Nov . 08, 2024 19:55 Back to list

china vertical sump pump

Understanding China Vertical Sump Pumps Design, Applications, and Benefits

Vertical sump pumps play a crucial role in various industries, particularly in situations that involve the handling of liquids with solid content or requiring efficient drainage in confined spaces. In China, the production and application of vertical sump pumps have gained significant traction due to increasing industrial demands and environmental considerations.

What is a Vertical Sump Pump?

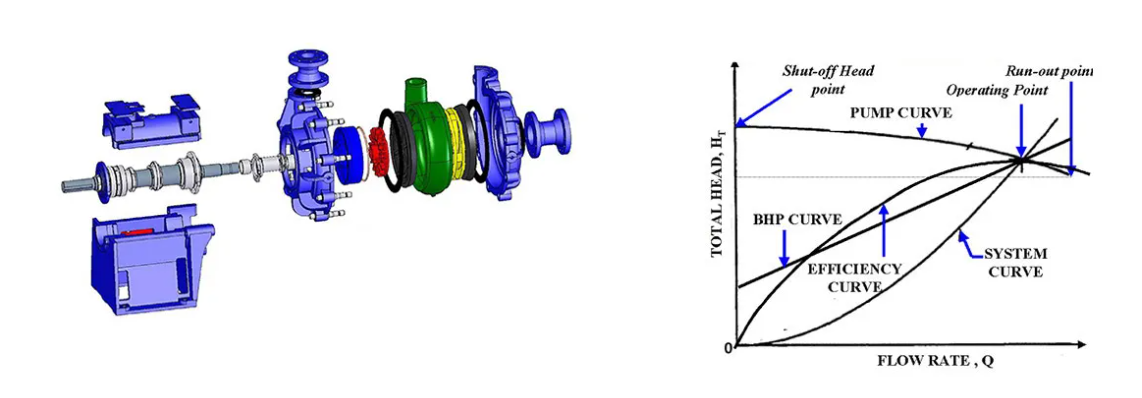

A vertical sump pump is a type of submersible pump specifically designed to operate in a vertical orientation, which allows for effective lifting and transportation of liquids from submerged conditions. These pumps are characterized by their long shaft design, which typically extends from the motor to the impeller located at the bottom of the pump casing. This design allows the pump to operate efficiently in sumps, pits, or tanks where the liquid level may fluctuate.

Design Features

China's vertical sump pumps are engineered to be robust and durable, capable of handling a wide range of applications. Key design features typically include

1. Materials Made from corrosion-resistant materials such as stainless steel or special alloys, these pumps can handle abrasive and corrosive liquids, extending their lifespan.

2. Impeller Design The impellers are often designed in various configurations (e.g., vortex, semi-open, or closed) to suit different applications. This adaptability allows the pumps to handle solids and provide high-efficiency flow rates.

3. Adjustment Mechanism Many vertical sump pumps feature adjustable discharge heights, which enhance their versatility. This means that the pumps can be utilized in varying operational environments without the need for significant modifications.

4. Sealing and Bearing Systems Advanced sealing and bearing systems are employed to prevent leaks and reduce maintenance needs, ensuring reliability in continuous operation.

Applications

Vertical sump pumps are widely utilized in various sectors, including

china vertical sump pump

- Mining Used for dewatering operations and handling slurry, these pumps help manage water levels in mining pits efficiently.

- Wastewater Management Employed in treatment plants, these pumps move wastewater or sewage to different treatment stages while accommodating solids and debris.

- Industrial Applications In manufacturing facilities, vertical sump pumps manage process water and coolant removal, ensuring equipment operates smoothly.

- Construction Sites During excavation and foundation work, these pumps are essential for managing groundwater and surface water.

Benefits of Using Vertical Sump Pumps

1. Space Efficiency The vertical design minimizes the footprint required for installation, making it ideal for applications in confined or space-limited areas.

2. High Performance Capable of pumping large volumes of liquid while handling solids effectively, these pumps are suitable for heavy-duty applications.

3. Reduced Maintenance With fewer moving parts and robust design, vertical sump pumps generally require less maintenance than traditional horizontal pumps.

4. Cost-Effective Operation By effectively managing high volumes of liquid and solids without frequent maintenance or replacement, these pumps contribute to lower operational costs.

Conclusion

As industries continue to evolve and face challenges related to liquid handling, vertical sump pumps, particularly those manufactured in China, stand out due to their innovative designs and versatility. Their ability to manage a variety of applications, coupled with efficiency and reliability, makes them an essential component in many industrial processes. With ongoing advancements in pump technology and manufacturing, the future of vertical sump pumps looks promising, ensuring that they will remain integral to efficient industrial operations.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025