Nov . 19, 2024 22:41 Back to list

china best pump for slurry factory

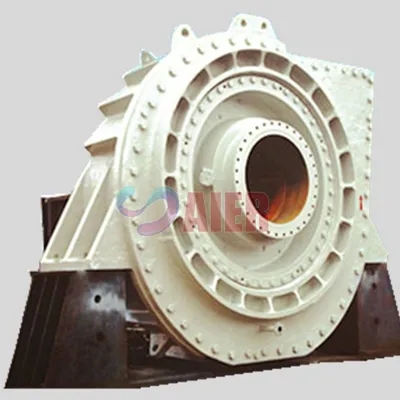

Choosing the Best Pump for Slurry Applications in China

When it comes to handling slurry, selecting the right pump is crucial for efficiency and reliability in industrial processes. China, being a hub for manufacturing and mining activities, has a plethora of pump options tailored specifically for slurry applications. Understanding the characteristics of slurry and the different types of pumps available can help industries make informed choices that enhance productivity and reduce maintenance costs.

Understanding Slurry

Slurry is a mixture of solids and liquids, commonly found in mining, construction, and wastewater treatment applications. Its viscosity can vary significantly, depending on the concentration of solids and the nature of the liquid. This variability makes slurry handling challenging, requiring specialized pumping solutions designed to manage solid particles without clogging or causing excessive wear.

Types of Slurry Pumps

In China, the most common types of pumps used for slurry applications include

1. Centrifugal Slurry Pumps These pumps are designed to move slurry with high efficiency. They utilize centrifugal force to transport the mixture, making them suitable for applications with lower solid concentrations. However, their performance can be affected by the viscosity of the slurry, and they might require frequent maintenance if used for highly abrasive materials.

2. Positive Displacement Pumps These pumps are ideal for handling thick and viscous slurries. They work by trapping a fixed volume of slurry and forcing it through the pump. This makes them suitable for applications where the solid content is high. However, they can be slower and more complex than centrifugal pumps.

3. Submersible Slurry Pumps As the name suggests, these pumps are submerged in the slurry. They are beneficial for applications in confined spaces or deep pits. Submersible slurry pumps are highly efficient for dewatering tasks but require specific considerations regarding wear and tear from abrasive materials.

china best pump for slurry factory

Considerations When Choosing a Slurry Pump

When selecting the best slurry pump for industrial applications in China, several factors should be taken into account

1. Slurry Composition Understanding the composition of the slurry, including the size, shape, and density of the solid particles, will dictate the type of pump that will work best. Pumps designed to handle abrasive materials are essential to prolong service life.

2. Pump Material The construction material of the pump is crucial for durability. Common materials include rubber, stainless steel, and hard metal. The choice depends on the abrasive nature of the slurry and the required resistance to corrosion.

3. Flow Rate and Head Requirement Evaluate the necessary flow rate and the total dynamic head (TDH) to ensure the pump can effectively move the slurry over the required distance and height.

4. Energy Efficiency With rising energy costs and increased environmental awareness, selecting a pump that minimizes energy consumption while maximizing efficiency is vital.

5. Maintenance and Service Regular maintenance is paramount to the longevity of pumps. Choose manufacturers that provide excellent after-sales service and easy access to spare parts.

Conclusion

In conclusion, the best pump for slurry applications in China depends on various factors, including the specific requirements of the slurry being handled. By understanding the different types of slurry pumps available and considering critical factors such as composition, material, and efficiency, industries can enhance their operations and reduce downtime. Embracing advanced slurry pumping technologies will undoubtedly contribute to the overall competitiveness of China's manufacturing and mining sectors, ensuring they remain robust and efficient in the global market.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025