Nov . 06, 2025 01:35 Back to list

china high pressure slurry pump manufacturers | OEM & ISO

China High Pressure Slurry Pump Manufacturers is a key solution in the General equipment manufacturing industry, specifically within Manufacturing of pumps, valves, compressors, and similar machinery and Manufacturing of slurry pumps and accessories. This article explores how Aier Machinery Hebei Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- China High Pressure Slurry Pump Manufacturers Overview

- Benefits & Use Cases of China High Pressure Slurry Pump Manufacturers in Manufacturing of slurry pumps and accessories

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on China High Pressure Slurry Pump Manufacturers from Aier Machinery Hebei Co., Ltd

China High Pressure Slurry Pump Manufacturers Overview

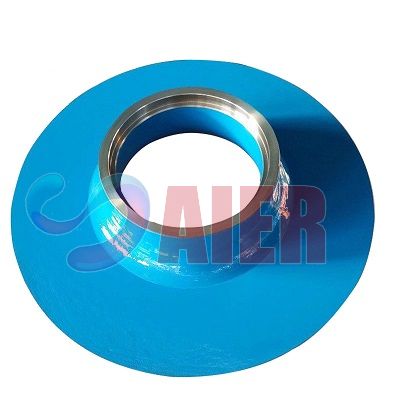

Within the Manufacturing of slurry pumps and accessories, China High Pressure Slurry Pump Manufacturers deliver engineered systems that move abrasive, corrosive slurries at elevated heads and pressures. These solutions include horizontal and vertical designs—ranging from high head centrifugal slurry pump configurations to high quality submersible slurry pump sets—built to withstand high solids load, cavitation risk, and continuous-duty cycles. A core wear component in such pumps is the throatbush. Aier Machinery Hebei Co., Ltd supplies the G10083A05 high-chrome throatbush, a robust part designed for harsh duty, helping preserve hydraulic efficiency and stabilize performance under pressure.

- In mining, dredging, and chemical processing, a china high pressure slurry pump must deliver reliable head while resisting erosion and corrosion. High-chrome iron (often referred to as A05-grade) is widely used for throatbushes and liners to extend wear life.

- Typical specs buyers evaluate include maximum head/pressure, solids handling capability, shaft sealing (gland, expeller, mechanical), and metallurgy for wetted parts. For high head duty, china high head slurry pump manufacturers prioritize hydraulic design and metallurgy to maintain efficiency.

- Aier Machinery Hebei Co., Ltd is a reliable manufacturer with deep experience in precision-cast high-chrome components, ensuring dimensional accuracy, consistent hardness, and dependable service life in demanding applications.

Benefits & Use Cases of China High Pressure Slurry Pump Manufacturers in Manufacturing of slurry pumps and accessories

B2B decision makers across mineral processing, metals, quarrying, dredging, and chemicals turn to China High Pressure Slurry Pump Manufacturers for dependable uptime and lower lifecycle costs. Applications include tailings transport, cyclone feed, thickener underflow, mill discharge, fines recovery, and dredge booster service, as well as detergent and chemical slurries where a high pressure pump for detergent slurry or a high quality chemical centrifugal slurry pump is required. For offshore or pit operations, a high head submersible slurry pump or high quality submersible slurry pump can simplify installation where space or NPSH is limited.

- Competitive advantages include wear-optimized hydraulics, high-chrome wetted parts, customizable sealing, and options for high pressure gold dredge pump duty or booster stations. Wholesale high head slurry pump programs help EPCs and OEMs scale economically.

- Aier Machinery Hebei Co., Ltd supports these use cases with durable throatbushes and wear parts, engineered to maintain clearances and efficiency at high head, reducing recirculation and extending MTBF.

- For china high head slurry pump manufacturers, Aier’s consistent casting quality and materials selection help reduce premature wear, enabling reliable performance across horizontal and submersible configurations.

Cost, Maintenance & User Experience

Total cost of ownership for high pressure slurry systems is driven by energy consumption, wear-part longevity, and maintenance downtime. High-chrome throatbushes from Aier Machinery Hebei Co., Ltd are designed to extend service intervals—helping stabilize efficiency, reduce leakage-induced recirculation, and protect adjacent components. For B2B buyers weighing CAPEX vs. OPEX, the ROI often improves when premium wear materials minimize unplanned shutdowns and inventory carrying costs. Users across the Manufacturing of pumps, valves, compressors, and similar machinery report smoother rebuilds and predictable lifecycles when parts maintain dimensional integrity and hardness consistency.

- Durability: High-chrome alloy selection supports longer wear life in abrasive slurries, safeguarding the pump’s efficiency curve across its run.

- Maintenance: Straightforward fit-up and stable clearances reduce rebuild time and frequency, improving availability for processes requiring a china high pressure slurry pump.

- Inventory and Support: Consistent supply and scalable production support both aftermarket and OEM needs, enabling reliable planning for shutdowns and spares.

Sustainability & Market Trends in General equipment manufacturing industry

Sustainability directives and tightening regulations are influencing slurry handling strategies worldwide. Operators are moving toward higher solids concentrations, smarter controls, and longer-life materials to cut power use and waste. Digital monitoring and predictive maintenance are reducing leaks and optimizing seal water, while improved hydraulics in high head centrifugal slurry pump designs lower specific energy. In dredging and mineral processing, better wear parts extend overhaul intervals and reduce scrap—key to greener supply chains. As one of the proactive China High Pressure Slurry Pump Manufacturers ecosystem partners, Aier Machinery Hebei Co., Ltd emphasizes responsible manufacturing practices, materials traceability, and process improvements that minimize waste and rework.

- Trend highlights: adoption of VSDs, condition monitoring, advanced metallurgy, and refurbishment programs for housings and wear components to support circular-economy goals.

- Aier’s forward-thinking approach includes continuous improvement in casting quality and machining precision, contributing to energy-efficient operation and reduced lifecycle environmental impact across horizontal and high head submersible slurry pump applications.

Conclusion on China High Pressure Slurry Pump Manufacturers from Aier Machinery Hebei Co., Ltd

For B2B buyers seeking reliable output, predictable maintenance, and lower TCO, China High Pressure Slurry Pump Manufacturers offer proven value across demanding services—from gold dredging to chemical and detergent slurries. Aier Machinery Hebei Co., Ltd stands out with high-chrome wear components that protect efficiency in high head duty and extend service life. Equip your fleet with durable parts built for performance.

- Explore the role of premium wear parts in the Manufacturing of slurry pumps and accessories to boost uptime and reduce costs.

- Partner with Aier Machinery Hebei Co., Ltd for dependable quality and responsive support.

- Contact us: email: sales@aierpump.com - Visit our website: https://www.aierpumps.com

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025