Aug . 30, 2025 01:20 Back to list

China High Pressure Slurry Pump Manufacturers - Quality & High Head

Navigating the Landscape of High-Pressure Slurry Pumps in China

In the demanding sectors of mining, metallurgy, power generation, and chemical processing, the efficient and reliable transfer of abrasive and corrosive slurries is paramount. This critical task is often entrusted to high-pressure slurry pumps, engineered to withstand extreme operating conditions. China has emerged as a global leader in the manufacturing of such specialized equipment, with numerous enterprises dedicated to innovation and quality. For businesses seeking robust and efficient solutions, understanding the capabilities of china high pressure slurry pump manufacturers is essential. This article delves into the industry trends, technical intricacies, application diversity, and reliability aspects offered by these manufacturers.

Current Industry Trends and Market Dynamics

The market for high-pressure slurry pumps is experiencing significant growth, driven by an increased global demand for raw materials and the expansion of heavy industries. Key trends influencing china high pressure slurry pump manufacturers include:

- Technological Advancements: Continuous investment in R&D leads to pumps with enhanced wear resistance, higher efficiency, and greater automation. Innovations in material science, such as advanced high-chrome alloys and ceramic composites, are extending service life and reducing maintenance costs.

- Energy Efficiency: With rising energy costs and stricter environmental regulations, there is a strong emphasis on developing pumps that consume less power while maintaining optimal performance. This includes optimized hydraulic designs and advanced motor control systems.

- Customization and Modularity: Manufacturers are increasingly offering tailored solutions to meet specific application requirements, from unique material configurations for corrosive slurries to modular designs that allow for easier maintenance and parts replacement.

- Smart Pumping Solutions: Integration of IoT and AI for predictive maintenance, real-time monitoring, and remote diagnostics is becoming a standard feature, allowing for proactive intervention and minimized downtime.

- Global Competitiveness: Chinese manufacturers are increasingly competing on quality, performance, and after-sales support, moving beyond traditional cost advantages to establish themselves as reliable global suppliers of `china high head slurry pump manufacturers` solutions.

The demand for `high quality submersible slurry pump` and `high quality chemical centrifugal slurry pump` underscores the market's need for specialized, durable equipment capable of handling the most challenging industrial fluids.

The Meticulous Manufacturing Process of High-Pressure Slurry Pumps

The production of a reliable `china high pressure slurry pump` is a complex undertaking, involving precise engineering and rigorous quality control. Leading china high pressure slurry pump manufacturers follow a detailed multi-stage process to ensure each pump meets the highest performance and durability standards.

Process Flow: From Design to Dispatch

- Design and Simulation: Utilizing advanced CAD/CAE software, engineers design pump hydraulics, casing, impellers, and critical components like the throatbush. Finite Element Analysis (FEA) simulates stress distribution and fluid dynamics to optimize performance, minimize wear, and maximize energy efficiency. This stage defines the specifications for `high head centrifugal slurry pump` performance.

-

Material Selection and Preparation:

Materials are chosen based on the intended slurry characteristics (abrasion, corrosion, temperature). Common materials include:

- High-Chrome Alloy: For extreme abrasion, e.g., A05 (27% Cr), A07, A49. Components like impellers and the G10083A05 high chrome throatbush are often made from these alloys to ensure extended service life. This particular throatbush is critical for maintaining hydraulic efficiency and resisting wear at the pump's inlet.

- Natural Rubber/Elastomers: For fine, abrasive slurries with impact.

- Polyurethane: For corrosive and mildly abrasive applications.

- Stainless Steel: For highly corrosive, non-abrasive slurries (e.g., Duplex, Super Duplex for `high quality chemical centrifugal slurry pump`).

- Casting: Critical components like casings, impellers, and liners are typically cast. Precision casting ensures complex geometries are formed accurately, minimizing material stress and maximizing flow efficiency. Advanced foundries employ vacuum-assisted casting and heat treatment processes to achieve optimal metallurgical properties.

