Aug . 07, 2024 07:25 Back to list

Exploring the Features and Benefits of Chinese Centrifugal Dredge Pumps in Modern Applications

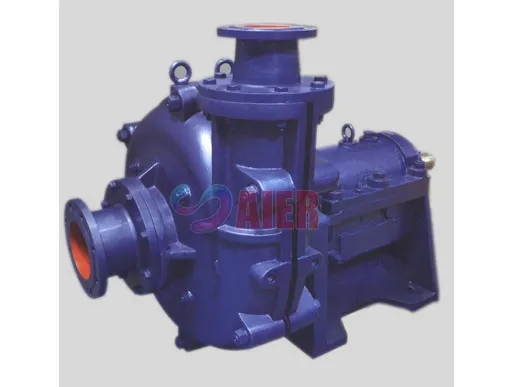

Centrifugal Dredge Pumps The Heart of Dredging Operations in China

Centrifugal dredge pumps play a crucial role in the dredging industry, particularly in China, where extensive waterway management, land reclamation, and mining projects demand reliable and efficient pumping solutions. These pumps are engineered to handle large volumes of sediment, sludge, and water, making them indispensable in various applications such as port construction, river and lake dredging, and hydraulic excavation.

Mechanism and Design

Centrifugal pumps operate on the principle of converting rotational kinetic energy, typically from an impeller, into hydrodynamic energy, resulting in the effective movement of fluids. In dredging applications, these pumps are specially designed to handle abrasive and viscous materials. The construction usually incorporates rugged materials such as high-chrome alloys or rubber linings to withstand the wear and tear associated with dredging operations.

The design of centrifugal dredge pumps often includes features such as adjustable impeller spacing and innovative volute designs. These adaptations enhance the pump's efficiency by optimizing flow patterns, reducing turbulence, and minimizing energy consumption. In the context of China’s booming dredging industry, manufacturers continually innovate to improve pump performance and reduce maintenance needs.

Applications in China

China is home to some of the most significant dredging projects globally, driven by the need for improved shipping channels, flood control measures, and coastal development. For instance, the construction of the new artificial islands in the South China Sea and extensive harbor deepening projects require powerful dredging equipment backed by high-performance centrifugal pumps.

In addition, the Yangtze River, the longest river in Asia, frequently undergoes dredging operations to maintain navigability and prevent sedimentation. Centrifugal dredge pumps are critical in such projects, allowing for the effective removal of sediment and debris while maintaining the delicate ecological balance of the river.

china centrifugal dredge pump

Environmental Considerations

The use of centrifugal dredge pumps is not without its environmental responsibilities. Dredging can disrupt ecosystems, and using efficient and robust pumps helps mitigate such impacts. Modern centrifugal pumps are designed to minimize spillage and improve the precision of material handling, which, in turn, reduces the risk of environmental degradation.

Moreover, advancements in pump technology focus on energy efficiency, which aligns with China’s commitment to sustainability and environmental protection. By investing in more efficient dredging equipment, operators can reduce emissions and lower energy costs, making projects more sustainable in the long run.

The Future of Centrifugal Dredge Pumps in China

As the demand for efficient dredging increases in China, the future of centrifugal dredge pumps appears promising. The ongoing urbanization and infrastructural development in coastal and riverine areas necessitate a robust dredging industry while highlighting the need for innovative solutions.

Moreover, with emerging technologies such as IoT and AI, the prospect of smart dredging solutions is on the horizon. Smart pumps equipped with monitoring systems can provide real-time data on pump performance, wear rates, and maintenance needs. This data-driven approach will not only enhance operational efficiency but also extend the life of dredging equipment.

In conclusion, centrifugal dredge pumps are vital components of China's dredging ecosystem, facilitating a multitude of projects crucial for economic development and environmental management. As the industry evolves, continuous innovation and adherence to sustainability will shape the future of dredging operations, ensuring that these essential tools remain at the forefront of engineering solutions in challenging environments.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025