Nov . 23, 2024 22:59 Back to list

Centrifugal Wastewater Pump Manufacturers and Suppliers in China for Reliable Solutions

Centrifugal Wastewater Pumps in China Driving Forces of Innovation and Efficiency

Centrifugal wastewater pumps play a pivotal role in the management of water resources, particularly in industries where effective waste removal is crucial. As urbanization and industrialization continue to accelerate in China, the demand for efficient and reliable wastewater management solutions has surged. This demand has fueled the growth of centrifugal wastewater pump factories across the country, positioning China as a global leader in pump manufacturing.

One of the primary driving forces behind the expansion of centrifugal wastewater pump factories in China is the rapid pace of urban development. Over the past few decades, millions of people have migrated to urban areas, creating significant challenges related to waste management and sanitation. In response, local governments have invested heavily in infrastructure development, including sewage treatment plants and drainage systems, necessitating advanced pumping solutions to facilitate effective wastewater treatment and transport.

Chinese manufacturers have risen to the challenge by focusing on innovation and efficiency in their centrifugal pump designs. These pumps are characterized by their ability to move fluids through rotational energy, making them ideal for various wastewater applications. Manufacturers have implemented advanced technologies, such as energy-efficient motors, smart control systems, and durable materials, to enhance pump performance and longevity. This emphasis on innovation not only meets domestic needs but also positions Chinese centrifugal pumps competitively in the global market.

A key factor contributing to the success of centrifugal wastewater pump factories in China is the nation's robust manufacturing infrastructure. With a well-established supply chain and access to a vast pool of skilled labor, Chinese manufacturers can produce pumps at scale while maintaining high-quality standards. Additionally, advancements in automation and manufacturing technology have further streamlined production processes, allowing for faster turnaround times and reduced costs.

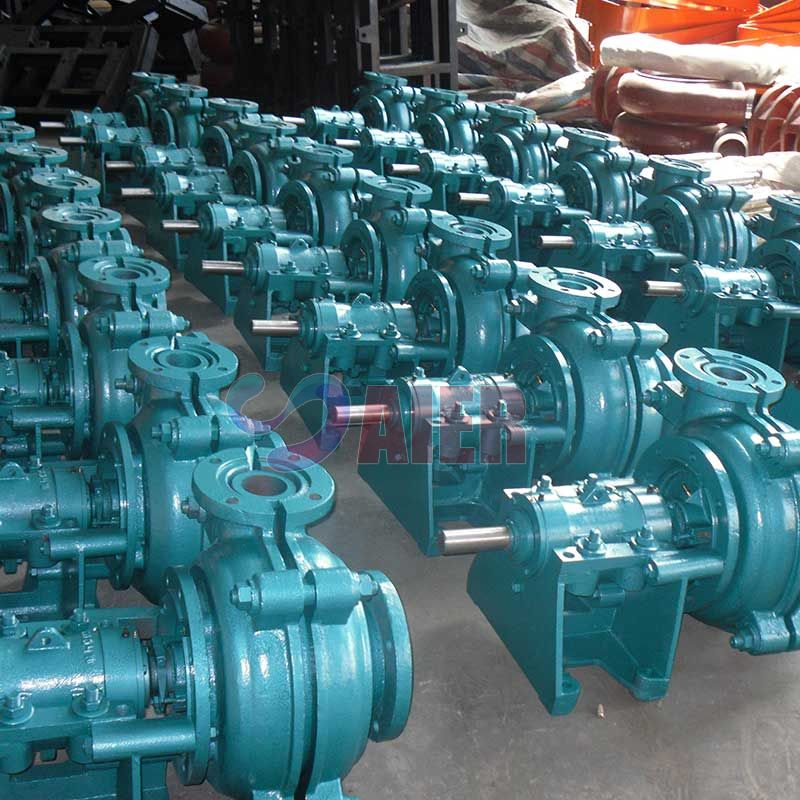

china centrifugal wastewater pump factories

Moreover, many factories are adopting environmentally sustainable practices in their operations. This shift is driven by increasing awareness of environmental issues and regulatory pressures aimed at reducing pollution. Factories are investing in eco-friendly materials and processes, ensuring that their products not only meet performance standards but also align with global sustainability goals. This proactive approach helps manufacturers cater to the growing market segment that prioritizes environmentally responsible products.

The global market for centrifugal wastewater pumps is also witnessing significant growth, driven by rising awareness of water scarcity and the need for efficient wastewater treatment solutions. Chinese manufacturers are strategically positioning themselves to tap into international markets by enhancing their export capabilities. Trade agreements and partnerships have facilitated the expansion of Chinese centrifugal pumps into regions such as Southeast Asia, Africa, and Europe, where infrastructure development is crucial to support growing populations.

As the centrifugal wastewater pump industry continues to evolve, manufacturers in China are likely to focus on research and development to improve performance further and reduce energy consumption. Collaboration with research institutions and universities can facilitate innovation, ensuring that Chinese factories remain at the forefront of technological advancements in pump manufacturing.

In conclusion, centrifugal wastewater pump factories in China are playing a critical role in addressing the challenges of wastewater management in rapidly urbanizing regions. By focusing on innovation, efficiency, and sustainability, these manufacturers are not only meeting domestic needs but also positioning themselves as global competitors. As the demand for advanced wastewater solutions continues to grow, Chinese centrifugal pump factories are poised to make significant contributions to both environmental sustainability and industrial efficiency, leading the way in this essential industry.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025