Oct . 08, 2025 22:35 Back to list

Best submersible well pump manufacturer—ISO, OEM—why us?

Inside a modern pump shop: choosing the right submersible partner (and why the WN dredge line matters)

If you’re hunting for a submersible well pump manufacturer, you’ll quickly notice the same three promises everywhere: efficiency, uptime, and honest lifecycle cost. In practice, only a few vendors back that up with real test data and tough metallurgy. I’ve walked a few factory floors; some are immaculate, some… less so. This one, in China, stuck with me because the team builds both deep-well submersibles and the WN dredge pumps (200WN–500WN) under one roof—useful, because heavy-duty dredge hydraulics tend to sharpen everyone’s game.

Industry trends, quickly

- High-efficiency hydraulics paired with VFDs and soft-starts—saves energy, reduces water hammer.

- Harder materials (high-chrome iron, duplex) to stretch wear life in abrasive wells and dredging.

- Condition monitoring—vibration, temperature, insulation checks—because surprises are pricey.

- Traceable QA: ISO 9001 systems, ISO 9906 performance tests; I always ask to see the curves.

Now, about the WN dredge family: 200WN to 500WN single-casing, single-stage, cantilevered, horizontal centrifugal pumps—two gearbox couplings (frame and pump box). Not submersible, true, but their abrasive-duty heritage overlaps with well pumps in bearings, sealing logic, and, frankly, in the company’s machining discipline. That matters when you’re picking a submersible well pump manufacturer.

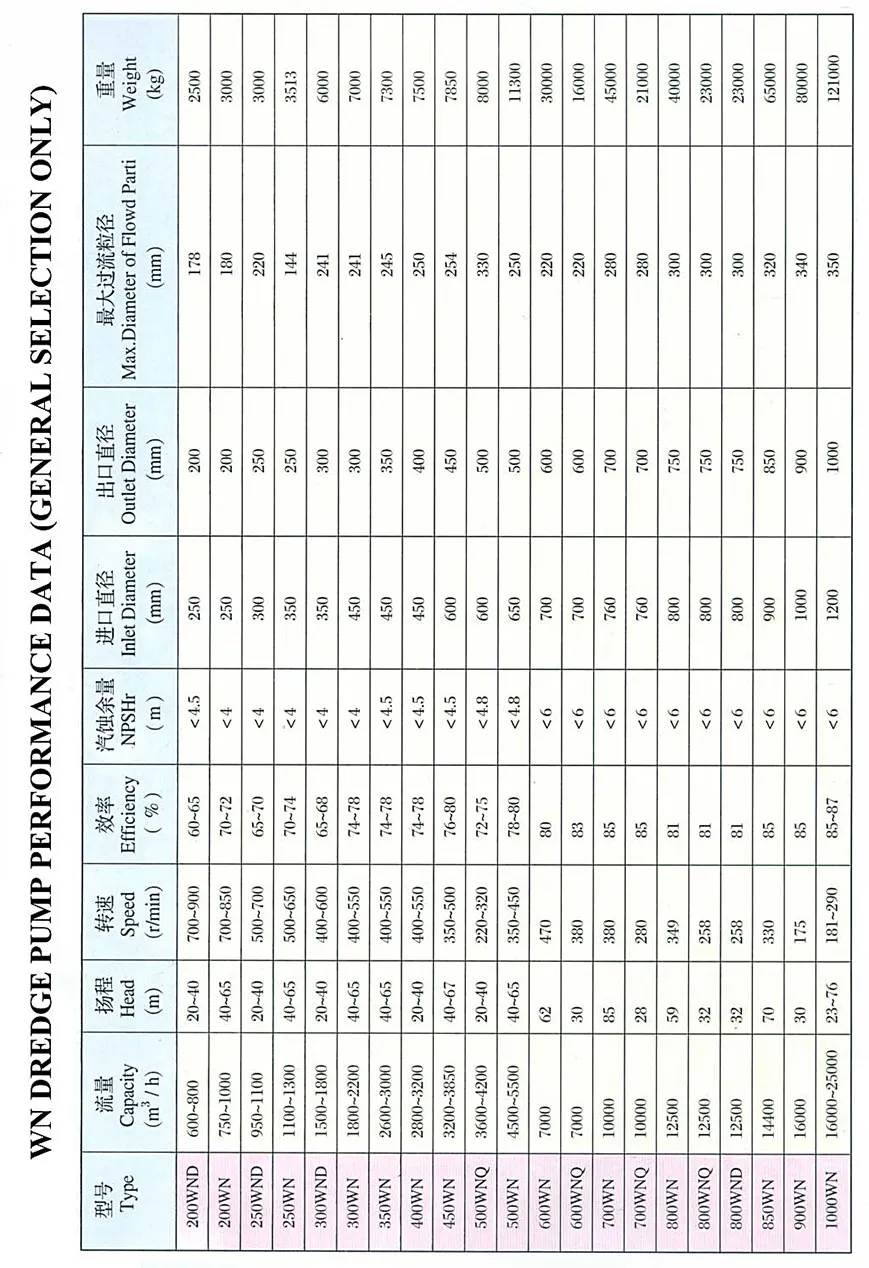

Typical specs (WN Dredge Pump, China origin)