- Forging: Shafts and other high-stress components may undergo forging to enhance grain structure and improve mechanical strength and fatigue resistance.

- CNC Machining: After casting or forging, components are precision machined using Computer Numerical Control (CNC) equipment to achieve tight tolerances and smooth surface finishes. This is vital for balancing rotating parts and ensuring perfect fitment, crucial for the performance of `high pressure pump for detergent slurry`.

- Assembly: Skilled technicians assemble the pump, paying close attention to seal installation, bearing lubrication, and alignment of rotating components. Proper assembly is critical for pump efficiency and longevity.

-

Testing and Quality Control: Every pump undergoes rigorous testing.

- Hydrostatic Testing: To verify casing integrity under high pressure.

- Performance Curve Testing: Measures head, flow, power consumption, and efficiency against design specifications, often adhering to ISO 9906 (Centrifugal Pump Test) and ANSI/HI standards.

- Vibration and Noise Analysis: Ensures smooth operation and adherence to operational safety limits.

- Material Composition Analysis: Spectroscopic analysis to confirm alloy composition and quality.

- Surface Treatment and Finishing: Application of protective coatings (e.g., epoxy paint, ceramic lining) to resist external corrosion and enhance durability.

- Packaging and Shipment: Pumps are securely packaged for transit, often with customized crating to prevent damage during international shipping.

This meticulous approach ensures that the pumps delivered by china high pressure slurry pump manufacturers are not only robust but also perform reliably in the most challenging industrial environments, providing an extended service life and minimizing total cost of ownership.

Technical Specifications and Performance Parameters

The performance of a `china high pressure slurry pump` is defined by several critical technical parameters that dictate its suitability for specific applications. Understanding these specifications is key for industrial engineers and procurement specialists.

Key Parameters for High-Pressure Slurry Pumps

- Discharge Head (H): Measured in meters (m) or feet (ft), this indicates the vertical height the pump can lift the slurry. For `high head centrifugal slurry pump` or `high head submersible slurry pump`, this parameter can exceed 100 meters, essential for long-distance pipelines or deep mining operations.

- Flow Rate (Q): Expressed in cubic meters per hour (m³/h) or gallons per minute (GPM), this is the volume of slurry the pump can move per unit time. High-capacity pumps can achieve flow rates well over 5,000 m³/h.

- Solids Handling Capability: Defined by the maximum particle size (mm) and slurry concentration (by weight or volume) the pump can effectively handle without clogging or excessive wear. This is crucial for applications like `high pressure gold dredge pump`.

- Efficiency (η): The ratio of hydraulic power delivered to the fluid to the shaft power input, typically expressed as a percentage. Modern designs aim for efficiencies above 70%, with some reaching 85%, significantly impacting operational costs.

- Power (P): The motor power required to drive the pump, usually in kilowatts (kW). This directly relates to the pump's head and flow rate and the density of the slurry.

- NPSH Requirements (Net Positive Suction Head): Critical for preventing cavitation, which can severely damage pump components. NPSH required by the pump must be less than the NPSH available from the system.

- Wear Life of Components: Measured in operating hours, this is a testament to the material quality and design, particularly for parts like impellers, liners, and the throatbush (e.g., G10083A05 high chrome throatbush).

Illustrative Product Specification Table

Below is an example of typical specifications for a high-pressure slurry pump offered by leading china high pressure slurry pump manufacturers, demonstrating the range and capabilities available.

| Parameter | Value/Range | Units |

|---|---|---|

| Model Series | AHS-200E | - |

| Discharge Diameter | 200 (8") | mm (inches) |

| Flow Rate (max) | 1080 | m³/h |

| Total Head (max) | 90 | m |

| Efficiency (BEP) | 78 | % |

| Max Particle Size | 75 | mm |

| Motor Power (typical) | 160 - 350 | kW |

| Casing Material | High Chrome Alloy (A05) / Ductile Iron with rubber lining | - |

| Impeller Material | High Chrome Alloy (A05) | - |

These specifications highlight the robust engineering and material science that go into creating pumps capable of operating under high pressure with significant solids content, characteristic of the output from `wholesale high head slurry pump` suppliers.

