Nov . 30, 2024 12:09 Back to list

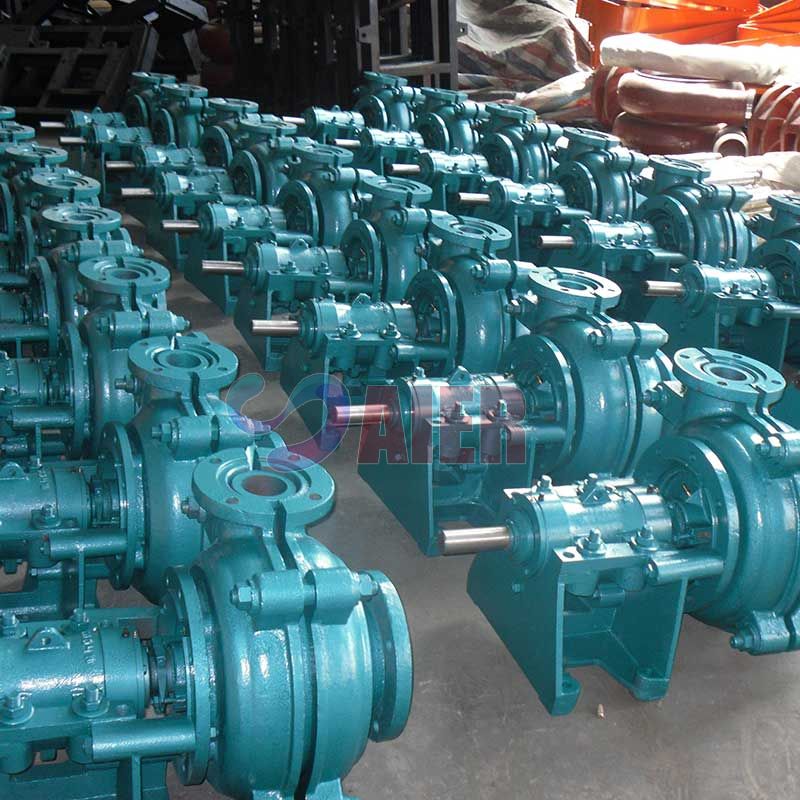

China Slurry Pump Factory Providing Durable Sump Pumps and Replacement Parts for Industry Needs

Exploring the Importance of Slurry Sump Pumps and Spare Parts in China

In the realm of industrial applications, slurry sump pumps play a crucial role in transporting abrasive and viscous materials across various sectors, including mining, construction, and wastewater management. As industries expand and evolve, the demand for efficient and reliable slurry sump pumps, alongside their spare parts, has significantly increased. This article delves into the significance of slurry sump pumps and the factory landscape in China that supports this vital component of industrial machinery.

Understanding Slurry Sump Pumps

Slurry sump pumps are specially designed to handle solid-laden liquids, allowing for the efficient movement of sludge, slurry, and other thick mixtures. Their applications are broad, encompassing sectors like mining, where they are used to transport ore slurry, and wastewater treatment plants, where they help manage sediment and sludge removal. These pumps are engineered to withstand harsh conditions, characterized by both wear from abrasive materials and the challenges posed by high viscosity and density.

Given the critical nature of their function, reliable performance is key. The efficiency and durability of slurry sump pumps directly impact operational costs and productivity. As such, industries continuously seek advanced designs and innovations to improve pump performance, reduce energy consumption, and extend service life.

The Role of Spare Parts

Maintaining the efficiency of slurry sump pumps requires a steady supply of high-quality spare parts. Over time, components such as impellers, wear plates, and seals can degrade and necessitate replacement to ensure continued optimal performance. The availability of reliable spare parts within the supply chain is crucial, as it minimizes downtime and operational disruptions.

The importance of sourcing spare parts from reputable manufacturers cannot be overstated. Inferior quality parts can lead to increased wear and tear on the pump, resulting in higher maintenance costs and potential system failures. In contrast, using original or high-standard replacement parts facilitates better compatibility and performance, ensuring that the pump operates as intended.

china slurry sump pump and spare parts factory

The Chinese Market for Slurry Sump Pumps

China has emerged as a key player in the global manufacturing of slurry pumps and their spare parts. The country boasts numerous factories specializing in the production of these critical components. Chinese manufacturers are increasingly recognized for their capabilities in providing both cost-effective and technologically advanced solutions to domestic and international markets.

With rapid industrialization and infrastructural development, China's need for efficient slurry management solutions has surged. This has encouraged factories to innovate and optimize their production processes, focusing on enhancing the quality and efficiency of their pumps. Moreover, with advancements in materials technology, Chinese manufacturers are now able to produce pumps that exhibit greater resistance to corrosion and wear, which is crucial for handling abrasive slurries.

Innovations and Future Trends

Recent trends within the slurry sump pump industry indicate a move toward increased automation and integration of smart technologies. Manufacturers are exploring options that include IoT (Internet of Things) capabilities, which allow for real-time monitoring of pump performance. This innovation not only improves operational efficiency but also provides predictive maintenance insights, reducing the likelihood of unexpected machine failures.

Additionally, sustainability in pump design is gaining traction, with a focus on reducing energy consumption and utilizing eco-friendly materials. As global awareness of environmental issues continues to grow, the slurry pump manufacturing sector in China is likely to adopt practices that align with sustainability goals.

Conclusion

In conclusion, slurry sump pumps and their spare parts are integral to various industrial applications, significantly impacting operational efficiency and costs. China's manufacturing sector plays a pivotal role in supplying these essential components, characterized by innovation and an emphasis on quality. As industries look toward the future, advancements in technology and sustainability will shape the evolution of slurry pumps, ensuring they remain essential tools in the management of abrasive and viscous materials.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025