नोभ . 16, 2024 03:12 Back to list

vertical slurry sump pump factory

The Importance of Vertical Slurry Sump Pumps in Industrial Applications

In various industrial applications, especially in mining, construction, and wastewater management, the efficiency of fluid transport is paramount. Among the critical components that contribute to this efficiency are pumps, specifically vertical slurry sump pumps. These pumps are designed to handle abrasive slurries and are essential for maintaining smooth operations in environments where traditional pumps might struggle.

Understanding Vertical Slurry Sump Pumps

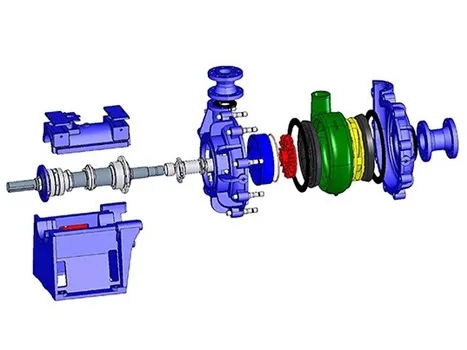

Vertical slurry sump pumps are submersible pumps that are typically installed in sumps or pits. Unlike standard centrifugal pumps that may have limitations when it comes to handling thick, viscous, or abrasive materials, these vertical pumps are designed to operate effectively under challenging conditions. The unique vertical orientation allows for direct installation in sumps, making them an ideal choice for applications that require the movement of large volumes of slurry.

Slurry, a mixture of solids and liquids, can vary greatly in its composition and viscosity. In mining operations, for example, slurry might consist of mineral ores combined with water. In wastewater treatment, the slurry could be comprised of organic and inorganic materials. The ability to pump such tough mixtures without clogging or damaging the pump is what makes vertical slurry sump pumps indispensable.

Key Features and Advantages

1. Durability One of the standout features of vertical slurry sump pumps is their construction. These pumps are typically made from high-strength materials like cast iron or stainless steel, which can withstand the abrasive nature of slurries. Their robust design extends the life of the pumps, thus reducing the need for frequent replacements.

2. Efficiency Vertical slurry sump pumps are designed to operate with high efficiency, even in difficult conditions. They often use a vortex impeller or other specially designed impellers that minimize wear and maintain a high flow rate, optimizing energy usage and reducing operational costs.

vertical slurry sump pump factory

3. Easy Maintenance The design of these pumps allows for easy access to parts that require regular maintenance or inspection. This feature is crucial in industrial settings where downtime can lead to significant productivity losses.

4. Versatility Whether for mining, construction, or municipal wastewater management, vertical slurry sump pumps can be adapted to various applications. Their capacity to handle different types of slurries makes them a versatile option for many industries.

5. Submersible Operation Being submersible, these pumps can operate deep within sumps, which helps to keep the surrounding area dryer and safer. This feature is particularly beneficial in mines and other environments where water accumulation can pose serious hazards.

Applications Across Industries

Vertical slurry sump pumps find applications in numerous industries. In the mining sector, they are used to manage water inflows and transport slurry from processing sites. In construction, they help in draining excavations and controlling groundwater. Additionally, in wastewater treatment facilities, these pumps assist in transporting sludge and other materials through the treatment process.

Conclusion

Investing in high-quality vertical slurry sump pumps is essential for industries that rely on the efficient transport of abrasive liquids. Their durability, efficiency, and versatility make them a crucial component in many operational processes. Factory production of these pumps has evolved significantly, with ongoing advancements in technology leading to improved designs and performance. When selecting a vertical slurry sump pump, industries should prioritize reputable manufacturers known for quality and reliability to ensure effective and long-lasting solutions for their pumping needs. By doing so, companies not only enhance their operational efficiency but also minimize downtime and reduce overall maintenance costs, paving the way for smoother and more productive industrial operations.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025