Diverse Application Scenarios and Industries Served

High-pressure slurry pumps are indispensable across a multitude of heavy industrial applications where abrasive, corrosive, or high-density slurries need to be transported efficiently. The versatility of solutions offered by china high pressure slurry pump manufacturers ensures they meet the unique demands of various sectors.

Key Industries and Typical Applications

-

Mining and Mineral Processing:

This is arguably the largest consumer of high-pressure slurry pumps. Applications include:

- Tailings disposal and beneficiation plants.

- Slurry pipeline transport from ore processing to storage.

- Hydraulic backfilling in underground mines.

- `High pressure gold dredge pump` operations for alluvial mining.

Advantage: Exceptional wear resistance from high-chrome alloy components ensures longevity in highly abrasive environments, minimizing costly downtime.

-

Metallurgy:

Handling slag, ash, and other by-products from smelting and refining processes.

- Iron and steel production: slag granulation and transfer.

- Aluminum smelting: red mud pumping.

Advantage: Robust construction to handle high temperatures and dense, abrasive slurries, ensuring consistent operation in demanding metallurgical plants.

-

Power Generation:

Primarily in coal-fired power plants for ash and FGD (Flue Gas Desulfurization) slurry handling.

- Bottom ash and fly ash transport.

- Lime slurry and gypsum slurry transfer in FGD systems.

Advantage: Corrosion resistance in acidic FGD slurries and high head capabilities for moving large volumes of ash over distances.

-

Chemical Processing:

Handling corrosive chemicals combined with abrasive solids.

- Transfer of catalyst slurries, acidic waste slurries, and other chemical suspensions.

- `High pressure pump for detergent slurry` and other viscous chemical mixtures.

Advantage: Specialized material linings (e.g., rubber, advanced polymers, stainless steel alloys) to withstand aggressive chemical attack while handling abrasive particles.

-

Water Supply & Drainage / Environmental Protection:

Dredging, wastewater treatment, and sludge dewatering.

- River and harbor dredging.

- Sludge transfer in municipal and industrial wastewater treatment plants.

- `High head submersible slurry pump` for sumps and deep pits.

Advantage: Reliable performance in intermittent and continuous operation, capable of handling varying sludge densities and debris, critical for environmental sustainability initiatives.

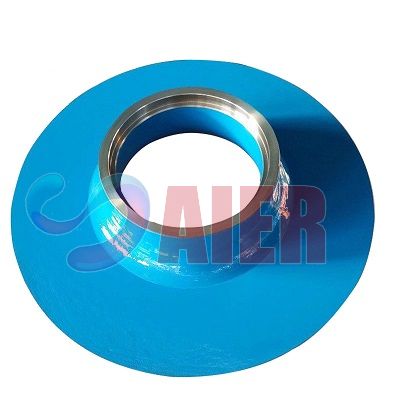

A high-performance pump component, demonstrating the quality standards of china high pressure slurry pump manufacturers.

The diverse range of applications underscores the necessity of choosing the right pump from reputable `china high head slurry pump manufacturers` based on specific slurry characteristics and operational demands.

Technical Advantages and Innovations from Chinese Manufacturers

Leading china high pressure slurry pump manufacturers distinguish themselves through continuous innovation, offering advanced technical features that translate into significant operational benefits for their clients. These advantages extend beyond mere performance to include aspects of sustainability and total cost of ownership.

Pioneering Design and Material Innovations

- Superior Wear Resistance: Through extensive metallurgical research, manufacturers have perfected high-chrome white iron alloys (e.g., A05, A07, A49) with microstructures optimized for extreme abrasion. These materials, used in impellers, volute liners, and throatbushes (like the G10083A05 high chrome throatbush), offer significantly longer service life than conventional materials, reducing replacement frequency and maintenance costs.

