Oct . 16, 2025 11:45 Back to list

China High Pressure Slurry Pump Manufacturers - OEM & ISO

What to Look For When Sourcing from china high pressure slurry pump manufacturers

If you work around tailings lines or thickener underflow, you already know: a high-pressure slurry pump lives or dies by the wear parts. In fact, one small part—the throatbush—often decides whether a maintenance shutdown happens this quarter or next. I’ve walked more plants than I can count, and, to be honest, the winner is usually a careful mix of metallurgy, machining, and testing discipline.

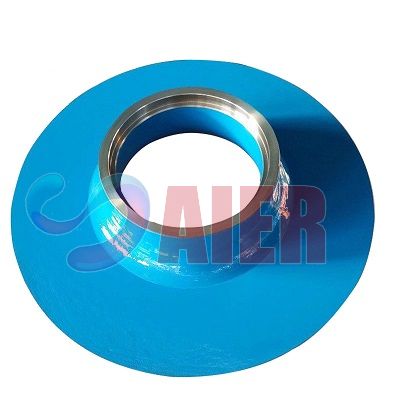

Product spotlight: G10083A05 high chrome throatbush

From China’s heavy-industry belt, the G10083A05 high chrome throatbush (Warman-compatible) keeps showing up in procurement shortlists. Origin: China. Material: high chrome white iron (≈27% Cr, A05-equivalent). It’s built for high head duties where discharge pressures and slurry velocities gnaw at clearances.

Key specifications (real-world use may vary)

| Item | G10083A05 high chrome throatbush |

| Material | High chrome white iron (A05, ASTM A532 Class III Type A) |

| Hardness | ≈HRC 58–65 (core), after heat treatment |

| Surface finish | Machined seating faces Ra ≈3.2–6.3 μm |

| Dimensional tolerance | ±0.25–0.5 mm typical (critical bores gauged) |

| Pressure envelope | For high-pressure slurry pump stages; check pump curve and casing rating |

| Wear test indicator | ASTM G65 Proc. A loss ≈ middling-low (lab data), application-dependent |

| Compatibility | Warman pump throatbush replacement (verify part code and seat) |

Process flow and quality checkpoints

- Alloy design: 26–28% Cr with controlled C, Mo, Ni balance for carbide network stability.

- Molding & casting: resin sand molds; riser/feeding simulation to minimize shrinkage.

- Heat treatment: austenitize, quench, temper; hardness mapping across 3–5 points per part.

- Machining: CNC boring of throat ID; fit-up gauges for pump frame alignment.

- Testing: UT where section permits, PT on seating faces; hardness per ASTM A370 methods; dimensional CMM sampling.

- Documentation: heat numbers, material certs (EN 10204 3.1), traceability retained ≥5 years.

Service life? It varies. In iron ore tailings at 40–55% solids, we’ve seen 1.2–1.6× the life versus basic white iron; in FGD limestone slurry (pH ≈5–6), more like parity unless you switch to duplex throatbush or rubber—depends on velocity. Many customers say throttling less and keeping the pump on the best-efficiency island helped more than metallurgy tweaks, surprisingly.

Where it’s used

Mining tailings, cyclone feed, dredging booster stations, alumina red mud, coal prep, sand and aggregate, and occasionally chemical slurries (check corrosion risk). If you’re shortlisting china high pressure slurry pump manufacturers, ask for abrasion test data and a couple of field references—not just pretty brochures.

Vendor snapshot (comparative, indicative)

| Manufacturer | Core strength | Certifications | Lead time | Customization | Price level |

|---|---|---|---|---|---|

| Aier Pumps (China) | High-chrome wear parts; Warman-compatible tooling | ISO 9001; EN 10204 3.1 MTRs | ≈3–6 weeks | A05/A49/R55; minor geometry tweaks | Mid |

| Vendor B (OEM aggregator) | Broad catalog; logistics | ISO 9001; occasional API-compliant processes | ≈6–10 weeks | Standard materials | Mid–High |

| Vendor C (local foundry) | Fast turns, small batches | Factory QA only | ≈2–4 weeks | Limited | Low |

Customization tips

- Metallurgy: A05 for abrasion, A49 for corrosion-abrasion; rubber or ceramic liner in acidic fines.

- Geometry: throat diameter match to impeller eye; tweak clearances for viscosity/solids.

- QC extras: request ASTM G65 data, microstructure photos, and hardness maps per heat.

Two brief field notes

Iron ore site (cyclone feed, 3500–4200 gpm): switching to G10083A05 extended throatbush life ≈18% (from 10 to 11.8 weeks), with no cavitation penalty. A dredging booster reported ~12% less washout at the cutwater after pairing high-chrome throatbush with a balanced impeller—small change, decent payoff.

Bottom line: when reviewing china high pressure slurry pump manufacturers, press for proof—chemistry certs, hardness, and at least one site reference under comparable solids loading. It seems that the credible suppliers don’t flinch at those asks.

Author’s note: I guess it’s not glamorous, but the throatbush is where a lot of budget disappears. Get the metallurgy and fit right, and everything else gets easier.

Authoritative citations

- ASTM A532 – Standard Specification for Abrasion-Resistant Cast Irons; ASTM G65 – Dry Sand/Rubber Wheel Abrasion Test.

- ISO 9001 – Quality Management Systems; EN 10204 – Metallic products: Types of inspection documents (3.1).

- GB/T 8263 – High Chromium White Cast Iron (China National Standard); ISO 21940-11 – Rotordynamics and balancing (for rotating assemblies).

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025