Nov . 05, 2024 07:46 Back to list

8/6 rubber slurry pump manufacturers

Understanding 8/6% Rubber Slurry Pump Manufacturers

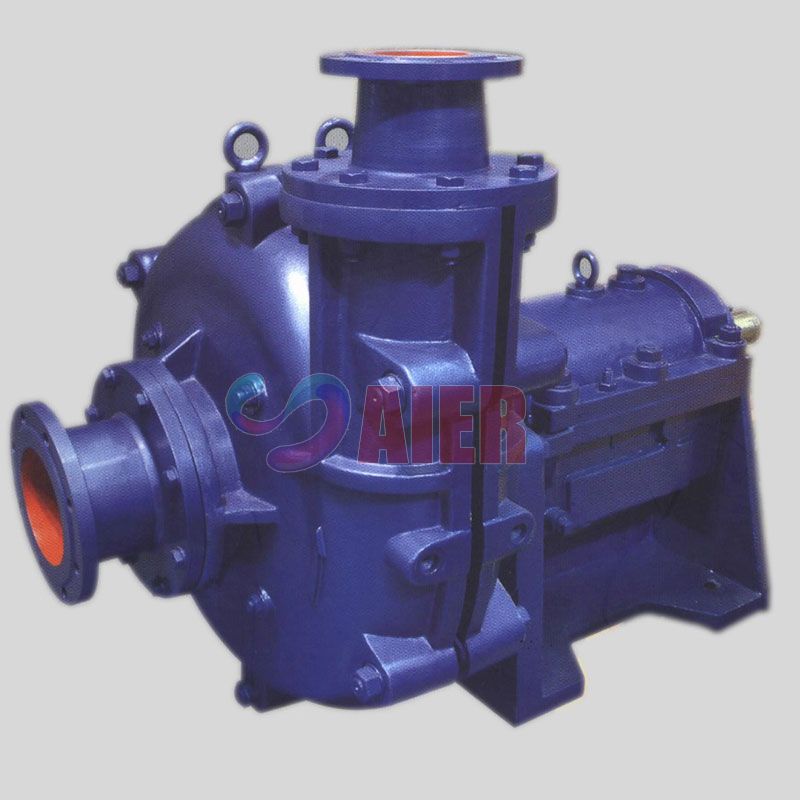

In the world of industrial pumping solutions, the 8/6% rubber slurry pump stands out as a reliable choice for transporting abrasive and viscous materials. This pump type primarily caters to industries such as mining, mineral processing, and construction, where the handling of slurry—composite mixtures of solids and liquids—is essential. Finding a reputable manufacturer of 8/6% rubber slurry pumps is crucial for ensuring the equipment's efficiency, durability, and overall performance. In this article, we'll explore what makes these pumps unique and what to consider when selecting a manufacturer.

What is an 8/6% Rubber Slurry Pump?

The designation 8/6% refers to the pump's size and capability. Specifically, the 8 indicates the nominal diameter of the pump's discharge outlet in inches, while the 6 corresponds to the inlet size. The percentage signifies that the pump is designed to handle a slurry with a consistency that can vary, but typically around 6% solid content. The use of rubber linings and components protects the pump from wear and tear, enhancing its lifespan while maintaining efficiency in transporting abrasive slurries.

The construction of the pump includes various high-quality materials, typically rubber, which helps to mitigate the risk of corrosion and erosion caused by abrasive materials. This makes rubber slurry pumps preferable for applications involving high percentages of solids, such as those found in mines and quarries.

The Importance of Choosing the Right Manufacturer

When investing in an 8/6% rubber slurry pump, partnering with the right manufacturer is crucial for a variety of reasons

1. Quality Assurance The quality of the materials and the design process significantly affect the pump's performance and lifespan. Reputable manufacturers use high-grade rubber and metals and adhere to strict quality control standards.

2. Customization Options Different industries may have unique needs based on the specific type of slurry being pumped. Leading manufacturers often offer customization options for sizes, materials, and configurations.

3. Technical Support A reliable manufacturer provides not only the equipment but also ongoing technical support. This support may include installation, maintenance, troubleshooting, and repairs, which are essential for smooth operations.

8/6 rubber slurry pump manufacturers

4. Warranty and Service Agreements It's important to discuss warranty options and service agreements. A robust warranty indicates confidence in the product, while a well-defined service agreement ensures that you receive timely assistance when needed.

5. Reputation and Experience Established manufacturers often have a track record of successful projects and satisfied customers. Researching a manufacturer’s reputation can save you potential headaches in the future.

Key Features to Look For

1. Durability Since rubber slurry pumps are subjected to harsh conditions, manufacturers should offer pumps with robust design features, including heavy-duty casings and wear-resistant components.

2. Efficiency Look for manufacturers who emphasize energy-efficient designs. Innovations that reduce operational costs are valuable in the long run.

3. Ease of Maintenance Pumps should be designed for easy access to internal components for maintenance. A design that simplifies this process can save significant time and costs.

4. Performance Ratings Performance metrics such as flow rate, head pressure, and power requirements should align with your specific needs. Manufacturers should provide clear specifications and performance ratings.

Conclusion

In conclusion, choosing the right manufacturer for an 8/6% rubber slurry pump is vital for operational success in industries that rely heavily on the transport of abrasive materials. By focusing on quality, service, and adaptability, businesses can ensure they invest in pumps that will not only perform reliably but also thrive in demanding environments. Doing thorough research on potential manufacturers, gathering customer feedback, and evaluating the key features will empower companies to make informed decisions that benefit their operational efficiency and bottom line. As industries evolve, so will the technology behind rubber slurry pumps, making it essential to stay informed about the latest advancements in this field.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025