Nov . 12, 2024 05:46 Back to list

china warman slurry pump mechanical seal manufacturer

Understanding China Warman Slurry Pump Mechanical Seal Manufacturers

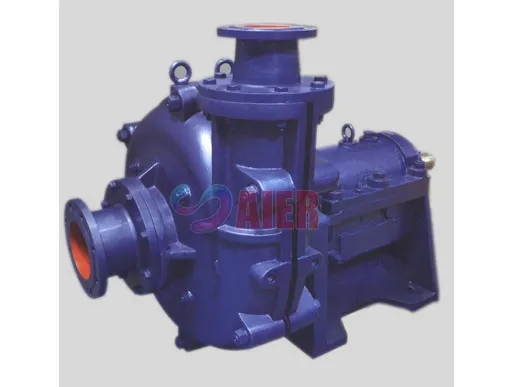

The mining and mineral processing industries rely heavily on the efficiency and durability of their equipment, and one essential component in this sector is the slurry pump. Among the leaders in this field, China has made significant strides, particularly with manufacturers that specialize in Warman slurry pump mechanical seals. These seals are crucial in ensuring the operational reliability and longevity of slurry pumps, which are designed to handle abrasive and corrosive materials.

The Role of Mechanical Seals in Slurry Pumps

Mechanical seals are critical components in any pump system, serving as barriers that prevent the escape of liquids and gases. In slurry pumps, where the transported materials can be highly abrasive and variable in consistency, the mechanical seal faces even greater challenges. It must endure extreme pressures, varying temperatures, and the erosive nature of slurries. A well-engineered mechanical seal minimizes the risk of leaks, reduces downtime caused by maintenance, and improves overall pump efficiency.

The functionality of mechanical seals is fundamentally tied to their design and the materials used in their manufacture. Commonly, these seals are constructed from advanced materials such as silicone carbide, tungsten carbide, and various elastomers, which help them withstand wear and tear over time. Manufacturers in China have invested significantly in R&D to develop high-quality seals that can cope with the demanding requirements of modern slurry pumping applications.

Chinese Manufacturers Leading the Way

China is home to several manufacturers of Warman-style slurry pumps and their accompanying mechanical seals. Companies such as Shijiazhuang Ouwang Pump Co., Ltd., and others have established themselves as key players in the slurry pump market. These manufacturers not only produce pump assemblies but also focus on the development of high-performance mechanical seals tailored for specific applications.

These companies often leverage advanced technologies and engineering expertise to ensure their products meet international standards. They employ rigorous testing methods to guarantee that the mechanical seals will perform under the extreme conditions expected in mining, mineral processing, and other industrial environments. Furthermore, many of these manufacturers are ISO-certified, reflecting their commitment to quality and customer satisfaction.

china warman slurry pump mechanical seal manufacturer

Advantages of Sourcing from China

Sourcing mechanical seals and slurry pumps from Chinese manufacturers offers several advantages. Cost efficiency is often highlighted; however, it is the combination of competitive pricing and robust quality that attracts global customers. With lower labor costs and access to a wide range of raw materials, Chinese manufacturers can offer high-quality products at a fraction of the price found in Western countries.

Moreover, these manufacturers usually have extensive experience dealing with international clients, making them adept at meeting different specifications and standards. They can customize mechanical seals to match the specific requirements of various applications, enhancing the functionality of slurry pumps and extending their operational lifespan.

Challenges and Considerations

Despite the advantages, sourcing from China does come with challenges. Issues such as communication barriers, variations in quality, and concerns over intellectual property rights can arise. Thus, it is essential for international buyers to conduct thorough research and engage with reputable manufacturers that have proven track records.

Additionally, potential customers should consider logistics and shipping times, especially for large equipment like slurry pumps. Partnering with a reliable supplier who understands the intricacies of the shipping process can mitigate such risks.

Conclusion

China's robust manufacturing sector has positioned it as a leading provider of Warman slurry pump mechanical seals. By focusing on high-quality production and innovative designs, these manufacturers contribute greatly to the efficiency and reliability of slurry pumping systems worldwide. For industries reliant on such equipment, choosing the right mechanical seal can lead to significant improvements in operational performance, making the effort to connect with reputable Chinese manufacturers well worth it. As the global demand for efficient mineral processing continues to rise, the importance of these suppliers will only grow, underscoring the significance of strong manufacturing relationships in the industry.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025