Nov . 10, 2024 13:41 Back to list

China Replacement Parts for Interchangeable Slurry Pumps from Reliable Factories

Understanding China’s Interchangeable Slurry Pump Spare Parts Factories

In recent years, the demand for efficient and reliable slurry pumps has surged across various industries, including mining, construction, and wastewater management. As a vital component of these industries, slurry pumps are designed to transport abrasive and viscous fluids. However, like any machinery, they require regular maintenance and the timely replacement of spare parts. This article delves into the significance of interchangeable slurry pump spare parts factories in China and what they bring to the global market.

The Rise of the Slurry Pump Industry

Slurry pumps play a crucial role in conveying mixtures of solid and liquid materials. The need for these pumps is particularly pronounced in sectors where the movement of heavy slurries is commonplace. With China's rapid industrial growth, the country has established itself as a leading manufacturer of slurry pumps and their associated spare parts. The proliferation of these factories in China can be attributed to several factors, including low production costs, advanced engineering capabilities, and a robust supply chain.

Interchangeability A Key Feature

One of the most appealing aspects of slurry pump spare parts manufactured in China is their interchangeability. Manufacturers focus on creating parts that can be easily swapped with those from existing pump systems. This feature significantly reduces the downtime associated with maintenance and repair, allowing companies to keep their operations running smoothly. Interchangeable parts also create a competitive pricing environment, as operators can procure components from various suppliers without being tied to a single brand’s proprietary parts.

Quality Standards and Certifications

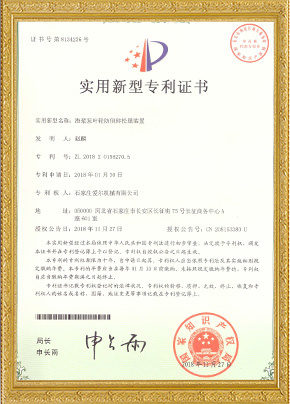

china interchangeable slurry pump spare parts factories

Chinese manufacturers of interchangeable slurry pump spare parts are increasingly aware of the importance of quality assurance. Many factories adhere to international quality standards such as ISO 9001, ensuring that their products meet the required specifications for durability and reliability. Additionally, several manufacturers are investing in advanced technology and materials, such as high-chromium alloys, which enhance the performance and lifespan of slurry pump components. By obtaining various certifications, these factories not only increase their credibility but also appeal to international buyers seeking reliable spare parts that meet specific performance criteria.

The Supply Chain Ecosystem

China's robust supply chain ecosystem is another aspect that elevates its position in the global market for slurry pump spare parts. With a well-established network of suppliers, logistics companies, and distribution channels, factories can efficiently source raw materials and deliver finished products to customers worldwide. This efficiency translates into faster production times and a higher capacity to meet urgent demands. Furthermore, the geographical location of many manufacturing hubs enables cost-effective shipping to various regions, making Chinese spare parts more accessible to operators across the globe.

Sustainability and Future Trends

As industries worldwide focus more on sustainability, many Chinese slurry pump spare parts manufacturers are also looking for ways to reduce their environmental impact. Innovations in materials science are leading to the development of more sustainable alternatives for traditional materials used in manufacturing. Furthermore, as competition grows, manufacturers are embracing eco-friendly practices, from energy-efficient production processes to waste reduction strategies.

Conclusion

China's interchangeable slurry pump spare parts factories play a pivotal role in meeting the global demand for efficient and reliable pumping solutions. With an emphasis on quality, interchangeability, and a robust supply chain, these factories are well-positioned to support industries reliant on slurry pumps. As technology advances and environmental concerns become increasingly critical, the future of these factories will likely include innovative products and sustainable practices, ensuring their continued leadership in the global market. Thus, as industries look for dependable partners in the supply of slurry pump components, China’s manufacturers remain a top choice, driven by efficiency, quality, and the ability to adapt to changing market demands.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025