ഫെബ്രു . 13, 2025 13:26 Back to list

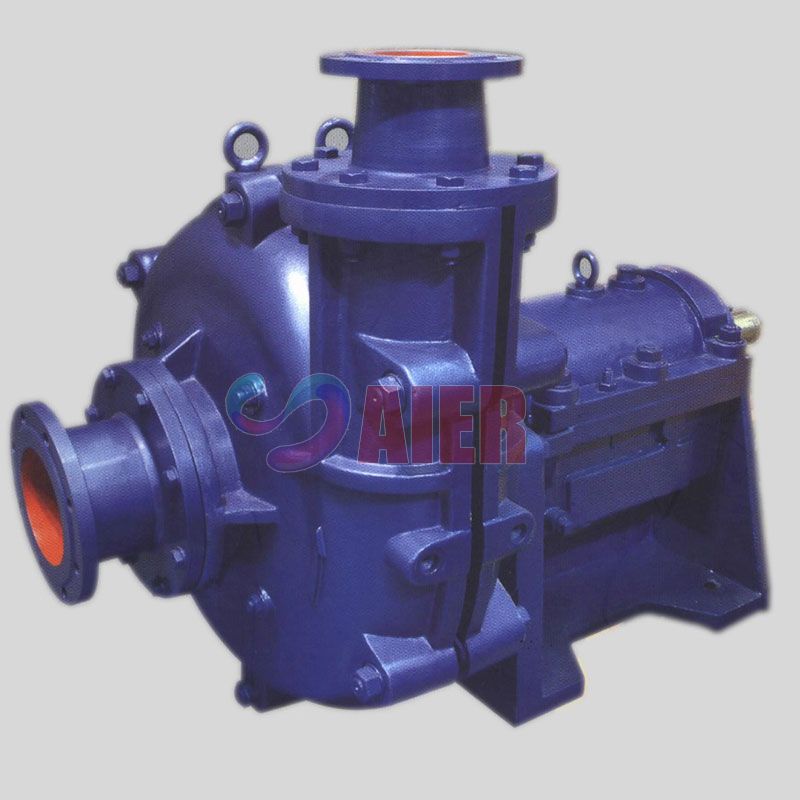

wholesale slurry pump spare parts rubber parts

Slurry pump parts, especially the impeller, play a critical role in the efficiency and durability of pump systems used in handling abrasive and corrosive slurries. When it comes to selecting the right pump parts, especially the rubber impeller, experience, expertise, authoritativeness, and trustworthiness are paramount factors.

Analyzing case studies and real-world applications further verifies the authority of rubber impellers in the slurry pumping industry. Large-scale mining operations and industrial plants report significant reductions in maintenance downtime and component replacement costs when switching from metal to rubber impellers. This reduction is attributable to the material's inherent resistance to chipping and corrosion, aligning with the operational demands of heavy-duty and high-volume slurry handling. From the perspective of an authoritativeness standard, manufacturers who focus on high-quality rubber impellers undergo rigorous testing and certifications. These processes often include simulated wear cycles and chemical exposure tests, certifying that the rubber materials can endure the specific challenges presented by different types of slurries. When selecting a supplier, verifying these certifications and understanding the R&D behind their material selection can provide a measure of confidence in their product's efficacy and durability. Trustworthiness comes from transparency in performance data and customer service. Leading manufacturers provide comprehensive warranties and detailed product specifications, ensuring that customers have verifiable data to back their purchase decisions. User reviews and testimonials from clients who have successfully integrated rubber impellers into their systems can further build trust. Any company considering a switch to rubber impeller components would benefit significantly from engaging in consultations with specialists who can provide tailored advice, ensuring that the correct impeller type and configuration is chosen based on their specific slurry composition and operational parameters. Ultimately, the choice of a slurry pump part like an impeller should reflect a balance between upfront costs and the long-term benefits of reduced maintenance and greater reliability. Experience-based insights, combined with technological advancements in rubber material formulations, position rubber impellers as a practical, efficient solution for many challenging slurry pump applications. Those who prioritize performance longevity and adaptability should consider the advantages that rubber impellers bring to the fore. With the right expertise and informed decision-making, companies can ensure their slurry pump systems operate at peak efficiency, reducing operational challenges and encouraging economic benefits in the long run.

Analyzing case studies and real-world applications further verifies the authority of rubber impellers in the slurry pumping industry. Large-scale mining operations and industrial plants report significant reductions in maintenance downtime and component replacement costs when switching from metal to rubber impellers. This reduction is attributable to the material's inherent resistance to chipping and corrosion, aligning with the operational demands of heavy-duty and high-volume slurry handling. From the perspective of an authoritativeness standard, manufacturers who focus on high-quality rubber impellers undergo rigorous testing and certifications. These processes often include simulated wear cycles and chemical exposure tests, certifying that the rubber materials can endure the specific challenges presented by different types of slurries. When selecting a supplier, verifying these certifications and understanding the R&D behind their material selection can provide a measure of confidence in their product's efficacy and durability. Trustworthiness comes from transparency in performance data and customer service. Leading manufacturers provide comprehensive warranties and detailed product specifications, ensuring that customers have verifiable data to back their purchase decisions. User reviews and testimonials from clients who have successfully integrated rubber impellers into their systems can further build trust. Any company considering a switch to rubber impeller components would benefit significantly from engaging in consultations with specialists who can provide tailored advice, ensuring that the correct impeller type and configuration is chosen based on their specific slurry composition and operational parameters. Ultimately, the choice of a slurry pump part like an impeller should reflect a balance between upfront costs and the long-term benefits of reduced maintenance and greater reliability. Experience-based insights, combined with technological advancements in rubber material formulations, position rubber impellers as a practical, efficient solution for many challenging slurry pump applications. Those who prioritize performance longevity and adaptability should consider the advantages that rubber impellers bring to the fore. With the right expertise and informed decision-making, companies can ensure their slurry pump systems operate at peak efficiency, reducing operational challenges and encouraging economic benefits in the long run.

Latest news

-

Reliable Submersible Well Pump Manufacturer – Quality & Durability

NewsJul.26,2025

-

Submersible Pump Shaft Manufacturer - High Quality Vertical and Ceramic Slurry Pumps

NewsJul.25,2025

-

Top Submersible Well Pump Manufacturer - Reliable & Durable Solutions

NewsJul.24,2025

-

Leading Submersible Well Pump Manufacturer – Reliable & Durable Pumps

NewsJul.23,2025

-

Submersible Well Pump Manufacturer: Reliable & Efficient Solutions

NewsJul.22,2025

-

China Slurry Pump Volute Liner Factory | Durable Spare Parts

NewsJul.21,2025