8 сар . 23, 2024 18:09 Back to list

Interchangeable Spare Parts for Slurry Pumps in Various Applications and Industries

Understanding Interchangeable Spare Parts for Slurry Pumps

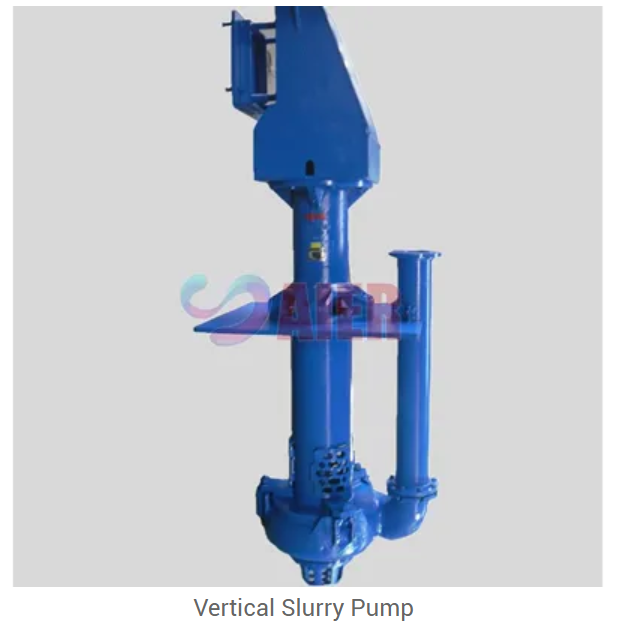

Slurry pumps play a crucial role in various industries, including mining, construction, and wastewater management. Their primary function is to transport abrasive and viscous materials mixed with liquids, often under challenging environmental conditions. Due to the demanding nature of their operation, the need for efficient maintenance and timely replacement of parts becomes paramount. One viable solution to reduce downtime and enhance productivity is the use of interchangeable spare parts for slurry pumps.

Understanding Interchangeable Spare Parts for Slurry Pumps

One of the key advantages of using interchangeable parts is standardization. Many manufacturers design their pumps with a range of compatible components, allowing users to mix and match parts from various models or brands. This interchangeability not only simplifies the replacement process but also enables companies to build a more versatile inventory of spare parts. For instance, if a specific impeller is not available, a similar one from a different model can often fulfill the requirement, maintaining the performance of the pump without delay.

slurry pump interchangeable spare parts

Moreover, interchangeable spare parts can significantly reduce the costs associated with maintenance. By leveraging standard parts, companies can often source replacements at a lower price point than original manufacturer components without compromising on quality. This is particularly beneficial for smaller companies or those operating on tight budgets, as it allows them to maintain efficient operations with limited resources.

In addition to cost savings, using interchangeable parts promotes efficiency in maintenance operations. Technicians can familiarize themselves with fewer types of components, streamlining training processes and reducing the learning curve associated with repairing different models. A technician’s ability to quickly identify and replace faulty parts ensures minimal disruption to overall operations, which is critical in industries where time is money.

However, it is vital to ensure that interchangeable parts are compatible and meet the specific requirements of the pump. Not all components from different brands or models will perform equally, and using substandard parts can lead to operational inefficiencies and increased wear and tear on the pump. Therefore, it is essential to consult with manufacturers or refer to the technical specifications of the components before making a substitution.

In conclusion, the use of interchangeable spare parts in slurry pumps offers numerous benefits, including cost savings, operational efficiency, and easier maintenance processes. As industries continue to evolve, it becomes increasingly important for companies to implement strategies that enhance productivity and minimize downtime. By investing in a standardized inventory of interchangeable parts, businesses can ensure that their slurry pumps remain functional and reliable, ultimately leading to improved performance and profitability.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025