Nov . 12, 2024 02:44 Back to list

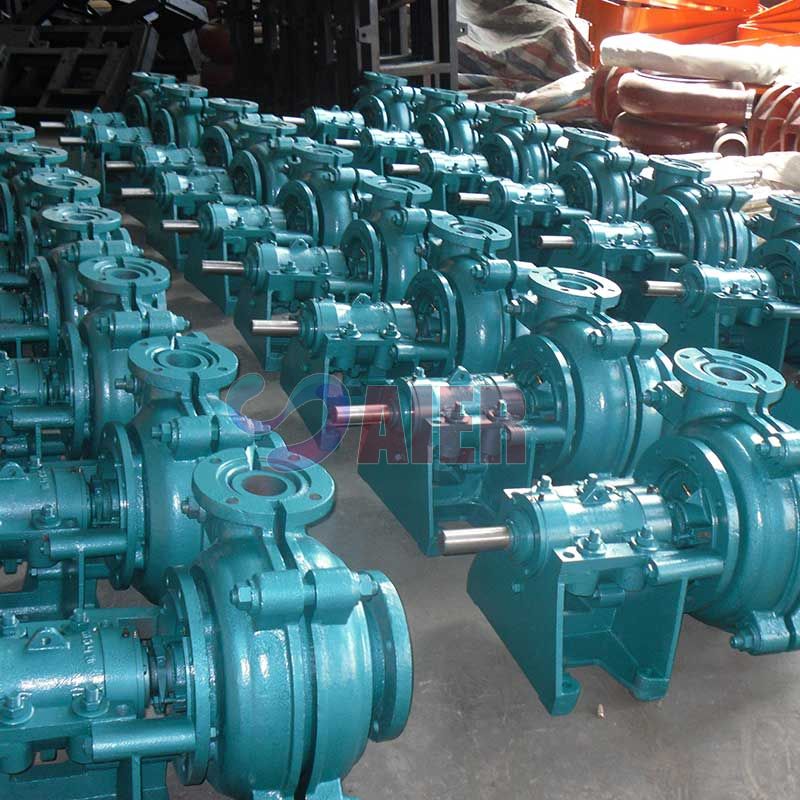

ceramic slurry pump manufacturer

Choosing the Right Ceramic Slurry Pump Manufacturer

Ceramic slurry pumps play a crucial role in various industries, particularly those involved in manufacturing processes that require the transport of abrasive and corrosive materials. Selecting the right ceramic slurry pump manufacturer is essential to ensure efficiency, durability, and cost-effectiveness in your operations. This article explores the key factors to consider when choosing a ceramic slurry pump manufacturer, the advantages of ceramic slurry pumps, and leading manufacturers in the industry.

Understanding Ceramic Slurry Pumps

Ceramic slurry pumps are designed specifically to handle slurries that consist of solid particles suspended in a liquid. These pumps are typically used in industries such as mining, ceramics, wastewater treatment, and chemical processing. The use of ceramic materials in the construction of these pumps provides significant advantages, including high wear resistance, corrosion resistance, and the ability to operate in harsh conditions.

Advantages of Ceramic Slurry Pumps

1. Durability One of the primary benefits of ceramic slurry pumps is their exceptional durability. The ceramic components can withstand extreme conditions and resist wear from abrasive materials, leading to longer operational life and reduced maintenance needs.

2. Corrosion Resistance Many industries involve corrosive substances that can damage traditional pump materials. Ceramic is inherently resistant to various chemicals, ensuring that the pumps maintain their integrity over time.

3. Efficiency Ceramic slurry pumps are designed to provide efficient flow rates with minimal energy consumption. This efficiency can lead to significant cost savings over time, making them a smart investment for many businesses.

4. Versatility These pumps can handle a wide range of slurries, including viscous and high-solid content mixtures. This versatility means that a single pump can often meet multiple operational needs, reducing the need for various pump types.

Factors to Consider When Choosing a Manufacturer

When selecting a ceramic slurry pump manufacturer, consider the following factors

ceramic slurry pump manufacturer

1. Reputation and Experience Look for manufacturers with a solid reputation in the industry. Companies that have been in the market for several years are more likely to have refined their processes and products to meet customer needs.

2. Product Range A good manufacturer should offer a wide range of ceramic slurry pumps with various configurations and specifications. This assortment ensures that you can find a product that precisely fits your application.

3. Quality Assurance Investigate the quality control measures in place at the manufacturing facility. ISO certifications and compliance with industry standards are indicators of a commitment to quality.

4. Technical Support and Service Ensure that the manufacturer provides comprehensive technical support and maintenance services. A responsive customer service team can be invaluable in addressing any issues that arise with the pump.

5. Customization Options Depending on your specific needs, you may require pumps with custom features. Choose a manufacturer willing to collaborate with you to create a tailored solution.

6. Cost and Value While price is an important factor, it should not be the sole consideration. Evaluate the overall value of the product, including its longevity, efficiency, and performance. Sometimes a higher initial investment pays off in the long run through lower operational costs.

Notable Ceramic Slurry Pump Manufacturers

Several companies are recognized for their excellence in manufacturing ceramic slurry pumps. Leading manufacturers include

- Weir Minerals Known for their innovative and durable slurry pump solutions across various industries, Weir Minerals has a strong presence globally. - Schurco Slurry This manufacturer specializes in producing high-quality slurry pumps that feature advanced ceramic materials, ensuring both performance and longevity. - KSB With a long history in fluid handling, KSB offers a range of slurry pump products that are engineered for the most challenging applications.

Conclusion

Choosing the right ceramic slurry pump manufacturer is a critical decision that can significantly impact your operational efficiency and bottom line. By considering the above factors and understanding the advantages of ceramic slurry pumps, you can make an informed choice that meets your specific needs. Investing in quality products and a reputable manufacturer will pay dividends in performance, reducing downtime and enhancing productivity in your operations.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025