Oct . 19, 2024 06:10 Back to list

china high pressure pump for detergent slurry manufacturer

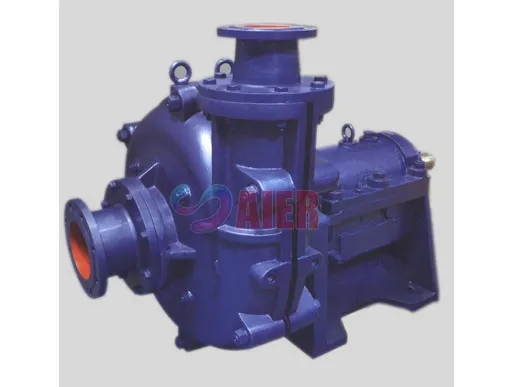

The Role of Chinese High-Pressure Pumps in Detergent Slurry Manufacturing

In the rapidly evolving landscape of industrial manufacturing, high-pressure pumps have emerged as essential components, particularly in the production of detergent slurries

. These pumps play a pivotal role in ensuring efficiency, durability, and product quality. Among the leading suppliers in this domain, Chinese manufacturers have gained significant recognition for their advanced technology and competitive pricing, positioning themselves as key players in the global market.High-pressure pumps are designed to handle viscous and abrasive materials, which are characteristic of detergent slurries. Detergent production often involves mixing various chemical compounds to create effective cleaning agents, necessitating the movement of thick, foamy slurries through the manufacturing line. Traditional pumping systems can struggle with these materials, leading to operational inefficiencies and increased maintenance costs. In contrast, high-pressure pumps are engineered to deliver consistent pressure and flow rates, ensuring that the production process runs smoothly and without interruptions.

Chinese manufacturers have leveraged their engineering expertise and technological advancements to develop high-performance high-pressure pumps specifically tailored for detergent slurry applications. These pumps are designed to withstand the harsh operating conditions typically found in chemical processing plants. With features such as robust materials, corrosion resistance, and enhanced sealing mechanisms, Chinese high-pressure pumps ensure durability and reliability over extended periods.

china high pressure pump for detergent slurry manufacturer

Moreover, the competitive pricing offered by Chinese manufacturers makes their pumps an attractive option for both domestic and international companies. In an industry where operational costs can significantly affect the bottom line, investing in efficient equipment is crucial. Chinese high-pressure pumps provide companies with the opportunity to enhance their production capabilities without compromising on quality or breaking the budget.

The global demand for environmentally friendly and effective cleaning products has also accelerated the need for efficient detergent production. High-pressure pumps facilitate the rapid mixing and pumping of ingredients, allowing manufacturers to respond quickly to market trends and consumer preferences. As such, these pumps not only improve operational efficiency but also enable manufacturers to innovate and introduce new products to meet the evolving needs of consumers.

In conclusion, the contribution of Chinese high-pressure pumps in detergent slurry manufacturing cannot be overstated. Their advanced engineering, durability, and cost-effectiveness have made them indispensable tools in the production process. As the demand for high-quality detergents continues to rise, reliance on these high-pressure pumps will likely grow, driving further innovations in the industry. Companies looking to optimize their production processes would do well to consider investing in these state-of-the-art pumps provided by reputable Chinese manufacturers. Their commitment to quality and performance makes them a smart choice for businesses aiming to enhance their manufacturing efficiency and product competitiveness in the global market.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025