12-р сар . 21, 2024 11:32 Back to list

Optimizing Froth Pump Performance for Increased Efficiency and Reduced Maintenance

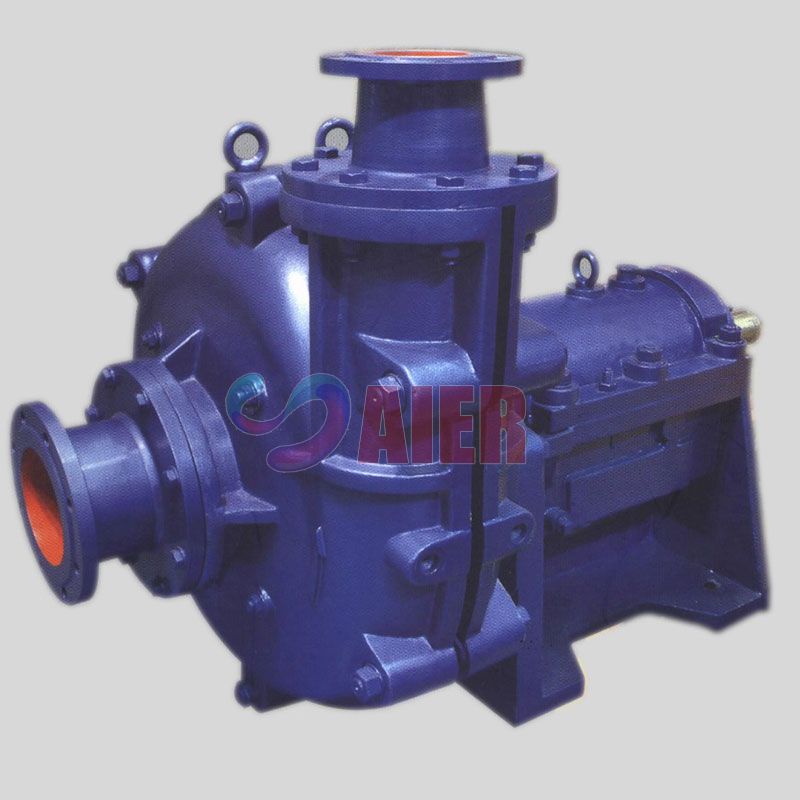

Understanding Froth Pumps An Essential Component in Mineral Processing

Froth pumps play a crucial role in the mineral processing industry, particularly in the flotation process where they transport slurry. This slurry consists of a mixture of water, air, and finely ground minerals. The efficiency and effectiveness of froth pumps directly influence the recovery of valuable minerals, making them vital in operations such as mining, coal processing, and flotation concentration.

The Mechanism of Froth Pumps

Froth pumps are designed specifically to handle frothy slurries, which are typically created in flotation cells. The flotation process involves the addition of chemicals to the slurry, which creates bubbles. These bubbles attach to the desired mineral particles, causing them to float to the surface and form a froth layer. The purpose of the froth pump is to transport this layer efficiently while minimizing the amount of water and non-valuable material that is pulled along.

The construction of a froth pump usually incorporates a unique impeller design that is less susceptible to clogging. It typically features a wider suction inlet, which allows for the free passage of both the mineral-laden froth and any excess water. This design is crucial because traditional pumps may struggle to handle the air within the froth, leading to inefficiencies and potential equipment failure.

Applications of Froth Pumps

Froth pumps are primarily used in a range of industries, including

1. Mining In mining operations, froth pumps are essential for transporting slurry from flotation cells to various processing stages. They help recover valuable minerals such as copper, lead, and zinc efficiently.

2. Coal Processing Froth flotation is a critical process in coal mining where it separates coal from impurities. Froth pumps transport the froth containing coal particles to be further processed.

froth pump

3. Waste Management In some applications, froth pumps can be utilized to manage tailings—waste materials produced after the extraction of minerals. These pumps help in the recovery of any remaining valuable particles while transporting waste materials for disposal.

Advantages of Using Froth Pumps

One of the primary advantages of using froth pumps is their efficiency in handling frothy slurries. The ability to handle high concentrations of suspended solids without losing suction or creating blockages means that mining and processing operations can run continuously, reducing downtime. Furthermore, froth pumps are usually designed to be resistant to wear and tear due to their robust materials, leading to lower maintenance costs over time.

Additionally, froth pumps can influence the overall recovery rates of mineral processing. The proper selection and use of a froth pump can enhance the flotation process, significantly increasing the amount of valuable material recovered. This increase in efficiency can translate directly into improved profitability for mining operations.

Challenges in Froth Pump Usage

Despite their advantages, froth pumps are not without challenges. One common issue is the handling of varying froth densities and compositions. Depending on the type of mineral being processed, the characteristics of the froth can change, impacting pump performance. Operators must continuously monitor and adjust operational parameters to ensure optimal performance.

Another challenge involves the need for routine maintenance. While froth pumps are designed to be robust, regular inspections and maintenance are crucial to prevent any unexpected failures that could lead to costly downtime.

Conclusion

In conclusion, froth pumps are an integral part of the mineral processing landscape, serving as the lifeline that transports valuable materials through flotation processes. Their specialized design allows them to handle the unique challenges presented by frothy slurries, helping to optimize recovery rates and enhance operational efficiency. As the mining and mineral processing industries continue to evolve, advancements in froth pump technology will likely play a crucial role in defining the capabilities and productivity of future operations. Understanding the importance of these pumps and their applications can significantly impact the success of mineral recovery endeavors.

-

High-Quality CH Warman Slurry Pump Factories Heavy Duty & Custom Solutions

NewsMay.28,2025

-

Wholesale Metal-Lined Slurry Pump Parts Durable & Corrosion-Resistant

NewsMay.28,2025

-

High-Efficiency Submerged Mining Vertical Slurry Pump Suppliers

NewsMay.28,2025

-

High-Efficiency & Durable Best Slurry Pumps Reliable Solutions

NewsMay.28,2025

-

China Self Priming Drainage Pump - Durable & High-Capacity Wholesale

NewsMay.28,2025

-

China Tailing Slurry Pump Supplier High-Efficiency & Durable Solutions

NewsMay.28,2025