Nov . 24, 2024 04:28 Back to list

ash slurry submersible pump suppliers

Understanding Ash Slurry Submersible Pumps and Their Suppliers

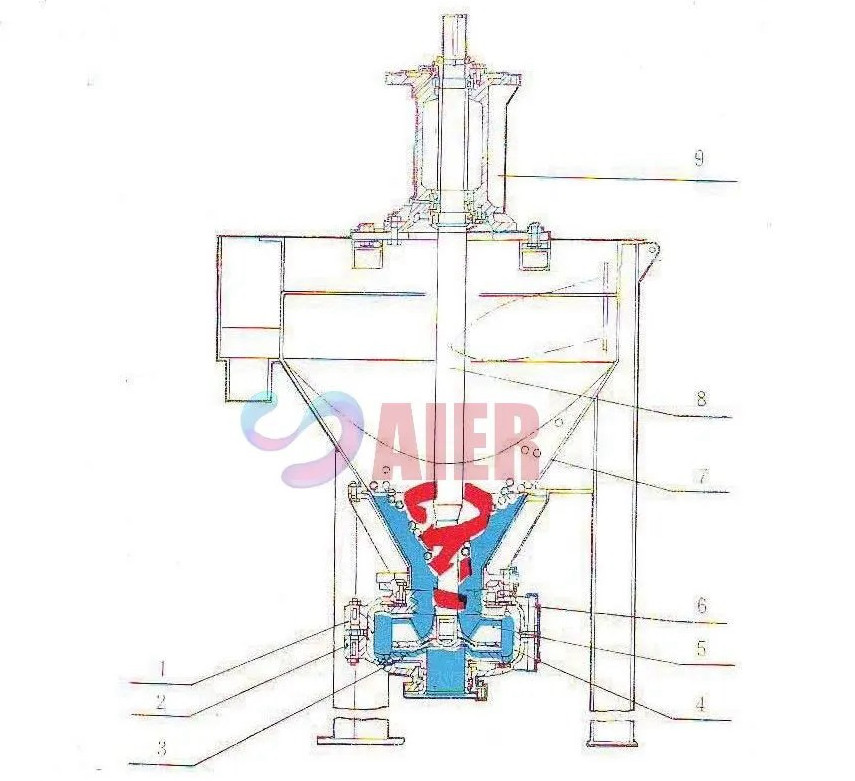

Ash slurry submersible pumps are critical components in various industrial applications, especially in power generation and waste management. These pumps are designed to handle abrasive and corrosive materials, making them ideal for transporting ash, sludge, and slurry resulting from coal combustion and other industrial processes. As industries strive for optimal efficiency and sustainability, the demand for specialized equipment, including submersible pumps, has grown significantly.

What Are Ash Slurry Submersible Pumps?

Ash slurry submersible pumps are specifically engineered to operate underwater, often found in ash ponds or other containment areas where sludge is present. Unlike standard pumps, submersible pumps are sealed and can be completely submerged in the liquid they are moving, which enables them to work without the need for priming. This unique feature not only helps to prevent issues associated with cavitation but also enhances their ability to manage heavy and viscous materials.

These pumps are constructed from durable materials, typically stainless steel or high-strength alloys, to withstand the harsh conditions of ash and slurry applications. The impellers are designed to minimize wear, ensuring longevity even when handling abrasive particles. Ash slurry submersible pumps are essential for maintaining operational efficiency and environmental compliance in industries where waste management is critical.

The Role of Suppliers

The effectiveness of ash slurry submersible pumps hinges significantly on the quality of the suppliers

. A reliable supplier will offer not just the pumps themselves but also comprehensive support services, including installation, maintenance, and repair. When selecting a supplier, it’s crucial to consider their experience in the industry, the range of products available, and their commitment to customer service.Key Factors to Consider When Choosing a Supplier

ash slurry submersible pump suppliers

1. Product Range Look for suppliers that offer a variety of pumps suited to different applications. This flexibility allows you to select the best pump for your specific needs.

2. Quality Assurance Choose suppliers who adhere to stringent quality control processes. Certifications and industry standards can be indicators of a reliable supplier.

3. Technical Support A good supplier should provide thorough technical assistance. This includes help with installation, troubleshooting, and maintenance guidance.

4. Customer Reviews Researching customer feedback can provide insight into the supplier's reputation and reliability. Testimonials and case studies are beneficial in assessing their capabilities.

5. Innovation The industry is constantly evolving, and suppliers who invest in research and development will often provide more advanced and efficient products.

Conclusion

In conclusion, ash slurry submersible pumps play a pivotal role in managing industrial waste effectively and sustainably. Selecting the right supplier is paramount to ensuring that you receive quality pumps that meet your operational requirements. By considering factors such as product range, quality assurance, technical support, customer reviews, and innovation, industries can make informed decisions that enhance efficiency and profitability. As companies continue to focus on sustainable practices, the importance of reliable ash slurry submersible pumps and their suppliers will undoubtedly grow, driving advancements in pump technology and applications.

-

Top China Submersible Slurry Pump Supplier Durable & Efficient Solutions

NewsMay.17,2025

-

Submersible Pump Spares Manufacturer High-Quality & Durable Components

NewsMay.17,2025

-

Vertical Centrifugal Sump Pump Supplier China Factory Solutions

NewsMay.16,2025

-

Vertical Spindle Slurry Pump Suppliers High-Quality China Manufacturers

NewsMay.16,2025

-

High-Quality Casting Submersible Pump Parts Manufacturer Durable Solutions

NewsMay.16,2025

-

Vertical Sump & Mud Screw Slurry Pump Company Durable Solutions

NewsMay.15,2025