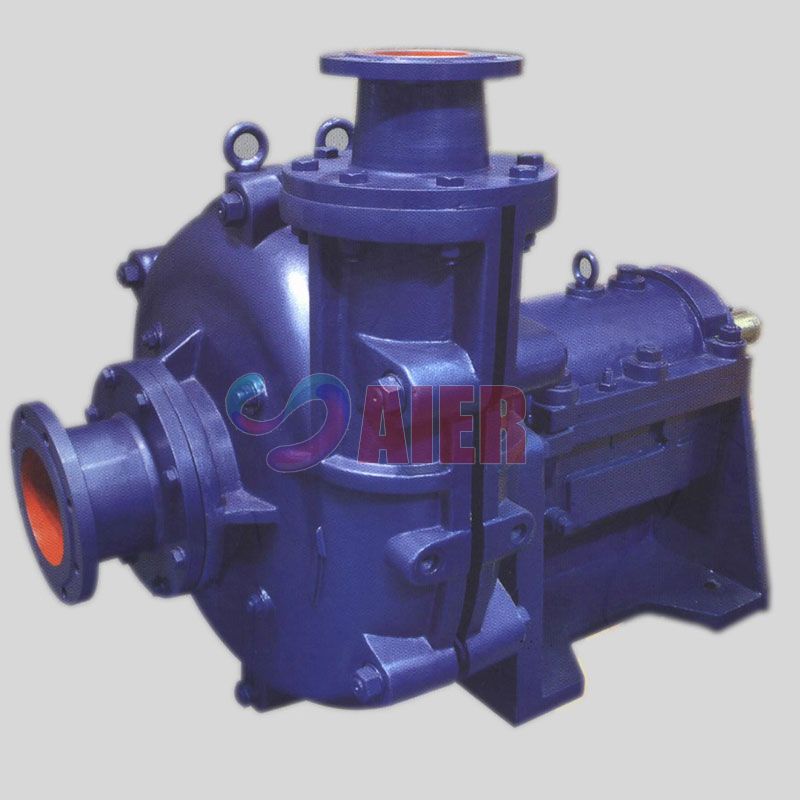

When it comes to industrial applications involving the transportation of abrasive and high-density slurries, froth centrifugal slurry pumps offer a highly efficient solution. These specialized pumps, designed to handle frothy slurries, such as flotation concentrates, play a crucial role in industries such as mining and mineral processing. To fully grasp the advantages and applications of froth centrifugal slurry pumps, one must consider factors like design, efficiency, and compatibility with various industrial processes.

Industrial experts have recognized the adaptability of froth centrifugal slurry pumps in diverse applications beyond mining and mineral processing. Industries such as oil sands, chemical processing, and power generation have embraced these pumps due to their ability to efficiently handle frothy mixtures. In oil sands operations, for instance, these pumps enable the transportation of bituminous froth, a challenging task for conventional pump systems, thus optimizing the extraction and processing phases. Building trust with users and stakeholders in industrial settings is paramount, and the reliability of froth centrifugal slurry pumps contributes significantly to their credibility. Leading manufacturers provide comprehensive support including technical consultation, installation guidance, and after-sales service to ensure optimal performance of their pumps. Case studies from notable operations across the globe reinforce the pumps' reputation, demonstrating their capabilities in maintaining consistent performance under demanding conditions. The future of froth centrifugal slurry pumps steadily aligns with advancements in technology and sustainable practices. Innovations such as remote monitoring and automation are increasingly being integrated into pump systems, offering predictive maintenance capabilities that minimize unexpected downtimes. Additionally, eco-friendly designs are being prioritized, aiming to reduce the carbon footprint associated with industrial slurry pumping operations. In summary, froth centrifugal slurry pumps are a vital component in the realm of industrial pumping solutions, with a design and functionality tailored to handle frothy slurries efficiently. Their impact spans multiple sectors, offering reliability, energy efficiency, and a reduction in operational costs. As industries evolve and face new challenges, these pumps continue to adapt, integrating technological advancements while maintaining their core advantages. Engaging with reputable manufacturers and leveraging comprehensive support services ensures that these pumps fulfill their potential, delivering consistent results in the face of demanding industrial requirements.

Industrial experts have recognized the adaptability of froth centrifugal slurry pumps in diverse applications beyond mining and mineral processing. Industries such as oil sands, chemical processing, and power generation have embraced these pumps due to their ability to efficiently handle frothy mixtures. In oil sands operations, for instance, these pumps enable the transportation of bituminous froth, a challenging task for conventional pump systems, thus optimizing the extraction and processing phases. Building trust with users and stakeholders in industrial settings is paramount, and the reliability of froth centrifugal slurry pumps contributes significantly to their credibility. Leading manufacturers provide comprehensive support including technical consultation, installation guidance, and after-sales service to ensure optimal performance of their pumps. Case studies from notable operations across the globe reinforce the pumps' reputation, demonstrating their capabilities in maintaining consistent performance under demanding conditions. The future of froth centrifugal slurry pumps steadily aligns with advancements in technology and sustainable practices. Innovations such as remote monitoring and automation are increasingly being integrated into pump systems, offering predictive maintenance capabilities that minimize unexpected downtimes. Additionally, eco-friendly designs are being prioritized, aiming to reduce the carbon footprint associated with industrial slurry pumping operations. In summary, froth centrifugal slurry pumps are a vital component in the realm of industrial pumping solutions, with a design and functionality tailored to handle frothy slurries efficiently. Their impact spans multiple sectors, offering reliability, energy efficiency, and a reduction in operational costs. As industries evolve and face new challenges, these pumps continue to adapt, integrating technological advancements while maintaining their core advantages. Engaging with reputable manufacturers and leveraging comprehensive support services ensures that these pumps fulfill their potential, delivering consistent results in the face of demanding industrial requirements.

Latest news

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025