- Advanced Hydraulic Design: Sophisticated CFD (Computational Fluid Dynamics) simulations lead to optimized impeller and casing geometries. This results in smoother flow paths, minimized turbulence, reduced cavitation, and ultimately higher hydraulic efficiency, directly translating to `energy saving` in operations.

- Corrosion Resistance: For chemical and acidic slurries, manufacturers offer pumps with specialized rubber linings, advanced ceramic composites, or stainless steel alloys (Duplex, Super Duplex). This ensures exceptional `corrosion resistance`, crucial for the integrity and lifespan of `high quality chemical centrifugal slurry pump`.

- Robust Shaft and Bearing Assemblies: Designed for heavy-duty operation, these assemblies feature oversized shafts, robust bearings, and effective sealing arrangements (e.g., packed glands, mechanical seals) to prevent slurry ingress, ensuring pump reliability and extended service life even under high pressure.

- Modular Design for Ease of Maintenance: Many `china high pressure slurry pump` models feature modular wet-end designs, allowing for quick and easy replacement of wear parts. This significantly reduces maintenance time and associated labor costs, enhancing overall operational uptime.

- Energy Optimization: Beyond hydraulic efficiency, manufacturers integrate features like variable frequency drives (VFDs) and intelligent control systems to precisely match pump output to process demand, leading to substantial energy savings and reduced carbon footprint.

Comparative Performance Data: Wear Life

A key metric for slurry pump performance is the wear life of critical components. The table below illustrates the extended wear life achieved by high-chrome alloys compared to traditional materials in abrasive slurry applications, based on industry averages.

| Component Material | Typical Slurry | Average Wear Life (Hours) |

|---|---|---|

| Natural Rubber | Fine, high impact abrasive (e.g., sand) | 1,000 - 3,000 |

| White Iron (Standard) | Coarse, moderately abrasive (e.g., coal) | 1,500 - 4,000 |

| High-Chrome Alloy (A05) | Coarse, highly abrasive (e.g., hard rock) | 4,000 - 8,000+ |

| Ceramic Composites | Fine, extremely abrasive with chemical attack | 6,000 - 10,000+ |

These advantages underscore why `china high pressure slurry pump manufacturers` are increasingly chosen for projects demanding high reliability and efficiency.

Vendor Comparison and Selection Criteria

Selecting the right `china high pressure slurry pump manufacturers` is a critical decision that impacts long-term operational costs, reliability, and project success. While many manufacturers offer competitive products, key differentiators should guide the selection process.

Key Criteria for Evaluating Manufacturers

- Experience and Reputation: Look for manufacturers with a proven track record, extensive years in the industry, and a strong portfolio of successful installations in similar applications. Established `china high head slurry pump manufacturers` often have better R&D capabilities and quality control.

- Quality and Certifications: Verify adherence to international quality standards such as ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System). Product-specific certifications (e.g., CE, API) are also important, ensuring compliance and reliability.

- Material Expertise: A manufacturer's ability to offer a wide range of wear-resistant and corrosion-resistant materials, specifically tailored for your slurry, is crucial. Enquire about their metallurgical capabilities and component service life guarantees.

- Customization Capabilities: Not all applications fit standard pump designs. The ability to provide bespoke solutions, including specific hydraulic designs, material combinations, or mounting arrangements, can be a significant advantage.

- After-Sales Support and Spare Parts: Reliable `wholesale high head slurry pump` suppliers should offer comprehensive after-sales services, including technical support, maintenance, and readily available spare parts (e.g., the G10083A05 high chrome throatbush). A global service network is a strong indicator of trustworthiness.

- Energy Efficiency: Evaluate pump performance curves and guaranteed efficiency levels. High-efficiency pumps lead to substantial energy savings over their operational lifespan, reducing the total cost of ownership.

