Nov . 11, 2024 14:26 Back to list

china centrifugal slurry pump liner factories

The Importance of Centrifugal Slurry Pump Liners in China’s Industrial Landscape

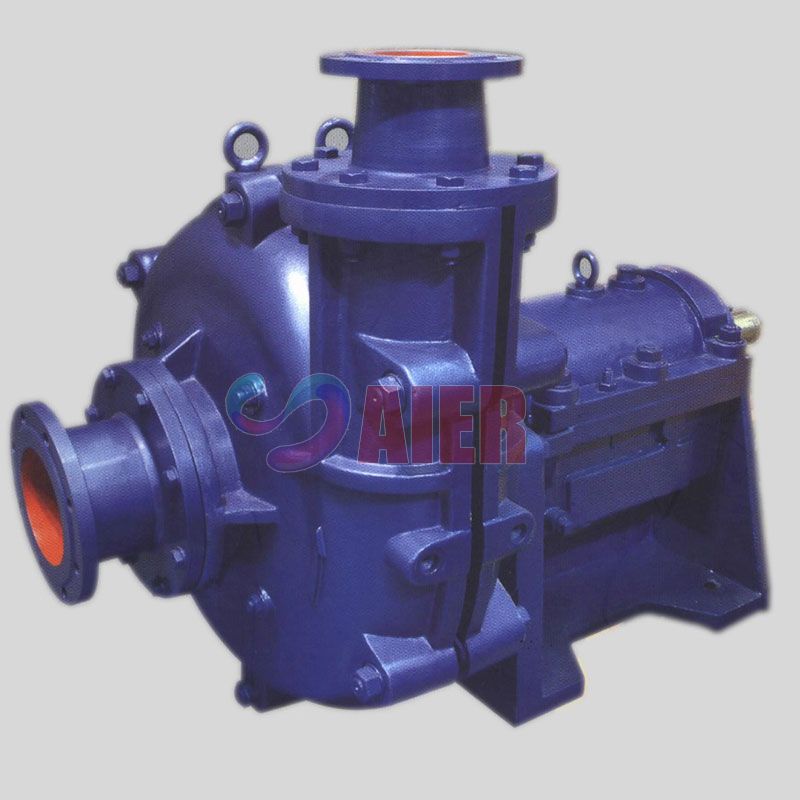

In the realm of industrial machinery, slurry pumps play a pivotal role in various applications, particularly in sectors like mining, construction, and wastewater management. Among the different components of a slurry pump, the liner is crucial as it directly impacts the efficiency, durability, and performance of the pump. In recent years, China's centrifugal slurry pump liner factories have gained prominence, contributing significantly to both domestic and international markets.

Understanding Centrifugal Slurry Pumps

Centrifugal slurry pumps are designed to transport abrasive and viscous slurries, which consist of solids suspended in liquids. The construction of these pumps typically includes a casing, impeller, shaft, and liner. The liner is particularly important as it acts as a barrier between the pumped slurry and the pump components, protecting the latter from wear and tear. The choice of material for the liner is critical, as it must withstand the aggressive nature of the slurries while maximizing operational efficiency.

The Role of Liner Materials

Liners are typically made from various materials such as rubber, hard metal, and ceramic composites. Each material has its advantages depending on the type of slurry being pumped. For example, rubber liners are often favored for their flexibility and resistance to impact, making them suitable for less abrasive slurries. In contrast, hard metal liners are preferred for more abrasive materials due to their strength and durability.

Given the diverse range of industries in China that rely on centrifugal slurry pumps, the demand for high-quality liners has surged. Factories in China have focused on producing liners that meet international standards, providing a competitive edge in both quality and pricing.

Innovations in Manufacturing

china centrifugal slurry pump liner factories

The advancement of manufacturing technologies has enabled Chinese factories to enhance the quality of centrifugal slurry pump liners. Many manufacturers are now employing sophisticated techniques such as precision casting, CNC machining, and state-of-the-art molding processes to create liners that meet specific performance criteria. These innovations not only improve the lifespan of the liners but also reduce maintenance costs for end-users.

Moreover, quality control practices in these factories have been significantly improved. Rigorous testing procedures, including wear resistance tests and pressure tests, are now commonplace to ensure that the liner can withstand the demands of various pumping applications. This focus on quality has helped Chinese manufacturers establish themselves as reliable suppliers in the global market.

Economic Impact

The production of centrifugal slurry pump liners is not only an industrial endeavor but also a vital contributor to China's economy. By establishing a robust manufacturing base for these products, China has created numerous job opportunities and has fostered a supply chain that includes raw material suppliers, component manufacturers, and logistics providers. This interdependence helps stimulate economic growth and innovation within the industry.

Additionally, exports of high-quality slurry pump liners have positioned China as a key player in the global market. Countries that depend on mining and mineral processing, or those dealing with wastewater treatment, often look towards China for reliable and cost-effective pumping solutions. This trend underscores the significant role that China's factories play in supporting global industrial operations.

The Future of Slurry Pump Liners in China

As industries evolve and the demand for efficient slurry handling systems increases, the future of centrifugal slurry pump liner production in China looks promising. Manufacturers are continuously exploring new materials and technologies to further enhance the performance of their products. Environmental considerations are also becoming a focal point, with a shift towards sustainable production practices and recyclable materials.

In summary, China's centrifugal slurry pump liner factories are crucial to the country's industrial ecosystem. Through innovative manufacturing processes and robust quality controls, these factories are producing high-quality liners that meet global standards. As the demand for efficient and durable slurry handling solutions grows, China is well-positioned to lead in this vital segment of the industrial machinery market, driving advancements that will benefit various sectors and contribute to overall economic development.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025