Oct . 12, 2024 03:23 Back to list

Top Manufacturers of Centrifugal Slurry Pump Liners for Optimal Performance and Durability

The Importance of Choosing Quality Centrifugal Slurry Pump Liners

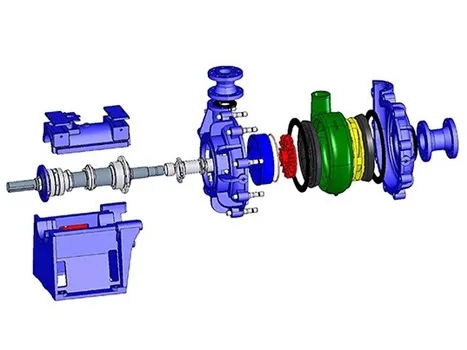

Centrifugal slurry pumps play a crucial role in the transportation of abrasive, viscous slurries in various industrial applications, including mining, mineral processing, and wastewater management. One of the key components of these pumps is their liners, which protect the pump casing from erosion and wear caused by the abrasive nature of the materials being transported. Selecting the right manufacturers for centrifugal slurry pump liners is vital to ensure efficiency and longevity in pump performance.

Understanding Slurry Pump Liners

Slurry pump liners serve as a protective barrier between the pump casing and the abrasive slurries. They are designed to withstand harsh environments, high pressures, and the wear and tear associated with transporting solid-laden liquids. Typically made from high-quality materials such as rubber, urethane, or metal alloys, these liners must be able to endure chemical corrosion, high temperatures, and mechanical stresses.

Factors to Consider When Choosing Manufacturers

1. Material Quality The quality of the materials used in the manufacturing of pump liners significantly affects their performance and lifespan. Reputable manufacturers employ advanced materials that offer superior resistance to abrasion and corrosion, ensuring that the liner can handle harsh industrial conditions.

2. Manufacturing Standards It is essential to choose manufacturers that adhere to internationally recognized quality standards, such as ISO 9001. These certifications guarantee that the production processes are consistently monitored and that the products meet or exceed industry benchmarks.

centrifugal slurry pump liner manufacturers

3. Customization Options Different applications may require specific liner designs and materials. Leading manufacturers offer customization options to meet the unique requirements of various industries. This could include customizing the thickness of the liner, the type of rubber or metallic alloy used, and tailoring the design to fit specific pump models.

4. Research and Development Manufacturers that invest in research and development often lead the market with innovative solutions. These companies are more likely to use cutting-edge technologies and methodologies to improve their products’ durability and efficiency, leading to reduced downtime and maintenance costs for their customers.

5. Technical Support and Service The relationship between pump manufacturers and their clients extends beyond the point of purchase. Excellent customer service, including technical support, maintenance guidance, and timely delivery of spare parts, can significantly affect the overall operational efficiency of slurry pumps. Opting for manufacturers known for strong customer support can lead to smoother operations and fewer unexpected disruptions.

6. Reputation and Experience Established manufacturers with a solid reputation in the industry are more likely to produce reliable and durable products. Researching customer reviews, case studies, and testimonials can provide insights into a manufacturer’s past performance and product reliability.

7. Cost Efficiency While cost should not be the sole factor in your decision-making process, it is essential to consider the long-term value. High-quality liners may come at a premium price, but their durability and efficiency can lead to significant cost savings over time through reduced maintenance and replacement needs.

Conclusion

Choosing the right manufacturer for centrifugal slurry pump liners is a critical component in enhancing the lifespan and efficiency of slurry pumps in industrial applications. By focusing on material quality, manufacturing standards, customization, R&D investment, technical support, and the manufacturer’s reputation, businesses can ensure they make informed decisions. Investing in high-quality pump liners from reputable manufacturers ultimately leads to improved performance, reduced operational costs, and increased productivity in handling abrasive slurries. As industries continue to evolve and demand higher efficiency and durability, the importance of selecting the right slurry pump liner manufacturers cannot be overstated.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025