- Warranty and Guarantees: A strong warranty period and clear guarantees on performance and wear life demonstrate a manufacturer's confidence in their product quality.

Vendor Comparison Matrix (Illustrative)

This matrix provides a simplified overview of how different aspects might be compared when evaluating potential china high pressure slurry pump manufacturers.

| Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| Years in Slurry Pump Industry | 25+ | 15+ | 10+ |

| Certifications (ISO, CE, etc.) | ISO 9001, CE, API 610 (relevant models) | ISO 9001, CE | ISO 9001 |

| Material Range for Wear Parts | Extensive (A05, A07, A49, Rubbers, PU, SS) | Good (A05, Rubbers) | Standard (A05) |

| Customization Capability | High (Bespoke designs, materials) | Moderate (Some modifications) | Limited (Standard models) |

| After-Sales Support & Spares | Global network, comprehensive | Regional, good stock | Basic, local |

| Energy Efficiency | Excellent (High BEP, VFD integration) | Good (Solid designs) | Standard |

This comparative approach assists decision-makers in evaluating the overall value proposition of different china high pressure slurry pump manufacturers, ensuring a choice that aligns with long-term strategic and operational goals.

Customized Solutions for Unique Industrial Challenges

While standard slurry pumps address many common applications, specific industrial processes often present unique challenges that necessitate highly specialized or custom-engineered solutions. Leading china high pressure slurry pump manufacturers excel in providing such tailored systems.

The Value of Bespoke Slurry Pump Engineering

- Application-Specific Material Selection: For slurries with unusual chemical compositions or extreme abrasive properties, manufacturers can develop or source custom alloys or specialized linings. This might include high-nickel alloys for certain corrosive acids or advanced ceramic-polymer composites for unparalleled wear and chemical resistance.

- Optimized Hydraulic Design: When standard pump curves do not perfectly match required flow and head, engineers can re-design impellers or modify casing geometries to achieve optimal efficiency at specific duty points. This is particularly valuable for unique `high head centrifugal slurry pump` requirements.

- Seal Arrangement Customization: Depending on the slurry's characteristics (e.g., foaming, gas content, abrasiveness), specific sealing solutions can be engineered. Options include various mechanical seal types, expeller seals, or specialized packing arrangements, often with external flush systems to ensure zero leakage and extended seal life.

- Mounting and Drive Configuration: Tailored baseplates, special motor selections (e.g., explosion-proof, high-efficiency, or specific voltage/frequency requirements), and alternative drive arrangements (belt-driven, direct-coupled, vertical shaft for `high head submersible slurry pump`) can be integrated to fit existing plant layouts or specific operational constraints.

- Instrumentation and Control Integration: Custom solutions can include advanced sensor integration for real-time monitoring of vibration, temperature, pressure, and flow, along with integration into existing DCS (Distributed Control System) or SCADA (Supervisory Control and Data Acquisition) systems for enhanced automation and predictive maintenance capabilities.

- Enhanced Safety Features: For hazardous environments, manufacturers can incorporate additional safety features, such as specialized guarding, redundant monitoring systems, or materials certified for specific atmospheric conditions.

The ability of `china high pressure slurry pump manufacturers` to offer these bespoke solutions is a testament to their engineering depth and commitment to solving complex fluid handling challenges for their clients.

Real-World Application Case Studies

Demonstrating proven performance in the field is critical for establishing confidence in `china high pressure slurry pump manufacturers`. These case studies highlight successful deployments in challenging environments.

Case Study 1: Copper Mine Tailings Management

- Client: Major copper mining corporation in South America.

- Challenge: Transporting highly abrasive copper tailings (40% solids by weight) over a distance of 5 km to a disposal pond, requiring a high head of 70 meters. Existing pumps suffered from excessive wear and frequent breakdowns.

