Oct . 10, 2024 02:31 Back to list

Centrifugal Slurry Pump Replacement Parts Manufacturing Solutions for Efficient Operations

Understanding Centrifugal Slurry Pump Spare Parts

Centrifugal slurry pumps play a crucial role in the transport of abrasive and viscous materials across various industries such as mining, chemical processing, and wastewater management. The robust design of these pumps enables them to handle demanding conditions, particularly in environments where conventional pumps may falter. However, like any piece of heavy machinery, they require maintenance and replacement parts to ensure optimal performance. This is where the factory for centrifugal slurry pump spare parts becomes essential.

Importance of Spare Parts

Spare parts in centrifugal slurry pumps can significantly impact the overall efficiency and longevity of the pumping system. Components such as impellers, liners, seals, and bearings must be made from durable materials capable of resisting wear and tear caused by the challenging materials being pumped. Choosing high-quality spare parts not only minimizes downtime but also enhances the reliability of operations, ultimately resulting in cost savings for companies.

Key Components of Centrifugal Slurry Pumps

1. Impellers The impeller is the heart of a centrifugal slurry pump. It transfers energy from the motor to the fluid, propelling the slurry through the system. Impellers can be made from materials like high-chrome alloy or rubber, depending on the nature of the slurry and its abrasive characteristics. Regular inspection and timely replacement of impellers are vital to maintaining efficient flow rates.

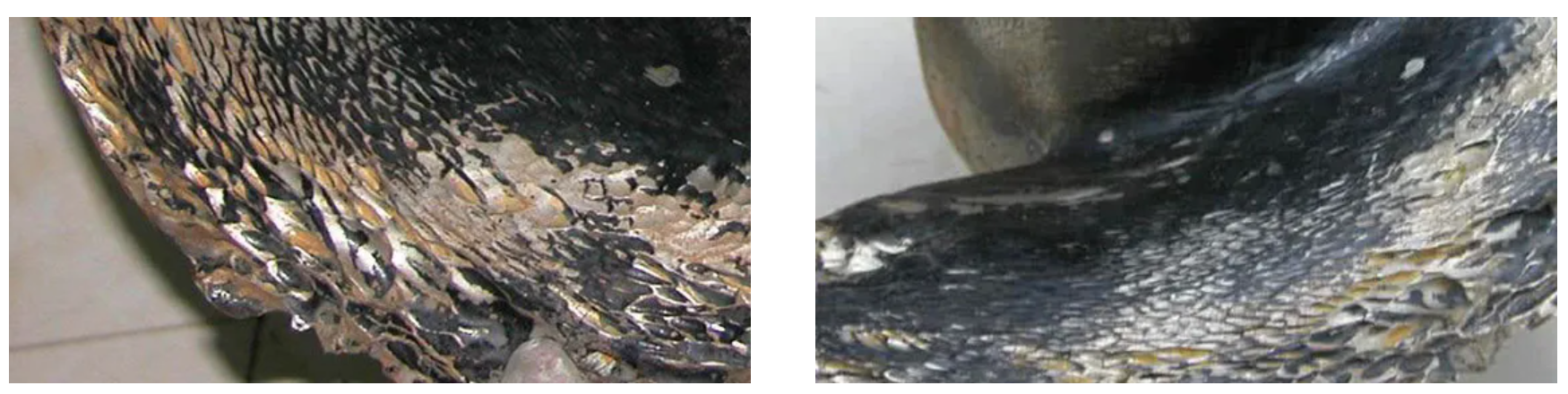

2. Pump Liners These components are critical in providing a protective barrier within the pump, safeguarding against abrasive damage. Liners generally undergo significant wear from the abrasive particles in the slurry, making the use of high-quality materials crucial. The choice between metal and rubber liners depends on the specific application requirements and slurry characteristics.

centrifual slurry pump spare parts factory

3. Seals and Gaskets To prevent leaks and maintain pressure, high-quality seals and gaskets are essential. Failing seals can lead to material loss and reduced efficiency. In a slurry pump, where abrasive materials are in play, seals made of suitable compounds can prolong the lifespan of the pump and reduce maintenance costs.

4. Bearings Bearings support the rotating components of a pump and ensure smooth operation. In a slurry pump, bearings are subject to harsh conditions due to the environment. Using durable bearings designed for high loads and extreme conditions will enhance the reliability of the pump.

Choosing the Right Spare Parts Manufacturer

Not all spare parts manufacturers are created equal. When selecting a factory for centrifugal slurry pump spare parts, companies should look for manufacturers with a proven track record in quality and service. Certification in industry standards, the availability of a wide range of components, and the capability of custom manufacturing to meet specific needs are just a few indicators of a reliable supplier.

Conclusion

The operational efficiency of centrifugal slurry pumps is significantly influenced by the quality of their spare parts. Investing in high-quality components from a reputable manufacturer can lead to increased pump reliability, reduced downtime, and ultimately substantial cost savings. As industries continue to rely on centrifugal slurry pumps for their processes, ensuring a steady supply of high-quality spare parts will remain a top priority for companies seeking to enhance their operational efficiency and productivity.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025