| Models | 200WN–500WN | Casing/Stage | Single casing, single stage, horizontal, cantilevered |

| Flow | ≈ 800–6000 m³/h (real-world may vary) | Head | ≈ 25–85 m |

| Solids handling | Up to 25–30% by volume, particle size up to ≈ 220 mm | Materials | High-chrome white iron (A05), optional duplex or rubber-lined parts |

| Drive coupling | Frame or pump-box with gearbox | Efficiency | ≈ 72–84% (ISO 9906 Grade 2B) |

| Testing | Hydro + performance per ISO 9906 / GB/T 3216 | Service life | Wear parts ≈ 2,000–4,000 hr in abrasive slurry |

For wells, the same shop offers multi-stage submersible bowls and motors; efficiency upticks of 3–6% with tighter tolerances aren’t unheard of, according to maintenance folks I trust. That’s why I rate them as a capable submersible well pump manufacturer.

Where it fits

- Municipal and agricultural wells needing stable drawdown, low NPSH, and VFD-ready motors.

- Mining/dewatering: high-sand content, variable levels, rugged seals.

- Dredging and reclamation (WN): long-duty cycles, big solids, gear-coupled reliability.

Process flow and QA

Materials selection (A05 high-chrome or duplex) → casting (lost-foam or resin sand) → heat treatment → CNC machining → dynamic balancing (ISO 1940) → assembly → hydrostatic test → performance test (ISO 9906/GB/T 3216) → paint and preservation. Certifications: ISO 9001 QMS, CE for machinery; motors can be built to IEC standards; API 610 methods referenced for good practice on rotating assembly checks. Test reports are archived—ask to see them; they’re usually proud to show curves.

Customization options

Impeller trims to hit BEP, seal choices (mechanical vs. packed), anti-corrosion coatings, flanges per ANSI/DIN, sensor packages (PT100, vibration), and gearbox ratios. For wells: cable length, thrust bearing options, and NEMA/IEC motor frames. A practical submersible well pump manufacturer meets you halfway on curves and lead times.

Vendor snapshot (fast take)

| Vendor | Origin | Strengths | Lead time | Certs | Notes |

|---|---|---|---|---|---|

| Aier Pumps (WN + submersible) | China | Abrasive-duty know-how, competitive pricing | ≈ 4–10 weeks | ISO 9001, CE | Factory testing per ISO 9906/GB/T 3216 |

| Global Brand A | EU | High efficiency, broad service network | ≈ 6–12 weeks | ISO/CE, optional ATEX | Premium pricing |

| Regional OEM B | APAC | Quick custom builds | ≈ 3–8 weeks | ISO 9001 | Check test rig capability |

Real projects (short and sweet)

- Southeast Asia sand mine: 350WN, slurry 18–22% vol; uptime improved ≈ 11%, liners at 2,700 hr.

- Municipal wells retrofit: submersibles with VFDs; energy down ≈ 9% YOY, fewer starts per day.

- Port reclamation: 500WN with pump-box coupling; throughput +15% with revised impeller trim.

Customer feedback? A bit blunt, honestly: “Don’t oversell; send the curves and let us judge.” Fair. When a submersible well pump manufacturer shows full test sheets, I’m inclined to trust them.

Citations

- ISO 9906: Rotodynamic pumps — Hydraulic performance acceptance tests.

- GB/T 3216: Rotodynamic pumps — Hydraulic performance acceptance tests (China).

- ISO 1940-1: Mechanical vibration — Balance quality requirements for rotors.

- EU Machinery Directive 2006/42/EC (CE conformity framework for machinery).

- API 610 (general good practice on centrifugal pump design and testing context).

-

Reliable FGD Pump Manufacturer China | Durable & Cost-effective Solutions

NewsNov.23,2025

-

Reliable fgd Pump Manufacturer Solutions for Emission Control | Aier Pumps

NewsNov.23,2025

-

Explore Advanced FGD Pump Factory Solutions for Cleaner Power Plants

NewsNov.22,2025

-

Reliable & Efficient FGD Pump Chinese Supplier for Cleaner Energy Solutions

NewsNov.22,2025

-

Reliable China FGD Pump Suppliers for Effective Flue Gas Desulfurization | AiEr Pumps

NewsNov.22,2025

-

China FGD Pump: Durable & Efficient Solutions for Emission Control

NewsNov.21,2025