11-р сар . 21, 2024 23:32 Back to list

ceramic slurry pump factory

Ceramic Slurry Pump Factory Innovations and Applications

In the modern industrial landscape, the demand for durable and efficient pumping solutions has never been higher

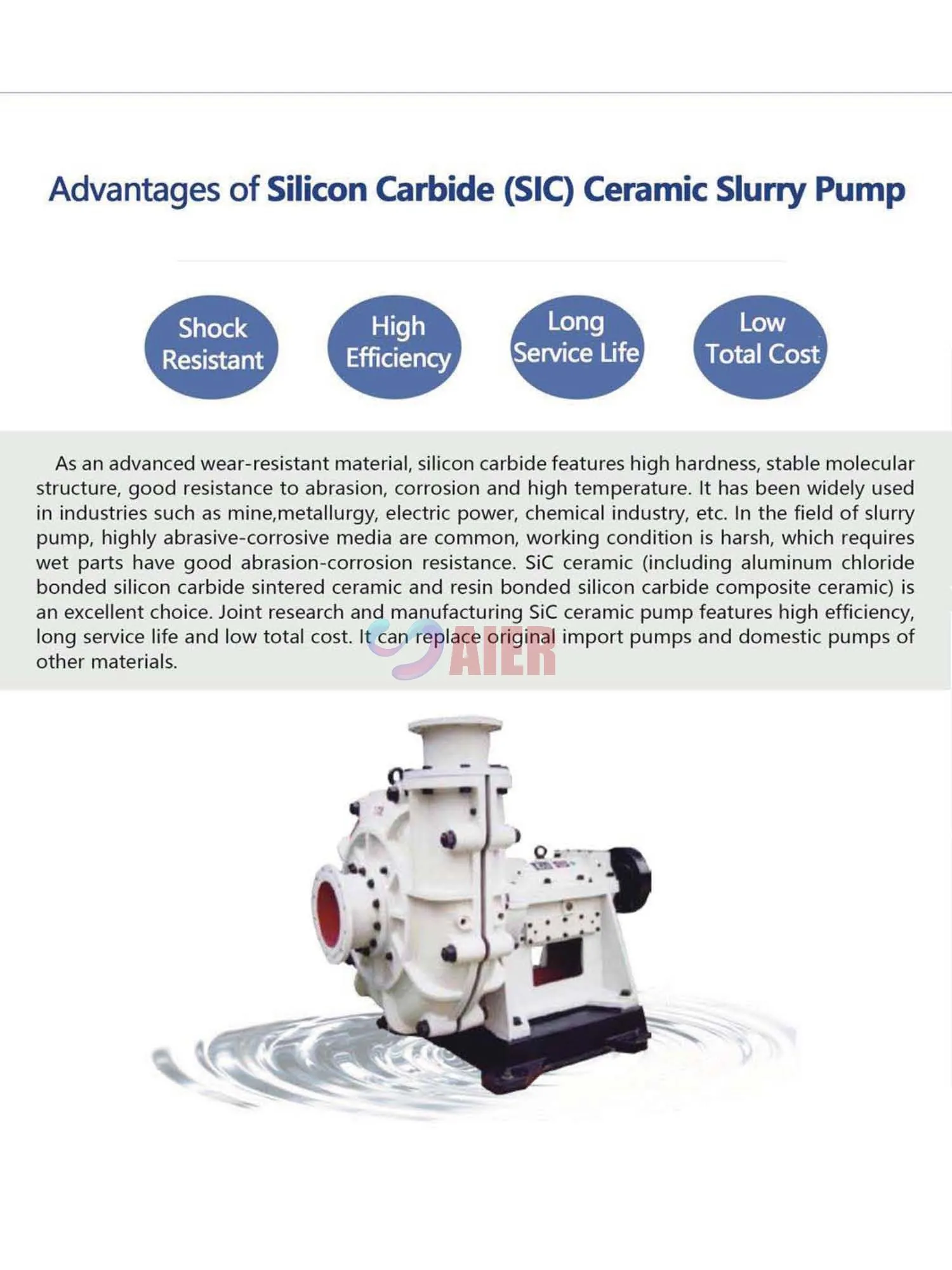

. One of the key players in this field is the ceramic slurry pump factory, which specializes in producing high-performance pumps specifically designed for handling abrasive and corrosive materials.Ceramic slurry pumps are known for their exceptional resistance to wear and tear, making them ideal for industries such as mining, metallurgy, and ceramics. The ceramic materials used in the construction of these pumps provide a significant advantage over traditional metal pumps. They are not only more resistant to corrosion but also capable of operating under extreme temperatures and pressures, ensuring longer service life and reduced maintenance costs.

At a ceramic slurry pump factory, the manufacturing process involves advanced technologies and skilled craftsmanship. The production begins with the careful selection of raw materials, including high-purity ceramic compounds that can withstand harsh environments. These materials undergo rigorous testing to ensure they meet industry standards for quality and performance.

ceramic slurry pump factory

The design phase is crucial in developing a pump that can efficiently handle various types of slurries, which often contain solid particles suspended in a liquid. Engineers work to optimize the pump’s geometry, impeller design, and casing integrity to enhance flow rates and minimize energy consumption. Moreover, the factory utilizes computer-aided design (CAD) software to simulate pump performance under different operating conditions, allowing for precision engineering.

Once the design is finalized, the manufacturing process includes high-tech methods such as precision casting and machining. After assembly, each pump undergoes a strict quality assurance process, ensuring it meets the necessary specifications before leaving the factory. This commitment to quality ensures that clients receive pumps that perform reliably in challenging operational circumstances.

The applications of ceramic slurry pumps are diverse. In the mining industry, they are essential for transporting mineral slurry from extraction sites to processing facilities. In the ceramics industry, they help in the mixing and transfer of raw materials, ensuring consistency in product quality. Additionally, their use in wastewater treatment facilities reflects their versatility and capability in handling various slurry types.

In conclusion, a ceramic slurry pump factory plays a vital role in the supply chain of numerous industries that depend on the efficient movement of abrasive and corrosive materials. With ongoing innovations and a commitment to quality, these factories are well-positioned to meet the evolving demands of the global market, setting the standard for reliability and performance in pumping solutions.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025