Sep . 06, 2024 03:14 Back to list

High-Quality China Metal Slurry Pump Parts | Durable & Reliable Solutions

Understanding China Metal Slurry Pump Parts An Overview

Metal slurry pumps are vital components in numerous industrial applications, particularly in sectors such as mining, mineral processing, and wastewater management. In China, the demand for high-quality metal slurry pump parts has surged due to the rapid growth of industries relying on effective material handling solutions. This article explores the significance, types, and manufacturing trends of metal slurry pump parts in China.

The Importance of Metal Slurry Pumps

Slurry pumps are designed to handle abrasive and corrosive fluids containing solids. They are essential for transporting mixtures of liquid and solid particles, such as minerals, coal, and industrial waste. The efficiency and durability of these pumps are largely determined by their components, making the manufacture of high-quality pump parts critical for ensuring optimal performance and longevity.

Key Components of Metal Slurry Pumps

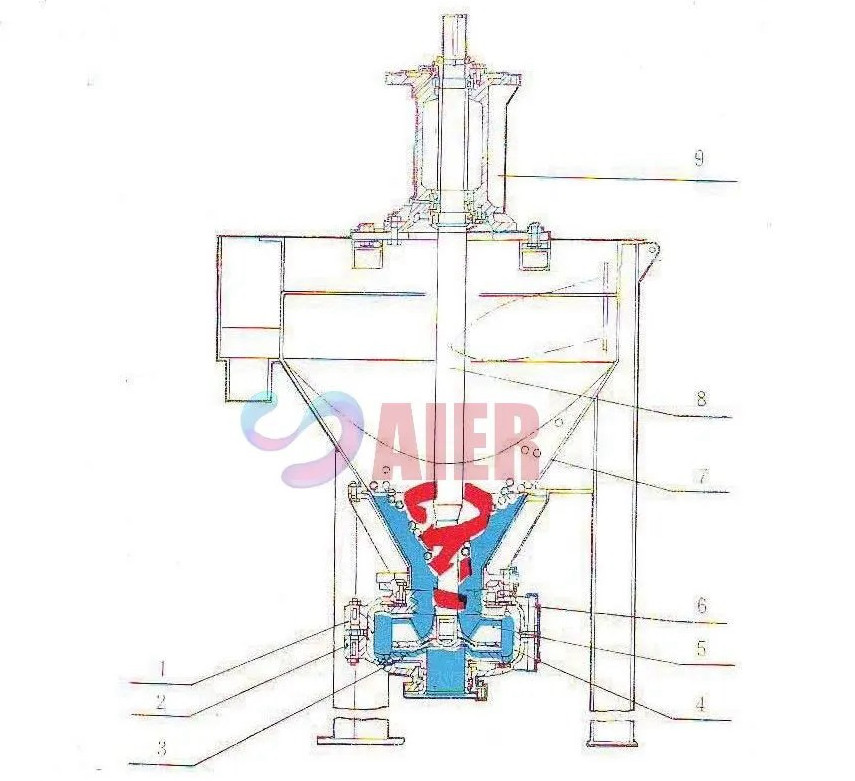

The essential parts of a metal slurry pump include

1. Pump Shell Typically constructed from high-strength metals like chromium alloy, the pump shell is built to withstand severe conditions and abrasion caused by the slurry's solid content.

2. Impellers These are crucial for converting rotational energy into hydraulic energy. Impellers in slurry pumps are often made from hardened materials to resist wear and tear.

3. Seals Sealing systems prevent leakage and maintain the efficiency of the pump. Metal seals are commonly used in high-pressure applications to withstand the harsh conditions that these pumps operate under.

china metal slurry pump parts

4. Bearings Bearings support the rotating shaft and are designed to endure heavy loads while maintaining smooth operation. They are often made from materials that provide excellent wear resistance.

5. Discharge and Suction Liners These parts play a critical role in controlling the flow of the slurry. They are typically lined with abrasion-resisting materials to extend their lifespan under harsh operating conditions.

Manufacturing Trends in China

China has become a global leader in the production of metal slurry pump parts, driven by advanced manufacturing technologies and a vast supply chain network. The use of Computer Numerical Control (CNC) machining, 3D printing, and other innovative techniques has enabled manufacturers to produce intricate designs with high precision and efficiency.

Furthermore, many Chinese manufacturers emphasize research and development to enhance the materials used in pump parts. The introduction of advanced alloys and composite materials has improved the performance and durability of slurry pumps, enabling them to handle an even wider range of applications.

Quality Assurance and Certification

To compete in the global market, Chinese manufacturers are increasingly focusing on quality assurance and obtaining certifications such as ISO 9001. This commitment to quality ensures that the metal slurry pump parts produced meet international standards, further enhancing their credibility and appeal to global markets.

Conclusion

In conclusion, metal slurry pump parts are integral to the efficiency and longevity of slurry pumps in various industrial applications. With China's burgeoning manufacturing sector, the country is poised to maintain its position as a leading supplier of high-quality metal slurry pump components. As industries continue to evolve, the demand for innovative, durable, and efficient pump parts will only grow, making it imperative for manufacturers to invest in advanced technology and quality control to meet these needs.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025