Oct . 21, 2024 23:41 Back to list

Manufacturer of Spare Parts for Exchangeable Slurry Pumps with High Quality and Reliability

The Importance of Exchangeable Slurry Pump Spare Parts in Industrial Applications

In the world of industrial manufacturing and processing, efficiency and reliability are paramount. Among the essential equipment used in various industries, slurry pumps play a crucial role in transporting mixtures of liquid and solid particles. Slurry pumps are commonly employed in sectors such as mining, mineral processing, wastewater treatment, and construction. However, like all machinery, slurry pumps require maintenance and occasional replacement of parts to ensure optimal performance. This is where the significance of exchangeable slurry pump spare parts comes into play.

Understanding Slurry Pumps

Slurry pumps are designed specifically to handle slurries, which are mixtures of solids and liquids that can vary in viscosity and particle size. These pumps are engineered to move abrasive materials without causing significant wear to the pump components. The functionality of a slurry pump relies heavily on its construction, material selection, and the design of its spare parts.

The Role of Spare Parts

Spare parts are integral to the longevity and effectiveness of slurry pumps. Regular wear and tear, as well as the abrasive nature of the materials being pumped, can lead to deterioration of pump components. Common spare parts include

1. Impellers - The component responsible for creating the flow of the slurry. It's pivotal that impellers are robust and designed to minimize wear. 2. Casing - The outer shell that holds the internal components together and contains the pumped slurry. A durable casing is vital to withstand the pressures of operation.

3. Mechanical Seals - These prevent leaks from occurring in the pump and protect against contamination.

4. Bearings and Bushings - Essential for smooth and efficient operation, these components reduce friction and support rotating parts.

Having access to high-quality spare parts ensures that a slurry pump can be quickly repaired or maintained, minimizing downtime and operational disruption.

The Benefits of Using Exchangeable Spare Parts

1. Cost-Effectiveness Utilizing exchangeable spare parts can significantly reduce repair costs. Instead of replacing whole pumps, operators can simply replace the worn-out components, thus extending the lifespan of the existing equipment.

exchangeable slurry pump spare parts manufacturer

2. Enhanced Performance High-quality exchangeable parts can improve the overall efficiency of slurry pumps. When worn parts are substituted with new, high-performing components, the pump’s operational efficiency improves, leading to better productivity.

3. Reduced Downtime Quick and easy replacement of spare parts minimizes the time a slurry pump is out of commission. This is particularly critical in industries where uninterrupted operation is essential.

4. Customization Manufacturers of slurry pump spare parts often offer customized solutions. Depending on the specific requirements of a project or the type of slurry being transported, tailored parts can enhance performance and reduce wear.

Selecting the Right Manufacturer

Choosing the right manufacturer for exchangeable slurry pump spare parts is vital to ensure quality and reliability. Look for manufacturers with

- Established Track Record Trusted manufacturers with years of experience are likely to produce better quality spare parts.

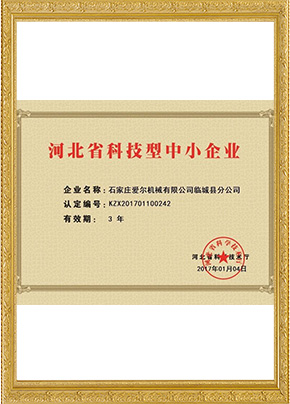

- Quality Certifications Parts that meet industry standards and certifications ensure reliability and performance.

- Customer Support A good manufacturer should provide strong after-sales support, helping clients with installation, maintenance, and troubleshooting.

- Innovation With the rise of new technologies in manufacturing, a supplier that invests in research and development can offer advanced solutions that enhance pump performance.

Conclusion

The effectiveness and longevity of slurry pumps are heavily dependent on the quality of spare parts used in their operation. As industries continue to evolve, so do the demands placed on these pumps. Exchangeable slurry pump spare parts play an essential role in meeting these challenges, ensuring that pumps operate efficiently and reliably. By selecting quality parts from reputable manufacturers, businesses can safeguard their operations, enhance productivity, and reduce overall maintenance costs. The efficient management of slurry pumping systems begins with understanding the critical nature of these components and investing in high-quality, exchangeable spare parts.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025