Nov . 19, 2024 04:36 Back to list

china centrifugal slurry pump parts factories

Centrifugal Slurry Pump Parts in China An Overview of Factories and Manufacturing Excellence

In the realm of industrial applications, centrifugal slurry pumps play a vital role in transporting abrasive and viscous materials across various sectors, including mining, mineral processing, and construction. As the demand for efficient and durable pumping solutions grows, China has emerged as a key player in the production of centrifugal slurry pump parts. This article explores the factories involved in this industry, their manufacturing capabilities, and the significance of their products on a global scale.

The Importance of Centrifugal Slurry Pumps

Centrifugal slurry pumps are designed to handle liquids that contain solid particles, making them indispensable in industries where material transport is critical. These pumps facilitate the movement of slurry—a mixture of substances such as water, minerals, sand, and ore—ensuring smooth operations within various processes. Their design allows them to cope with the challenges posed by wear and tear from abrasive materials, making the choice of quality parts crucial for optimal performance.

China's Role in Manufacturing Slurry Pump Parts

China's industrial landscape boasts a multitude of factories specializing in the production of centrifugal slurry pump parts. These facilities utilize advanced manufacturing techniques and stringent quality control processes to deliver components that meet international standards. The proliferation of these factories can be attributed to the country's significant investments in industrial infrastructure and a skilled workforce adept in engineering and manufacturing disciplines.

Key Components of Slurry Pumps

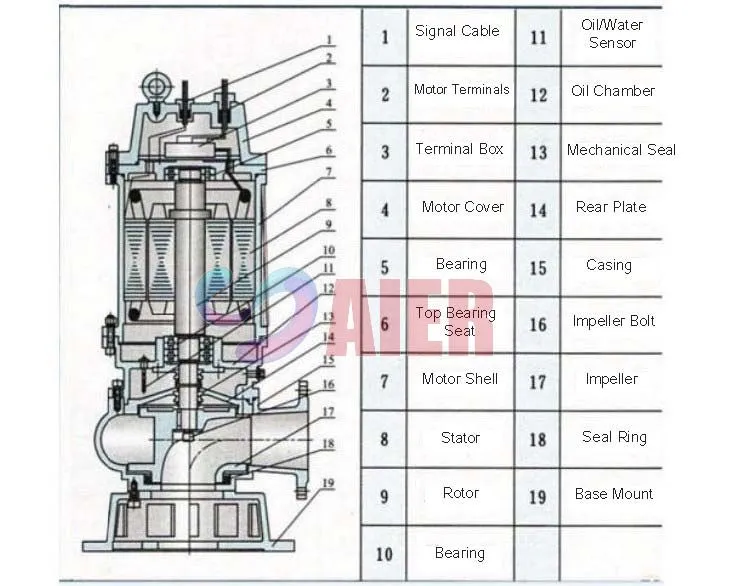

The primary parts of a centrifugal slurry pump include the casing, impeller, shaft, bearings, and suction and discharge flanges

. Each of these components plays a critical role in the pump's overall performance1. Casing The casing encases the impeller and ensures that the pumped slurry flows efficiently through the system. It needs to be robust, as it withstands high pressures and corrosive materials.

2. Impeller The impeller is the heart of the pump, imparting kinetic energy to the slurry. It must be designed to minimize wear while maximizing flow rates.

china centrifugal slurry pump parts factories

3. Shaft The shaft connects the impeller to the motor and transmits power. It must be both strong and flexible enough to handle operational stresses.

4. Bearings Bearings support the shaft and reduce friction during operation, ensuring smooth and efficient pump performance.

5. Suction and Discharge Flanges These components facilitate the connection of the pump to piping systems, allowing for effective transport of slurry.

Quality Control in Manufacturing

Chinese factories are well aware of the importance of quality in manufacturing slurry pump parts. Many adopt internationally recognized quality management systems such as ISO 9001, which ensures that production processes are efficient and that products meet customer specifications. Regular inspections, performance testing, and rigorous material selection are standard practices that help maintain the integrity and durability of the components produced.

Global Market Influence

With a focus on innovation and quality, Chinese factories have established a strong foothold in the global market for slurry pump parts. Many companies export their components to regions such as North America, Europe, and Australia, where they have gained a reputation for providing cost-effective and high-quality solutions. The competitive pricing, coupled with the ability to customize products to meet specific needs, further strengthens China's position in the industry.

Conclusion

The centrifugal slurry pump parts manufacturing industry in China has evolved into a robust sector characterized by innovation, quality, and competitiveness. With an array of factories dedicated to producing high-performance components, China continues to influence the global market significantly. As industries worldwide seek reliable and efficient solutions for material transport, the importance of quality slurry pump parts cannot be overstated. The advancements in technology and manufacturing processes in China will likely drive future developments in the centrifugal slurry pump market, ensuring that industries remain equipped to handle their most challenging operational demands.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025