जानेवारी . 14, 2025 12:29 Back to list

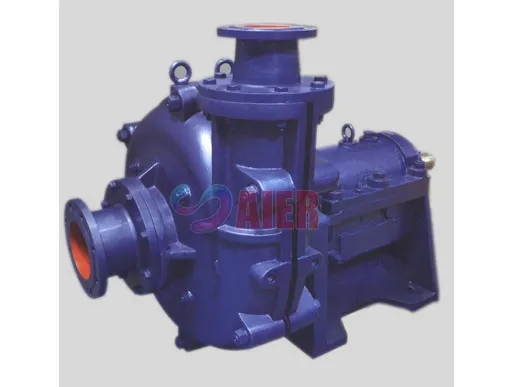

high head submersible slurry pump

Navigating the complex terrain of industrial applications, the high head submersible slurry pump stands as a pivotal tool for managing challenging tasks. These machines are engineered to handle abrasive, high-density slurries typically found in mining, construction, and waste management industries. Providing both substantial power and efficiency, high head submersible slurry pumps are indispensable for operations requiring continuous and reliable fluid transfer.

A cornerstone of trustworthiness with these pumps is the emphasis on bespoke solutions tailored to specific operational conditions. Comprehensive consultations with expert engineers ensure each pump is fitted with the appropriate impeller design and motor power rating, matching the unique requirements of the client's application. This bespoke approach not only optimizes performance but also prolongs the service life of the equipment, providing better return on investment. In terms of experience, businesses have consistently recorded improvements in productivity and reductions in downtime through the use of high head submersible slurry pumps. The pumps' autonomous operation minimizes the need for manual intervention, thereby reducing labor costs and limiting exposure to potentially hazardous environments. Moreover, the reduced maintenance requirements further contribute to a low total cost of ownership. Lastly, the integration of smart technologies into high head submersible slurry pumps represents a transformative leap forward. Real-time monitoring systems can track performance metrics such as flow rate, pressure, and motor temperature. This facilitates predictive maintenance, allowing operators to anticipate and address wear and potential faults before they lead to significant outages. For industries facing the relentless challenge of managing high-density slurries over considerable distances and heights, high head submersible slurry pumps deliver unparalleled efficiency and reliability. By blending cutting-edge materials, engineering prowess, and intelligent technology, these pumps not only meet but exceed the rigorous demands of modern industrial applications. As a result, they continue to stand out as a critical investment for companies committed to operational excellence and innovation.

A cornerstone of trustworthiness with these pumps is the emphasis on bespoke solutions tailored to specific operational conditions. Comprehensive consultations with expert engineers ensure each pump is fitted with the appropriate impeller design and motor power rating, matching the unique requirements of the client's application. This bespoke approach not only optimizes performance but also prolongs the service life of the equipment, providing better return on investment. In terms of experience, businesses have consistently recorded improvements in productivity and reductions in downtime through the use of high head submersible slurry pumps. The pumps' autonomous operation minimizes the need for manual intervention, thereby reducing labor costs and limiting exposure to potentially hazardous environments. Moreover, the reduced maintenance requirements further contribute to a low total cost of ownership. Lastly, the integration of smart technologies into high head submersible slurry pumps represents a transformative leap forward. Real-time monitoring systems can track performance metrics such as flow rate, pressure, and motor temperature. This facilitates predictive maintenance, allowing operators to anticipate and address wear and potential faults before they lead to significant outages. For industries facing the relentless challenge of managing high-density slurries over considerable distances and heights, high head submersible slurry pumps deliver unparalleled efficiency and reliability. By blending cutting-edge materials, engineering prowess, and intelligent technology, these pumps not only meet but exceed the rigorous demands of modern industrial applications. As a result, they continue to stand out as a critical investment for companies committed to operational excellence and innovation.

Latest news

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Mining Equipment

NewsAug.02,2025