Jan . 13, 2025 14:54 Back to list

C23 Stainless Steel, A05 High Chrome expellers

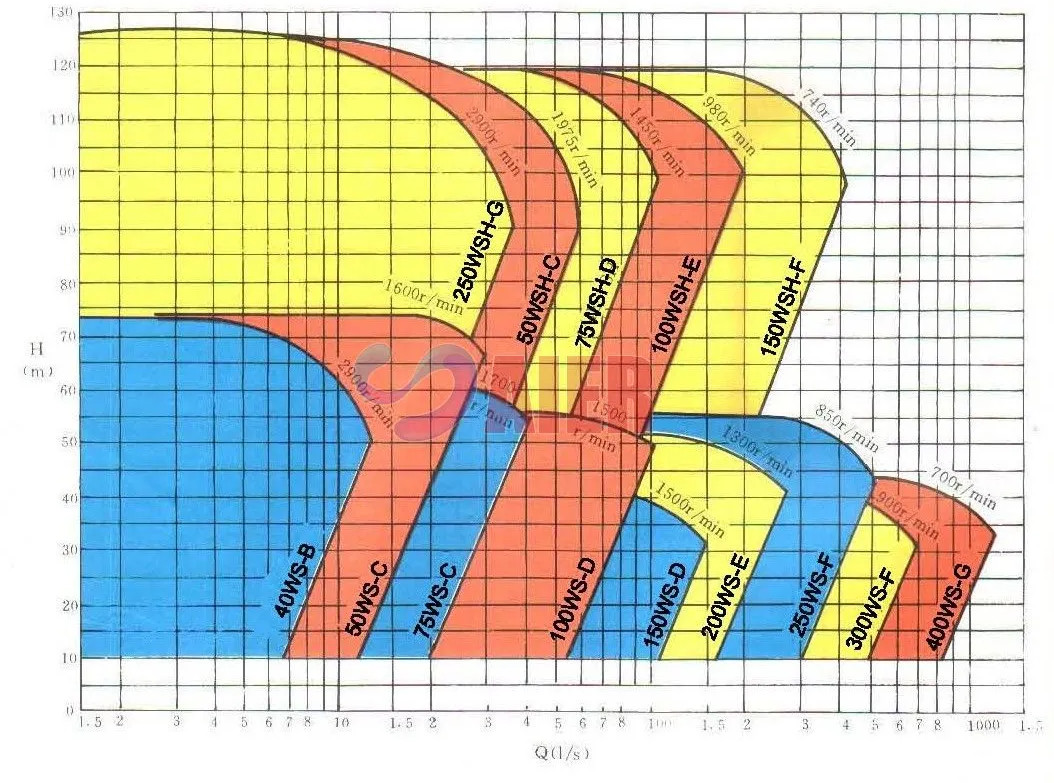

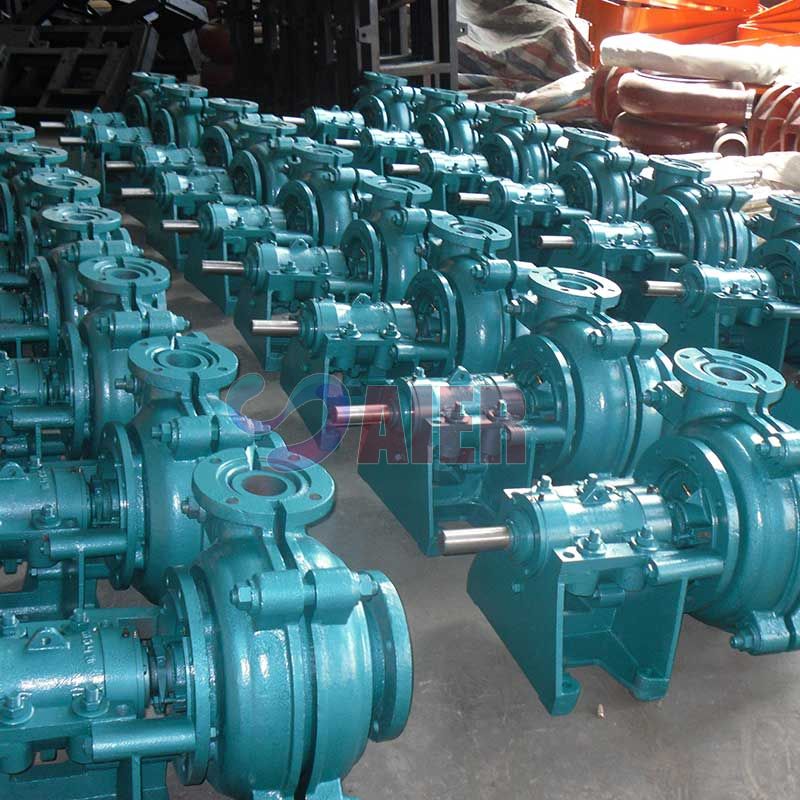

Choosing the right high head slurry pump is critical for any operation dealing with abrasive and viscous materials. Built to handle the rigorous demands of various industries—from mining to wastewater management—these pumps are specifically designed to move large volumes of thick, solid-laden fluids with ease and precision.

Trustworthiness is another critical factor to consider. Reliable manufacturers offer warranties and after-sales support, underlining their confidence in their products. They often provide flexibility with their solutions, offering customizable pump configurations tailored to meet specific industrial requirements. This level of service guarantees that clients can trust that their unique needs will be met with competence and care. Real-world experience also highlights the importance of routine maintenance checks. Many users note a substantial improvement in operational efficiency and lifespan when incorporating regular maintenance protocols. Companies that commit to ongoing training for their staff in pump operation and maintenance also report fewer failures and downtime instances. Industry-based anecdotal insights and evidence-based guidance clearly show that investing in a high-quality, high head slurry pump is a strategic decision. The combination of robust engineering, expert consultation, and adherence to maintenance best practices ensures these pumps deliver consistent and reliable performance, contributing significantly to the overall success and efficiency of any operation handling challenging slurry materials. In conclusion, a comprehensive understanding of these aspects not only ensures optimal selection and utilization of high head slurry pumps but also aligns with the broader goals of sustained operational efficiency and cost-effectiveness.

Trustworthiness is another critical factor to consider. Reliable manufacturers offer warranties and after-sales support, underlining their confidence in their products. They often provide flexibility with their solutions, offering customizable pump configurations tailored to meet specific industrial requirements. This level of service guarantees that clients can trust that their unique needs will be met with competence and care. Real-world experience also highlights the importance of routine maintenance checks. Many users note a substantial improvement in operational efficiency and lifespan when incorporating regular maintenance protocols. Companies that commit to ongoing training for their staff in pump operation and maintenance also report fewer failures and downtime instances. Industry-based anecdotal insights and evidence-based guidance clearly show that investing in a high-quality, high head slurry pump is a strategic decision. The combination of robust engineering, expert consultation, and adherence to maintenance best practices ensures these pumps deliver consistent and reliable performance, contributing significantly to the overall success and efficiency of any operation handling challenging slurry materials. In conclusion, a comprehensive understanding of these aspects not only ensures optimal selection and utilization of high head slurry pumps but also aligns with the broader goals of sustained operational efficiency and cost-effectiveness.

Latest news

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025