Nov . 08, 2024 04:13 Back to list

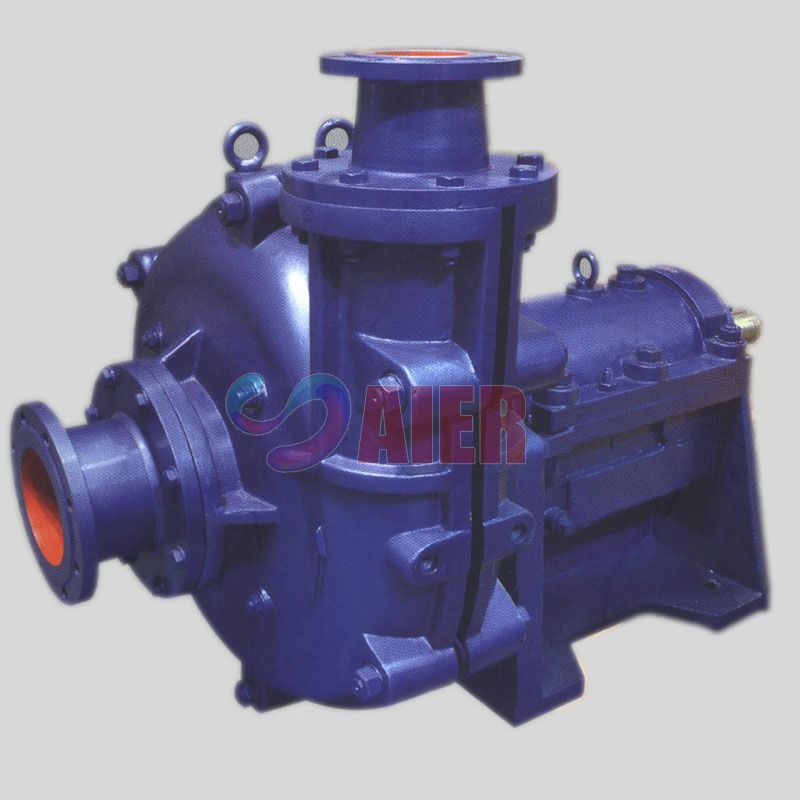

China's Leading Factories for Close Impeller Type Slurry Pumps and Their Innovations

Exploring the World of China’s Close Impeller Type Slurry Pump Factories

In the industrial landscape, slurry pumps play a pivotal role in the transportation of mixtures of liquid and solid materials. Among these, close impeller type slurry pumps are particularly noteworthy due to their efficient design and operational capabilities. As one of the leading manufacturers of such machinery, China has established a significant presence in the global market, contributing innovative technologies and high-quality products that cater to various sectors including mining, chemical processing, and wastewater management.

Understanding Close Impeller Type Slurry Pumps

Close impeller type slurry pumps are distinguished by their impeller design which minimizes the clearance between the impeller and the pump casing. This specific design feature allows for enhanced efficiency and reduces the potential for wear and tear, making them optimal for handling abrasive and viscous slurries. The close impeller effectively generates higher hydraulic efficiency, which translates into better performance and reduced operational costs.

This pump type is particularly suited for applications that involve transporting corrosive or abrasive materials, making them invaluable in industries such as mining, where slurry comprised of water and finely crushed minerals is common. Their robust construction and superior hydraulic performance enable these pumps to handle challenging conditions seamlessly, ensuring continuous operation even in demanding environments.

The Role of Chinese Factories in Production

China has become a powerhouse in the manufacturing of slurry pumps, with numerous factories specializing in various types of slurry pump technologies, including close impeller designs. These factories leverage advanced production techniques, stringent quality control measures, and a deep understanding of the technological requirements necessary to produce reliable and high-performance equipment.

Chinese manufacturers are known for their ability to produce large quantities of slurry pumps at competitive prices, thereby meeting the needs of both local and international markets. They utilize state-of-the-art machinery and sophisticated designs to improve pump longevity and efficiency, often incorporating materials that enhance resistance to wear and corrosion. By focusing on innovation and technology, these factories have positioned themselves as key players in the slurry pump industry.

Advantages of Sourcing from China

china close impeller type slurry pump factories

1. Cost-Effectiveness One of the primary advantages of sourcing close impeller type slurry pumps from China lies in the cost-effectiveness. The scale of production and the reduced labor costs in China allow manufacturers to offer competitive prices while maintaining acceptable quality standards. This is especially beneficial for businesses looking to optimize capital expenditure.

2. Diverse Product Range Chinese factories provide a wide range of slurry pump models and specifications, allowing customers to choose products that best meet their operational needs. This variety includes different size options, material grades, and customizable features to accommodate various applications.

3. Advanced Technology Many Chinese manufacturers invest heavily in R&D and technology upgrades, resulting in products that incorporate the latest advancements in pump engineering. This commitment to innovation ensures that buyers receive machinery that is not only efficient but also adaptable to rapidly changing industry demands.

4. Robust Supply Chains The well-established supply chains in China facilitate seamless procurement and distribution, ensuring timely delivery of products. This logistical efficiency increasingly attracts global customers who require reliable and prompt service.

Challenges and Considerations

Despite the advantages, there are some challenges associated with sourcing from Chinese factories. Quality inconsistency can sometimes be a concern, particularly with numerous players in the market. It is essential for buyers to conduct thorough due diligence and select reputable manufacturers known for their commitment to quality standards and customer service.

Additionally, language barriers and time-zone differences can pose difficulties in communication. However, many factories have multilingual staff and customer service teams to assist international buyers, mitigating these issues effectively.

Conclusion

China’s close impeller type slurry pump factories exemplify the intersection of innovation and efficiency within the manufacturing sector. With their considerable expertise, advanced technologies, and extensive product offerings, these factories play a vital role in fulfilling the global demand for specialized pumping solutions. As industries continue to evolve, the significance of reliable slurry pumps in operational processes cannot be understated, and China is poised to remain at the forefront of this critical manufacturing domain, driving both quality and innovation in the years to come.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025