Dec . 11, 2024 10:19 Back to list

China Slurry Pump Spare Parts Manufacturers and Suppliers for High-Quality Solutions

Understanding China Warman Slurry Pump Spare Parts Factories

The importance of reliable slurry pumps in various industrial applications cannot be understated. Among the leading brands in the slurry pump market is Warman, known for its robust construction and high-efficiency performance. To ensure that these pumps operate at their peak, maintaining a supply of quality spare parts is essential. This is where China’s Warman slurry pump spare parts factories come into play, playing a critical role in the global supply chain for these components.

The Role of Spare Parts

Spare parts are critical for the maintenance and repair of any pumping system. In industrial environments, slurry pumps often handle abrasive and corrosive substances, leading to wear and tear. Regular maintenance and timely replacements can prevent costly downtimes, ensuring that operations run smoothly. Consequently, the demand for high-quality spare parts has surged, and Chinese manufacturers have emerged as key players in meeting this demand.

Advantages of Chinese Manufacturers

1. Cost-Effective Solutions One of the primary advantages of sourcing slurry pump spare parts from China is cost efficiency. Factories in China generally operate with lower labor and production costs, allowing them to offer competitive pricing for their products without compromising on quality.

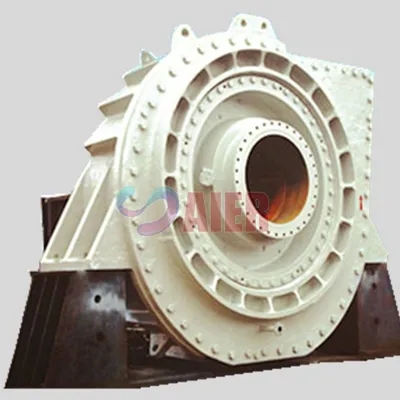

2. Wide Variety of Parts Chinese factories are capable of producing a vast range of spare parts, including impellers, liners, and seals specifically designed for Warman slurry pumps. This variety ensures that customers can find the exact components they need for maintenance or upgrades.

3. Advanced Manufacturing Technologies Many Chinese factories have adopted advanced manufacturing technologies and quality control measures, ensuring that the spare parts meet international standards. With continuous improvements in production processes, manufacturers can produce high-quality components that match or exceed OEM specifications.

4. Customization Options Sourcing from Chinese manufacturers often comes with the option for customization. Whether it’s specific materials or particular designs, many factories are willing to work with clients to create tailor-made solutions that meet unique operational requirements.

china warman slurry pump spare parts factories

Challenges in the Market

Despite the numerous advantages, there are challenges associated with sourcing spare parts from China. Communication barriers can sometimes lead to misunderstandings in custom orders. Additionally, differences in quality control standards might mean that some suppliers do not meet the desired specifications.

To mitigate these challenges, it is essential for buyers to conduct thorough due diligence. Engaging directly with manufacturers, visiting factories, and requesting samples can significantly reduce risks and ensure that the parts acquired are of the highest quality.

Quality Assurance and Certification

Quality assurance is a prominent concern when sourcing spare parts, given the rigorous operational demands placed on slurry pumps. Reputable Chinese manufacturers often adhere to international quality standards such as ISO 9001, which outlines the criteria for effective quality management systems. Certifications like these can help buyers identify reliable suppliers.

Moreover, many factories engage in testing procedures to ensure that each part performs optimally before it is shipped. These tests can range from material composition analyses to pressure testing to guarantee durability and performance under operational conditions.

Conclusion

The landscape of Warman slurry pump spare parts procurement is increasingly dominated by Chinese manufacturers. Their cost-effective, versatile, and high-quality components make them appealing to industries that rely on efficient pumping solutions. However, buyers must remain vigilant in their sourcing strategies, ensuring they partner with reputable factories that prioritize quality assurance.

By investing time in research and maintaining open communication with suppliers, industries can secure the necessary spare parts that will keep their Warman slurry pumps operating efficiently, ultimately leading to enhanced productivity and reduced maintenance costs. As the demand for reliable slurry pumps continues to grow, the role of Chinese manufacturers in this sector will undoubtedly expand, solidifying their status as key players in the global market.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025