डिस . 10, 2024 12:28 Back to list

slurry pump wet end parts factory

Understanding the Importance of Slurry Pump Wet End Parts

When it comes to the efficient handling of abrasive and corrosive slurries in various industrial applications, slurry pumps play a critical role. At the heart of these pumps lies the wet end, which consists of components that come into direct contact with the pumped slurry. The quality, design, and durability of these wet end parts are crucial for the overall performance and longevity of the slurry pump.

What Are Slurry Pump Wet End Parts?

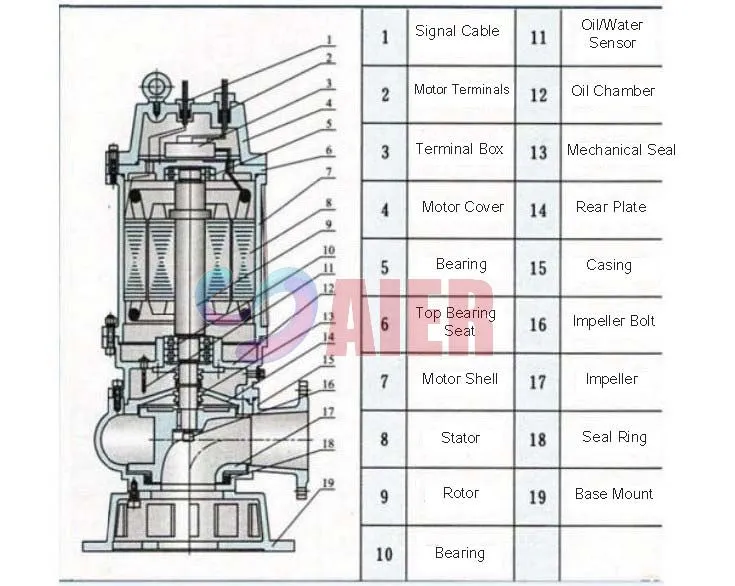

The wet end of a slurry pump typically includes several key components the pump casing, impeller, wear plates, liners, and the suction and discharge outlets. Each of these parts has a vital function in ensuring that the pump operates effectively and efficiently under varying conditions.

1. Pump Casing The pump casing houses the impeller and provides a pathway for the slurry to move from the suction side to the discharge side. This part must be made from materials that can withstand the abrasive nature of slurries, such as high-chrome alloys or rubber linings.

2. Impeller The impeller is the rotating component that imparts energy to the slurry, allowing it to flow through the pump. Its design and material must be selected based on the type of slurry being processed. For instance, a thicker, heavier impeller may be necessary for highly abrasive slurries.

3. Wear Plates and Liners These components protect the pump casing and impeller from wear caused by the abrasive nature of slurries. Regular inspection and replacement of wear plates and liners are essential to maintain pump efficiency, as worn parts can significantly reduce performance.

4. Suction and Discharge Outlets These parts are critical for the inflow and outflow of slurry. Their design must ensure optimal flow rates while minimizing the risk of blockages. Proper alignment and sealing are also necessary to prevent leaks.

The Role of Factory Manufacturing

To ensure the reliability and efficiency of slurry pump wet end parts, manufacturing processes must adhere to stringent quality standards. Factories specializing in slurry pump components typically utilize advanced technology and high-grade materials to produce parts that can withstand the challenges of industrial applications.

1. Material Selection The choice of materials is one of the most important factors in manufacturing slurry pump wet end parts. High-chrome iron, rubber, and polyurethane are common choices due to their excellent resistance to abrasion and corrosion.

slurry pump wet end parts factory

2. Precision Engineering The use of computer-aided design (CAD) and computer numerical control (CNC) machining enables manufacturers to achieve precise specifications for slurry pump components. This precision is crucial for ensuring parts fit correctly and perform optimally.

3. Quality Control Rigorous testing and quality control measures are implemented to ensure that slurry pump wet end parts meet industry standards. This includes testing for wear resistance, dimensional accuracy, and overall durability.

4. Custom Solutions Different industries and applications often have unique requirements. Reputable manufacturers offer custom solutions tailored to specific operational needs, thereby enhancing performance and longevity.

The Benefits of Investing in Quality Wet End Parts

Investing in high-quality slurry pump wet end parts offers numerous benefits, including

- Enhanced Performance Quality components lead to improved efficiency and reduced operational costs due to lower energy consumption and higher flow rates.

- Longevity and Reduced Downtime Durable materials and design reduce wear and tear, resulting in longer service life and minimizing the risk of pump failure.

- Reduced Maintenance Costs High-quality parts may require less frequent replacement and maintenance, allowing for significant cost savings over time.

- Increased Reliability Reliable pump performance translates to consistent operational output, which is crucial for industries such as mining, construction, and wastewater management.

Conclusion

In summary, the wet end parts of slurry pumps are fundamental to their performance, particularly in handling challenging slurries. Understanding the importance of materials, manufacturing processes, and the inherent value of investing in quality parts is vital for businesses relying on slurry pumps. As industries continue to evolve and demand increases, manufacturers must stay ahead by innovating and ensuring that their wet end parts stand up to the rigors of modern applications. Investing in the right slurry pump wet end parts will ultimately lead to improved efficiency, reduced operational costs, and increased productivity.

-

Electric Submersible Slurry Pump - Durable & Efficient China Suppliers

NewsMay.29,2025

-

Submersible Slurry Pump with Agitator Durable China Suppliers & Manufacturers

NewsMay.29,2025

-

Vertical Sump Pump Rubber Lined - Durable Corrosion-Resistant Design China Manufacturers

NewsMay.29,2025

-

High-Quality CH Warman Slurry Pump Factories Heavy Duty & Custom Solutions

NewsMay.28,2025

-

Wholesale Metal-Lined Slurry Pump Parts Durable & Corrosion-Resistant

NewsMay.28,2025

-

High-Efficiency Submerged Mining Vertical Slurry Pump Suppliers

NewsMay.28,2025