Dec . 05, 2024 14:11 Back to list

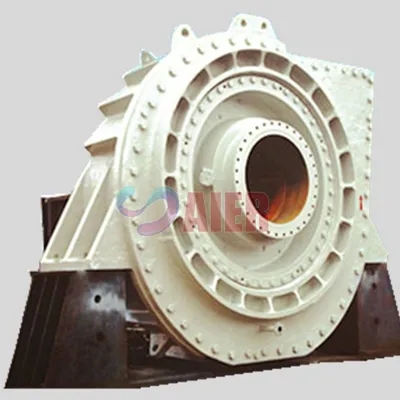

8/6 rubber slurry pump manufacturer

The Role of 8/6% Rubber Slurry Pumps in Modern Industries

In the realm of industrial processing, efficiency and durability are paramount. Among the various equipment utilized in these settings, pumps play a crucial role, particularly when it comes to handling abrasive and corrosive materials. One standout in this category is the 8/6% rubber slurry pump, which has gained recognition for its robust performance and reliability.

Understanding the 8/6% Rubber Slurry Pump

The designation 8/6% refers to the pump's dimension specifications; it typically indicates the size of the pump's inlet and outlet. The numbers represent the diameter in inches. The “rubber” in its name signifies the material composition of parts that are in contact with the slurry, which generally consists of suspended solid particles mixed with liquids. Rubber-lined slurry pumps are favored for their ability to resist wear and tear in harsh environments, making them suitable for mining, metallurgy, and other industries dealing with heavy slurries.

Advantages of Rubber Slurry Pumps

1. Enhanced Wear Resistance One of the most significant advantages of rubber slurry pumps is their high resistance to wear and abrasion. The rubber lining not only protects the pump from premature failure but also minimizes maintenance costs over time. This is particularly important in industries where pumps often face challenges from solid particles suspended in liquids.

2. Corrosion Resistance Many slurries can be chemically aggressive, posing a threat to traditional metal pumps. Rubber materials are inherently resistant to a range of chemicals, ensuring that these pumps can handle various types of slurries without degrading quickly.

3. Lightweight Construction Compared to metal pumps, rubber slurry pumps are often lighter. This characteristic can simplify installation and maneuverability, making them an excellent choice for facilities requiring frequent equipment repositioning.

4. Maintenance Ease The design of rubber slurry pumps often allows for easy maintenance and part replacement. Components can typically be replaced without the need for extensive disassembly, saving both time and labor costs.

5. Low Noise Operation Rubber materials can dampen vibrations, leading to quieter operation compared to traditional metal pumps. This can contribute to a better working environment, particularly in operations where noise levels are a concern.

8/6 rubber slurry pump manufacturer

Applications of 8/6% Rubber Slurry Pumps

8/6% rubber slurry pumps are used widely across several industries

- Mining These pumps are essential for transporting slurry from mineral processing facilities, where they handle materials like coal, copper, gold, and more. Their durability ensures they can cope with the harsh conditions often encountered in mining operations.

- Construction In construction projects, rubber slurry pumps are used to transport concrete and other mixtures, enabling efficient and consistent material supply.

- Wastewater Treatment In municipal and industrial wastewater treatment, these pumps facilitate the movement of sludge and other by-products, aiding in sewage processing and environmental protection.

- Chemical Processing Many chemical plants utilize rubber slurry pumps for mixing and transporting various corrosive substances. Their resistance to chemical wear ensures safe handling and prolonged operational life.

Selecting the Right Manufacturer

Choosing the right manufacturer of 8/6% rubber slurry pumps is crucial for ensuring reliability and performance. It's essential to look for manufacturers that adhere to industry standards and utilize high-quality materials. A reputable manufacturer should offer comprehensive technical support and warranties, as well as insights into the pump's performance in specific applications.

Conclusion

In conclusion, the 8/6% rubber slurry pump is an indispensable tool in modern industrial applications. Its wear and corrosion resistance, combined with easy maintenance and operational efficiency, make it a preferred choice for various sectors, including mining, construction, and wastewater treatment. As industries continue to evolve and demand more from their equipment, rubber slurry pumps are likely to play an even more critical role in ensuring productivity and reliability. Investing in high-quality pumps from reputable manufacturers is a step towards achieving operational excellence and sustainability in processing heavy and abrasive materials.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025