Nov . 08, 2024 22:15 Back to list

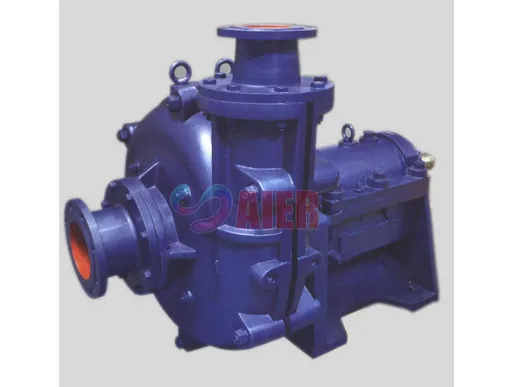

china slurry pump for vapour blasting factory

The Rise of Slurry Pumps in Vapour Blasting Factories in China

In recent years, China has witnessed a significant transformation in its manufacturing sector, particularly in the field of surface preparation technologies. Among the most critical components facilitating this change is the slurry pump. These pumps have become indispensable in the vapour blasting process, which is rapidly gaining popularity due to its efficiency and eco-friendliness. This article will explore the importance of slurry pumps in vapour blasting factories, their operational principles, and the benefits they offer.

What is Vapour Blasting?

Vapour blasting, also known as wet blasting, combines water and abrasive media to create a superior surface finish on various materials, including metals, plastics, and glass. This process reduces dust and minimizes health risks compared to traditional dry blasting methods. The use of moisture in vapour blasting helps in cooling the surface and preventing damage while enhancing the cleaning effectiveness. This innovative approach has made vapour blasting a preferred choice in industries ranging from automotive to aerospace.

The Role of Slurry Pumps

At the heart of the vapour blasting process is the slurry pump, which moves the abrasive slurry mixture—comprising water and granulated media—through the blasting machines. These pumps are designed to handle various types of slurries, including those containing heavy abrasives like aluminum oxide or glass beads. Slurry pumps are essential for maintaining a consistent flow and pressure, which are crucial for achieving optimal blasting results.

Operational Principles

Slurry pumps operate based on the centrifugal principle, where an impeller driven by a motor rotates and imparts kinetic energy to the slurry. This energy converts into pressure, allowing the slurry to flow through the pump and into the vapour blasting equipment. Most slurry pumps used in vapour blasting are equipped with wear-resistant materials to withstand the abrasive nature of the media and ensure long operational life. Additionally, these pumps often feature adjustable settings to optimize performance according to the specific requirements of each blasting task.

china slurry pump for vapour blasting factory

Benefits of Using Slurry Pumps in Vapour Blasting

1. Efficiency Slurry pumps enable a continuous and reliable flow of abrasive material, enhancing the efficiency of the vapour blasting operation. This reliability translates into reduced downtime and increased productivity within the factory.

2. Quality Surface Finish The controlled flow and pressure provided by slurry pumps allow for a more uniform application of the abrasive media, resulting in improved surface finishes. Factories utilizing these pumps can achieve higher standards of quality in their products.

3. Reduced Waste The use of slurry pumps optimizes the consumption of abrasive materials and water, leading to reduced waste. This not only lowers operational costs but also aligns with growing environmental concerns regarding waste management in manufacturing processes.

4. Safety By minimizing dust production, slurry pumps contribute to a safer working environment for factory employees. This safety feature is particularly important in industries where respiratory health is a concern.

5. Versatility Slurry pumps can handle a wide variety of abrasive media, making them adaptable to different applications. This versatility allows vapour blasting factories to cater to diverse client needs without investing in multiple pumping systems.

Conclusion

The integration of slurry pumps into vapour blasting factories marks a crucial development in China's manufacturing landscape. As industries strive for efficiency and quality in surface preparation, the role of these pumps cannot be overstated. By ensuring a consistent supply of abrasive slurry, they enhance the effectiveness of the vapour blasting process, contributing to better product outcomes and environmental sustainability. With the ongoing advancements in pump technology, one can anticipate further innovations that will continue to propel the vapour blasting industry forward, solidifying China's position as a leader in modern manufacturing.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025