Dec . 17, 2024 01:34 Back to list

China Centrifugal Slurry Pump Manufacturers and Suppliers for Industrial Applications

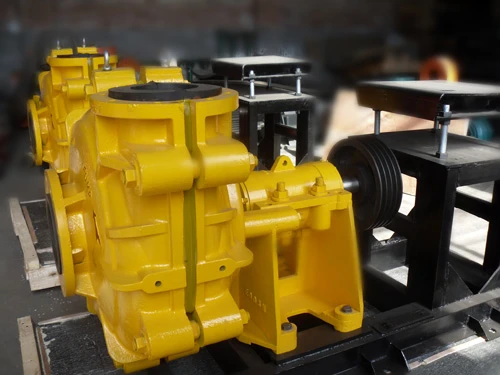

The China Centrifugal Slurry Pump A Look into Warman Factories

Centrifugal slurry pumps have become essential in various industries, including mining, metallurgy, and construction, thanks to their ability to handle abrasive and viscous materials. Among the prominent names in the manufacturing of these pumps is the Warman brand, renowned for its robust engineering and reliable performance. This article delves into the features and benefits of Warman centrifugal slurry pumps, the manufacturing processes in China, and their widespread applications.

Understanding Centrifugal Slurry Pumps

Centrifugal slurry pumps are designed to transport slurry – a mixture of liquids and solids – efficiently. These pumps operate on the principle of centrifugal force, which involves converting kinetic energy from the rotating impeller into hydrodynamic energy in the slurry. This efficient design allows for easy handling of challenging substances, such as coal, mineral ore, and waste materials, which are prevalent in industries that require pumping solutions.

Warman's Legacy in Slurry Pump Manufacturing

Warman International, a brand with a long history in pump engineering, has established itself as a leader in the slurry pump market. With origins dating back to the 1930s, the company has consistently innovated its product offerings and manufacturing techniques. Warman pumps are recognized for their durability, efficiency, and ability to operate in extreme conditions, making them a preferred choice for professionals in various sectors.

Manufacturing Processes in China

China has become the epicenter of slurry pump manufacturing, and many Warman factories have established themselves in this competitive landscape. The manufacturing process involves several critical stages, including material selection, casting, machining, assembly, and rigorous testing.

1. Material Selection Quality begins with selecting the right materials. Warman pumps typically use high-chrome alloys, which offer excellent resistance to wear and corrosion, essential for handling abrasive materials.

2. Casting Precision casting methods allow for intricate pump components to be produced, ensuring optimal fit and function. This stage sets the foundation for durability and performance.

china centrifugal slurry pump warman factories

3. Machining Advanced CNC machining technology is utilized for precision engineering of pump components. This enhances part accuracy and ensures each pump meets stringent specifications.

4. Assembly After machining, components are skillfully assembled. The assembly process emphasizes quality control, with each pump inspected for alignment, bearing clearance, and overall structural integrity.

5. Testing Before pumps leave the factory, they undergo comprehensive performance testing. This includes checking flow rates, pressure performance, and the ability to handle various slurry compositions.

Applications and Advantages

Warman centrifugal slurry pumps are widely used in several industries. In mining, they are crucial for transporting mineral slurries, while in the coal sector, they move coal-slurry mixtures efficiently. The construction industry relies on them for transporting concrete and other materials that require resilient pumping solutions.

The advantages of Warman centrifugal slurry pumps are manifold

- Durability Engineered from high-quality materials to withstand harsh environments. - Efficiency Designed to minimize energy consumption while maximizing flow rates. - Versatility They can handle various types of slurry, making them suitable for diverse applications. - Ease of Maintenance Warman pumps are designed for quick disassembly and reassembly, facilitating routine maintenance.

Conclusion

As industries continue to evolve, the demand for reliable and efficient pumps remains steadfast. The Warman brand, particularly through its Chinese manufacturing facilities, stands out in the realm of centrifugal slurry pumps. With a commitment to quality, innovation, and customer satisfaction, Warman continues to cater to the ever-growing needs of industries that depend on effective slurry transportation. The continued investment in technology and manufacturing processes ensures that Warman remains at the forefront of slurry pump solutions, contributing significantly to sector advancements worldwide. Whether in mining, construction, or any application requiring high-performance pumping, Warman centrifugal slurry pumps are synonymous with quality and reliability.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025