- Solution: A leading `china high pressure slurry pump manufacturers` provided a series of AH-type high-head slurry pumps, specifically engineered with A05 high-chrome alloy wet ends, including a custom G10083A05 high chrome throatbush for improved wear life. The pumps were also integrated with a VFD system for optimized energy consumption.

-

Results:

- Wear life of critical components increased by 150%, significantly reducing maintenance frequency.

- Energy consumption was reduced by 12% due to improved hydraulic efficiency and VFD control.

- Unscheduled downtime reduced by 80%, leading to a substantial increase in operational availability.

- Client Feedback: "The new pumps provided by our Chinese partner have been a game-changer for our tailings operation. The extended wear life and reduced energy costs have directly impacted our profitability and operational efficiency."

Case Study 2: Flue Gas Desulfurization (FGD) at a Thermal Power Plant

- Client: Large thermal power plant in Southeast Asia.

- Challenge: Pumping highly corrosive and abrasive gypsum slurry (pH 4-5, 25% solids) in the FGD system. Traditional pumps required frequent liner and impeller replacements due to combined chemical attack and abrasion.

- Solution: A specialist `china high pressure slurry pump` provider supplied pumps with custom-engineered rubber-lined casings and impellers made of a unique corrosion-resistant high-chrome alloy. The design focused on minimizing recirculation zones to further reduce wear.

-

Results:

- Service life of wear parts quadrupled compared to previous installations.

- Leakage issues around shaft seals were eliminated through the implementation of advanced mechanical seals.

- Overall operational stability of the FGD system significantly improved.

- Client Feedback: "The customized chemical slurry pumps have solved a long-standing maintenance headache. The combination of material expertise and hydraulic design offered by these `china high quality chemical centrifugal slurry pump` manufacturers was exactly what we needed."

These instances exemplify the practical benefits derived from partnering with experienced `china high pressure slurry pump manufacturers` who understand and can engineer solutions for real-world industrial complexities.

Ensuring Trust: Certifications, Warranty & Support

Trustworthiness and authoritativeness are paramount when selecting industrial equipment. Reputable china high pressure slurry pump manufacturers demonstrate these qualities through transparent operations, robust certifications, clear warranty policies, and responsive customer support.

Authoritative Certifications and Standards Adherence

- ISO 9001:2015 Certification: This internationally recognized standard for Quality Management Systems ensures that manufacturers consistently provide products and services that meet customer and regulatory requirements. It signifies a commitment to quality control throughout the entire production process.

- CE Marking: For pumps destined for the European market, CE marking indicates conformity with health, safety, and environmental protection standards.

- ANSI/HI Standards: Adherence to standards set by the Hydraulic Institute (HI) ensures that pump performance is measured and rated consistently and accurately.

- Material Test Certificates: Reputable suppliers provide comprehensive material test reports for critical components (e.g., impellers, casing, shafts, G10083A05 high chrome throatbush), detailing chemical composition and mechanical properties, directly supporting product quality claims.

- Partner Clients and Years of Service: A long history of successful collaborations with global industrial leaders and decades of operational experience further cement a manufacturer's authority and reliability in the market.

Lead Time, Warranty, and After-Sales Support

-

Lead Time and Fulfillment:

Standard lead times for high-pressure slurry pumps typically range from 4 to 12 weeks, depending on customization level and component availability. Manufacturers with efficient production lines and robust supply chain management can often offer expedited delivery options for critical projects. Clarity on fulfillment timelines and transparent communication throughout the order process are hallmarks of reliable `china high pressure slurry pump manufacturers`.

-

Warranty Commitments:

Standard warranties usually cover manufacturing defects for 12 to 18 months from installation or 24 months from shipment, whichever comes first. Premium manufacturers may offer extended warranties on specific wear parts or entire units, reflecting their confidence in product longevity.

-

Customer Support and Technical Service:

Comprehensive after-sales support is crucial. This includes:

- 24/7 technical hotline or online support.

