Nov . 14, 2024 15:23 Back to list

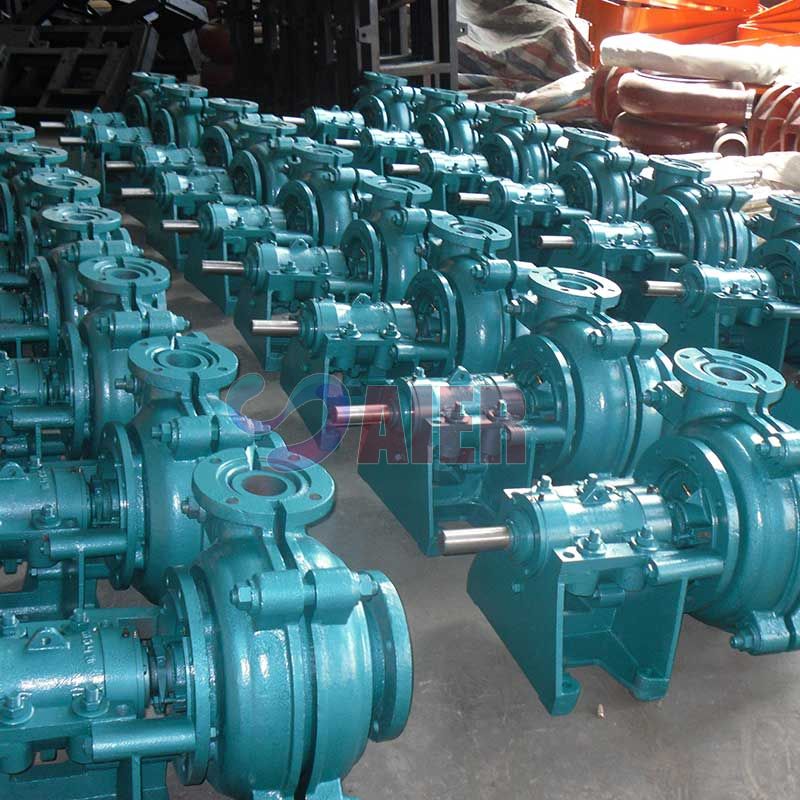

pump for lime slurry factory

The Importance of Efficient Pump Systems for Lime Slurry Factories

In the production of lime slurry, the efficient transportation of materials is vital to ensure optimal processing and quality control. Lime slurry, a mixture of lime (calcium hydroxide) and water, is widely used in various industries, including water treatment, mining, and construction. Given the vital role that lime slurry plays, having a reliable and efficient pump system is crucial for any lime slurry factory. This article delves into the importance of pump technology in lime slurry production and the factors to consider when selecting the right pump.

Understanding Lime Slurry

Lime slurry is typically created by slaking quicklime (calcium oxide) with water, resulting in a highly alkaline solution that can effectively neutralize acidity, remove impurities, and provide minerals. Its applications range from purifying water in treatment plants to stabilizing soil in construction projects. Due to its versatility, the market demand for lime slurry continues to rise, necessitating enhanced production techniques to keep up with consumption rates.

The Role of Pumps in Lime Slurry Production

Pumps are essential in the lime slurry production process, mainly for transporting the slurry from the mixing area to storage tanks or directly to applications. Given the thick and abrasive nature of lime slurry, the selection of an appropriate pump is paramount. Pumps must be able to handle the viscosity, solid content, and corrosive nature of the slurry without degradation of performance or efficiency.

Types of Pumps Used in Lime Slurry Factories

1. Centrifugal Pumps The most common type of pump used in lime slurry applications, centrifugal pumps work by converting rotational energy into hydrodynamic energy, moving the slurry through the system. When selecting a centrifugal pump, factors such as the specific gravity of the slurry, the required flow rate, and the pump's material compatibility with lime slurry must be considered.

2. Progressive Cavity Pumps These pumps are ideal for handling thick and viscous materials. They consist of a helical rotor that moves the slurry through a stator, making them suitable for low flow rates and high viscosity applications. Their design allows for smooth flow and minimal shear, which is essential in maintaining the integrity of the slurry.

pump for lime slurry factory

3. Diaphragm Pumps Known for their ability to handle corrosive and abrasive materials, diaphragm pumps provide a safe pumping solution for lime slurry. They can handle solid particles without clogging, making them a reliable choice in environments where other pumps might fail.

Factors to Consider in Pump Selection

When choosing a pump for lime slurry, several factors come into play

- Material Compatibility The pump must be constructed from materials that can withstand the corrosive effects of lime slurry. This often involves selecting stainless steel or specialized alloys that offer high resistance to wear and tear.

- Flow Rate and Viscosity Understanding the required flow rate of the lime slurry and its viscosity is crucial for selecting the right pump type and size. Each pump has its specific operating ranges, and exceeding these can result in pump failure or reduced efficiency.

- Maintenance Requirements Operational uptime is vital in a production environment. Thus, choosing a pump with lower maintenance needs can help decrease downtime and ensure continuous operation.

- Energy Efficiency With a focus on sustainability, selecting energy-efficient pumps can significantly reduce operational costs and the factory's carbon footprint.

Conclusion

In the dynamic world of lime slurry production, choosing the right pumping system is essential for efficient operations. By carefully considering the type of pump, material compatibility, and operational requirements, lime slurry factories can enhance productivity and ensure the quality of their products. As industries continue to innovate and expand, investing in efficient pump technologies will be key to meeting market demands and achieving sustainability goals. Consequently, the integration of advanced pump systems will not only drive profitability but also contribute to the environmental responsibility of lime slurry production processes.

-

Small Dredger and Marine Pontoon - Aier Machinery | Gold Mining Equipment, Industrial Dredging Systems

NewsAug.05,2025

-

Small Dredger and Marine Pontoon- Aier Machinery Hebei Co., Ltd|Cost-Effective Solutions&High-Efficiency Dredging

NewsAug.05,2025

-

Submersible Pump Impeller Manufacturer | GPT-4 Turbo Series

NewsAug.05,2025

-

Premium Warman Slurry Pump Mechanical Seal - Leak-Proof

NewsAug.04,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025