जानेवारी . 24, 2025 04:33 Back to list

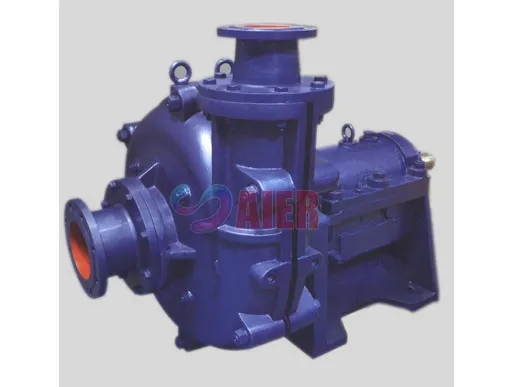

C23 Stainless Steel, A05 High Chrome expellers

Stainless steel submersible pumps have emerged as essential components across various industries, providing efficient solutions for handling water and other fluid substances. Their primary appeal lies in their construction and versatility, combining material durability with technological innovation. For those navigating the complexities of selecting the right pump, understanding the nuances of stainless steel submersible pumps can ensure long-term performance and reliability.

Expert users and those with extensive experience in pump selection often emphasize the importance of understanding the specific head and flow requirements before purchase. Calculating the total dynamic head, which includes both the vertical lift and friction losses in the system, is crucial for ensuring the pump operates efficiently under expected conditions. Furthermore, consulting with manufacturers or authorized distributors can provide insights into advanced features such as variable speed drives and smart sensors for real-time performance monitoring. Establishing trust in the technology often comes from field data and real-world applications. Case studies revealing the deployment of stainless steel submersible pumps in challenging conditions, such as mining sites or flood-prone regions, can offer valuable learning experiences. In these narratives, performance metrics such as flow rate stability, energy savings, and maintenance intervals paint a clearer picture of what prospective users can expect. Sector-specific insights underscore the adaptability of these pumps. For example, in agriculture, the use of stainless steel submersible pumps in drip irrigation systems can dramatically improve water distribution efficiency, conserving water resources while ensuring adequate plant hydration. In contrast, municipal applications may focus on the pump’s ability to handle variable demand without compromising on water pressure, catering to both peak usage times and off-peak periods. An authoritative stance on stainless steel submersible pumps is further supported by adherence to regulatory standards and certifications. These benchmarks ensure that the pumps meet safety, environmental, and performance criteria, which can vary by region or application. Trust is inherently tied to these certifications, offering peace of mind to users who rely on these pumps for critical operations. To summarize, stainless steel submersible pumps are not just an investment in durable, corrosion-resistant technology but also a pragmatic choice for efficiency-savvy industries. Their ability to thrive in diverse environmental conditions and operational requirements, combined with ongoing advances in pump technology, underscores their relevance and indispensable role in modern fluid management solutions. Navigating choices and specifications with informed understanding ensures users not only optimize their fluid handling capabilities but also contribute to sustainable and reliable system operations.

Expert users and those with extensive experience in pump selection often emphasize the importance of understanding the specific head and flow requirements before purchase. Calculating the total dynamic head, which includes both the vertical lift and friction losses in the system, is crucial for ensuring the pump operates efficiently under expected conditions. Furthermore, consulting with manufacturers or authorized distributors can provide insights into advanced features such as variable speed drives and smart sensors for real-time performance monitoring. Establishing trust in the technology often comes from field data and real-world applications. Case studies revealing the deployment of stainless steel submersible pumps in challenging conditions, such as mining sites or flood-prone regions, can offer valuable learning experiences. In these narratives, performance metrics such as flow rate stability, energy savings, and maintenance intervals paint a clearer picture of what prospective users can expect. Sector-specific insights underscore the adaptability of these pumps. For example, in agriculture, the use of stainless steel submersible pumps in drip irrigation systems can dramatically improve water distribution efficiency, conserving water resources while ensuring adequate plant hydration. In contrast, municipal applications may focus on the pump’s ability to handle variable demand without compromising on water pressure, catering to both peak usage times and off-peak periods. An authoritative stance on stainless steel submersible pumps is further supported by adherence to regulatory standards and certifications. These benchmarks ensure that the pumps meet safety, environmental, and performance criteria, which can vary by region or application. Trust is inherently tied to these certifications, offering peace of mind to users who rely on these pumps for critical operations. To summarize, stainless steel submersible pumps are not just an investment in durable, corrosion-resistant technology but also a pragmatic choice for efficiency-savvy industries. Their ability to thrive in diverse environmental conditions and operational requirements, combined with ongoing advances in pump technology, underscores their relevance and indispensable role in modern fluid management solutions. Navigating choices and specifications with informed understanding ensures users not only optimize their fluid handling capabilities but also contribute to sustainable and reliable system operations.

Latest news

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025