- On-site commissioning, training, and troubleshooting by experienced engineers.

- Readily available spare parts inventory and efficient logistics for global delivery.

- Preventative maintenance programs and wear analysis services.

These assurances collectively build a foundation of trust, enabling clients to invest confidently in `china high pressure slurry pump` solutions for their critical operations.

Frequently Asked Questions (FAQ)

Q1: What types of slurries can china high pressure slurry pump manufacturers handle?

A1: These pumps are designed to handle a vast range of slurries, from abrasive (e.g., sand, mineral concentrates, ash) to corrosive (e.g., acidic chemical slurries, FGD gypsum) and high-density slurries (e.g., tailings, heavy sludge). Material selection (e.g., high-chrome alloy, rubber lining, stainless steel) is tailored to the specific slurry properties.

Q2: How do Chinese manufacturers ensure the `energy saving` aspect of their high-pressure slurry pumps?

A2: Manufacturers employ advanced hydraulic designs to maximize pump efficiency at the best efficiency point (BEP). They also integrate energy-efficient motors and often recommend Variable Frequency Drives (VFDs) to allow precise speed control, reducing power consumption significantly by matching pump output to actual process demands.

Q3: What are the typical service intervals for maintenance on a `china high pressure slurry pump`?

A3: Service intervals vary depending on the specific application, slurry characteristics, and operational hours. However, with high-quality components like the G10083A05 high chrome throatbush and robust designs, many pumps can operate for 4,000-8,000 hours between major wear component replacements. Routine checks (lubrication, seal condition) are recommended more frequently.

Q4: Are spare parts readily available from `china high head slurry pump manufacturers`?

A4: Reputable manufacturers maintain extensive inventories of standard spare parts and wear components. Many also have established global distribution networks to ensure timely delivery, minimizing downtime for their clients. It's advisable to discuss spare parts availability and lead times during the procurement process.

Q5: Can these pumps be customized for specific operating conditions?

A5: Absolutely. A key strength of leading `china high pressure slurry pump manufacturers` is their ability to offer customized solutions. This includes tailoring materials, hydraulic designs, sealing arrangements, and even full pump system integration to meet unique project requirements and challenging operational parameters.

Conclusion

The landscape of high-pressure slurry pump manufacturing in China is characterized by advanced engineering, robust material science, and a strong commitment to meeting diverse industrial demands. From meticulous manufacturing processes to innovative design and extensive customization capabilities, china high pressure slurry pump manufacturers are well-positioned to serve global industries facing the toughest challenges in slurry transportation. By prioritizing factors such as technical specifications, application-specific advantages like `energy saving` and `corrosion resistance`, comprehensive after-sales support, and adherence to international quality standards, businesses can confidently partner with these manufacturers to achieve optimal operational efficiency and long-term reliability.

The continuous evolution in pump technology and the strategic emphasis on quality and performance underscore China's pivotal role in supplying the world with high-performance slurry handling solutions.

References

- ISO 9906:2012 - Rotodynamic pumps - Hydraulic performance acceptance tests - Grades 1, 2 and 3.

- Hydraulic Institute (HI) Standards - ANSI/HI 1.1-1.6-2021, Centrifugal Pumps: General Guidelines for Pumps.

- Journal of Mining & Metallurgical Engineering, Vol. 45, Issue 2, pp. 120-135, "Advancements in Wear-Resistant Materials for Slurry Pumping."

- Chemical Engineering World, August 2023, "Selecting Corrosion-Resistant Pumps for Aggressive Slurries."

- World Coal Magazine, December 2022, "Energy Efficiency in Slurry Transport for Coal Preparation Plants."

-

Essential Guide to FGD Pump Supplies – Efficiency and Sustainability for Industrial Emission Controls

NewsNov.24,2025

-

Leading FGD Pump Manufacturers for Reliable Flue Gas Desulfurization Solutions

NewsNov.24,2025

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025