Oct . 02, 2024 11:49 Back to list

Top Suppliers of High-Quality Pumps for Lime Slurry in China

Choosing the Best Pump for Lime Slurry from China Suppliers

When it comes to handling lime slurry, selecting the right pump is crucial to ensure efficiency, longevity, and optimal performance. Lime slurry, a mixture of lime and water, is used in various industries, including mining, wastewater treatment, and construction, for its ability to neutralize acidity, stabilize materials, and improve water quality. Given the increasing demand for reliable pumping solutions, many suppliers from China are stepping up to provide high-quality products tailored for lime slurry applications.

Key Considerations for Lime Slurry Pumps

1. Material Compatibility Lime slurry can be abrasive and corrosive, requiring pumps made from materials resistant to wear and tear. High-quality materials such as stainless steel, rubber-lined cast iron, or plastics specifically designed to withstand such conditions are essential. A pump that can endure the abrasive nature of lime will have a longer lifespan and lower maintenance costs.

2. Pump Type Different types of pumps serve various functions in lime slurry applications. Centrifugal pumps are widely used for their efficiency and simplicity, while positive displacement pumps may be better suited for applications requiring high pressure and consistent flow rates. It’s crucial to assess the specific needs of your operation to select an appropriate pump type.

3. Flow Rate and Pressure Understanding the required flow rate and pressure for your lime slurry application is vital. Suppliers should provide detailed specifications on the pump's capacity to ensure it meets your operational demands. Over-specifying can lead to unnecessary costs, while under-specifying can result in decreased efficiency and potential system failures.

4. System Integration The pump must seamlessly integrate with the existing system. This integration involves not only the physical piping and fittings but also the overall design of the pumping system. Ensuring that the pump's capacity and size fit well within the system parameters is essential for creating a streamlined process.

china best pump for lime slurry suppliers

5. Maintenance and Serviceability Regular maintenance is crucial for the longevity of any pump. When choosing a supplier, consider those that offer comprehensive service packages and support. Look for pumps that are easy to service and have readily available replacement parts. A supplier committed to after-sales service can help minimize downtime and reduce operational costs.

Top Chinese Suppliers of Lime Slurry Pumps

China hosts a plethora of suppliers who specialize in pumps tailored for lime slurry applications. Suppliers like Shijiazhuang Naipu Pump Co., Ltd., and Jiangxi Naipu Mining Machinery and New Materials Co., Ltd. are recognized for their robust, efficient pumps tailored to industrial needs. They often provide customizable solutions, ensuring that customers receive products that perfectly match their specifications.

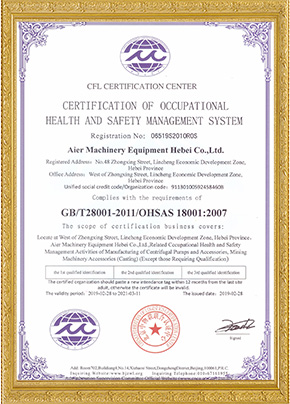

These suppliers focus on innovative technologies and manufacturing processes to enhance performance, reliability, and energy efficiency. Additionally, many of them are ISO certified, which affirms their commitment to quality standards and customer satisfaction.

Conclusion

Selecting the right pump for lime slurry applications is a critical decision that can significantly impact operational efficiency and cost-effectiveness. By thoroughly evaluating the material compatibility, pump type, flow rate, integration capabilities, and maintenance requirements, you can make an informed choice. Moreover, sourcing pumps from reputable Chinese suppliers known for their quality and service can provide an added advantage in establishing a reliable pumping system. As industry demands evolve, investing in the best pump technology is not just an operational choice but a strategic decision for long-term success.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025