10 сар . 31, 2024 12:59 Back to list

Ceramic Slurry Pump Manufacturing Facilities and Their Key Advantages in Industry

The Rise of Ceramic Slurry Pump Factories

In recent years, the demand for specialized pumping solutions has grown exponentially, particularly in industries that handle abrasive materials. This surge has given rise to the establishment of ceramic slurry pump factories, which manufacture pumps designed to efficiently transport slurry—a mixture of solids and liquids—while minimizing wear and tear. These factories play a crucial role in various sectors, including mining, construction, and wastewater treatment.

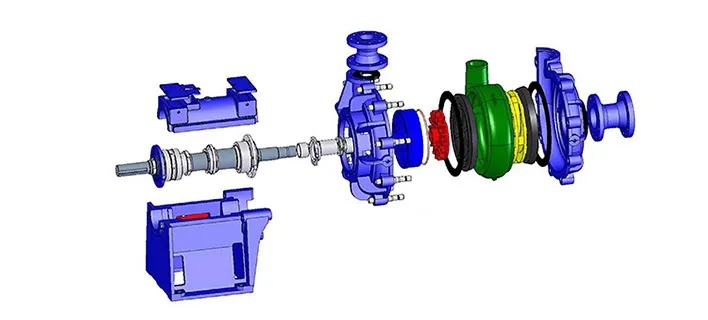

Ceramic slurry pumps are engineered with advanced materials that exhibit superior resistance to abrasion, corrosion, and extreme temperatures. The ceramic components not only enhance durability but also ensure that the pumps maintain operational efficiency over extended periods. This is particularly important in industries where downtime can lead to significant financial losses. As a result, ceramic slurry pumps have become the preferred choice for operators looking to achieve both longevity and reliability in their pumping systems.

The establishment of ceramic slurry pump factories involves substantial investment in technology and expertise

. Manufacturers are continuously innovating to develop new designs that can handle more challenging applications. State-of-the-art production techniques, such as precision casting and 3D printing, are increasingly being employed to create components that meet the specific needs of different industries. Additionally, these factories often collaborate closely with engineers and operators to tailor pumps for particular operational conditions.ceramic slurry pump factories

One notable aspect of ceramic slurry pump factories is their commitment to sustainability. By developing pumps that can significantly reduce energy consumption and improve efficiency, these manufacturers contribute to environmentally friendly practices. This focus on sustainability not only aligns with global initiatives to reduce carbon footprints but also appeals to a growing base of environmentally conscious consumers.

Market competition among ceramic slurry pump manufacturers is intensifying, with both established players and new entrants vying for market share. This dynamic competition fosters innovation and drives down costs, ultimately benefiting end-users who can access high-quality products at more competitive prices. Furthermore, as global supply chains become more interconnected, these factories are poised to expand their reach, catering to clients in diverse geographical locations.

In conclusion, ceramic slurry pump factories embody the intersection of technology, industry needs, and environmental responsibility. Their ability to produce robust, efficient, and sustainable pumping solutions positions them as key players in sectors that rely heavily on handling slurries. As the demand for these pumps continues to grow, manufacturers are likely to further innovate and expand their offerings, ensuring they meet the ever-evolving challenges faced by their clients. The future of ceramic slurry pump factories looks promising, underpinned by a strong focus on quality, efficiency, and sustainability that will serve industries well for years to come.

-

Top Submersible Pump Companies High Quality Manufacturers & Suppliers in China

NewsJul.08,2025

-

High Quality Seal for 5 Inch Dredge Pump Reliable China Manufacturer & Supplier

NewsJul.08,2025

-

High-Efficiency Slurry Sand Pump from Leading China Manufacturer – Durable & Reliable Solutions

NewsJul.07,2025

-

High-Quality Slurry Pump Made in China Durable Steel Mill Slurry Pump & Parts

NewsJul.07,2025

-

High Quality Excavator Dredge Pump Manufacturer & Suppliers from China – Reliable, Durable, Efficient Solutions

NewsJul.07,2025

-

Wholesale Slurry Pump Closed Impeller Supplier High Efficiency China Slurry Pump Closed Impeller

NewsJul.06,2025