Sep . 30, 2025 11:05 Back to list

China High Pressure Slurry Pump Manufacturers—High Head OEM?

Inside China’s High-Pressure Slurry Pump Scene: What Buyers Should Really Know

If you’ve been shopping parts from china high pressure slurry pump manufacturers, you’ll know two things: the market moves fast, and the best vendors quietly invest in metallurgy and QA rather than splashy booths. I’ve walked a few foundry floors; the difference shows in the throatbush and impeller wear faces long before it shows on your maintenance sheet.

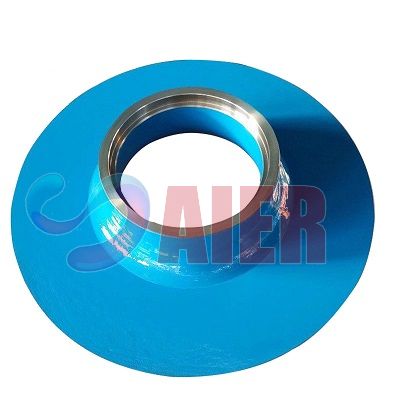

Today’s pick is the G10083A05 high chrome throatbush—essentially a replacement Warman pump throatbush—from Aierpumps. It targets harsh duties where discharge pressure stays elevated and solids content is, frankly, ugly. Trends? Higher solids, more recycled water (abrasive), and tighter ESG reporting. To be honest, uptime is the real KPI customers chase.

Where it works (and why)

- Mining concentrators: cyclone feed, ball mill discharge, tailings transfer

- Dredging and sand/gravel: high head booster lines

- Coal prep plants: dense media and slurry transfer

- FGD and process slurries: where chloride levels aren’t extreme

Many customers say the right throatbush extends the service window enough to align with planned outages—small thing, big savings.

Product snapshot: G10083A05 high chrome throatbush

| Part | G10083A05 (Warman-compatible throatbush) |

| Material | High chrome white iron A05 (≈26–28% Cr), ASTM A532 Class III Type A |

| Hardness (HRC) | ≈59–64 HRC (real-world use may vary) |

| Pressure envelope | Up to ≈2.0 MPa system pressure depending on pump size and casing rating |

| Finish & QC | UT/PT on critical sections, spectrochemical analysis, ISO 6508-1 hardness checks |

| Typical service life | +15–35% vs generic 23–25% Cr, depending on p80 and velocity |

Process flow and testing (quick tour)

Materials: high-purity Fe-Cr with controlled Mo and Nb additions for carbide stability. Methods: resin sand casting, controlled solidification; then quench-and-temper to refine M7C3 carbides. Machining on datum faces; trial fit with gland/liner seats. Testing: chemical OES, UT on heavy sections, hardness per ISO 6508-1; pump performance verified on ISO 9906 rigs (acceptance grade 2B for many lots). It seems boring—until your shutdown is four hours shorter.

Vendor snapshot (real-world buyer notes)

| Vendor | Certs | Lead time | Notes |

|---|---|---|---|

| Aierpumps | ISO 9001, material traceability | ≈2–4 weeks ex-works | Consistent Cr spec, provides test coupons and reports |

| Generic trader | Varies | 1–6 weeks | Pricey airfreight options; QC inconsistent—check hardness maps |

| OEM rebuild shop | OEM procedures | 3–8 weeks | Top dimensional fit; premium pricing |

Customization that actually matters

- Alloys: A05 standard; A49 or elastomer options for corrosive or lower velocity duties

- Clearance tuning: matched with impeller to control recirculation at high heads

- Hardfacing: localized tungsten carbide on wear lips (case-by-case)

Field data and case notes

Iron ore plant, cyclone feed line (3.2–3.6 m/s, p80 ≈250 μm): G10083A05 throatbush ran 4,100 hours vs 3,050 hours baseline (+34%). Lab abrasion (ASTM G65 Proc. A) internal test coupons: 0.12 g loss vs 0.17 g on a generic 24% Cr sample. Customers also reported easier alignment on reinstall—small chamfer tweak, surprisingly helpful.

If you’re shortlisting china high pressure slurry pump manufacturers, ask for: full heat lot chemistry, hardness map across sections, UT results, and pump test sheets per ISO 9906 or ANSI/HI. And yes, request pictures of the gating/risering—tells you a lot about porosity risk.

Advantages at a glance

- High M7C3 carbide fraction for sliding abrasion resistance

- Stable performance at higher discharge pressures and recycled process water

- Traceability and standardized QA—less guesswork, more uptime

References

- ASTM A532/A532M – Abrasion-Resistant Cast Irons specification.

- ISO 9906 – Rotodynamic pumps, hydraulic performance acceptance tests.

- ANSI/HI 12.1–12.6 – Rotodynamic slurry pumps for nomenclature, definitions, and applications.

- ISO 6508-1 – Metallic materials, Rockwell hardness test.

Note: performance figures are indicative; site conditions and slurry PSD/chemistry will influence results.

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025