സെപ് . 30, 2024 18:32 Back to list

China Rubber Throat Bush for Slurry Pumps - Durable and Reliable Solutions

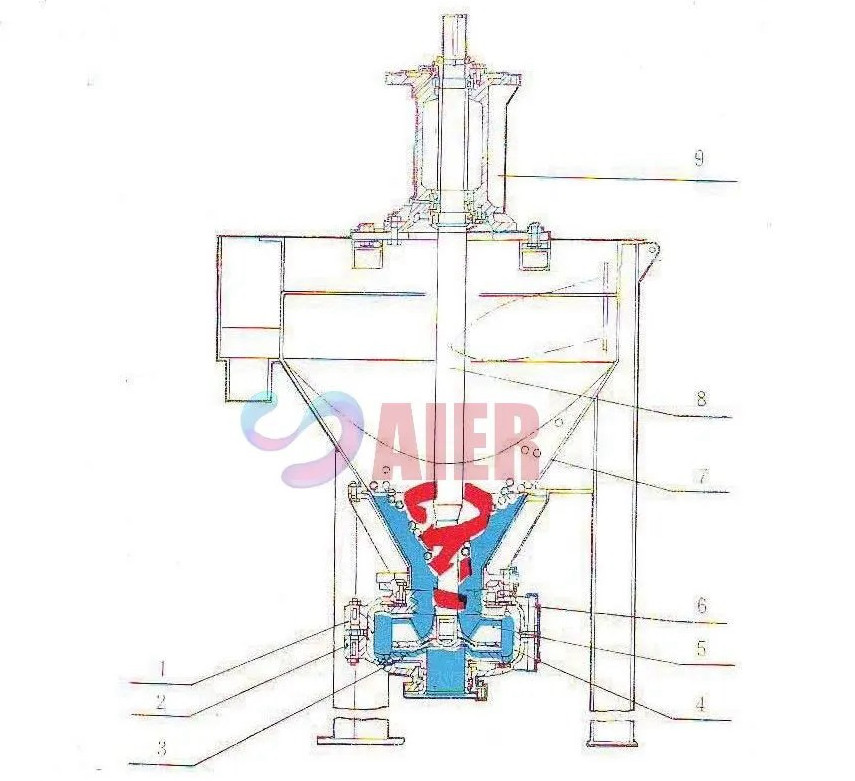

Understanding China’s Slurry Pump Rubber Throat Bush

In the mining, dredging, and mineral processing industries, slurry pumps play a vital role in transporting mixtures of liquids and solids. Among the essential components of these pumps is the rubber throat bush, a part that significantly influences the performance and longevity of the equipment. This article delves into the role of slurry pump rubber throat bushes, highlighting their design, manufacturing processes in China, and their impact on operational efficiency.

The Role of Rubber Throat Bushes in Slurry Pumps

The rubber throat bush serves as a vital interface in slurry pumps. It is designed to manage the flow of slurry and reduce the wear and tear of the pump components. The primary function of the throat bush is to maintain the optimal alignment and minimize the clearance between the impeller and the wearing surface. This precise fit is crucial for preventing excessive leakage, which can lead to reduced pumping efficiency and increased operational costs.

Moreover, the rubber material provides several advantages over metal alternatives, such as resistance to corrosion, erosion, and chemical attack. This durability makes rubber throat bushes an excellent choice for handling abrasive slurries often found in mining and mineral processing applications.

Manufacturing Excellence in China

China has emerged as a global leader in the production of industrial pumps and their components, including rubber throat bushes. The country boasts a vast array of manufacturers equipped with advanced technologies and skilled labor. The manufacturing process typically involves several steps that ensure the quality and reliability of the final product.

1. Material Selection High-quality rubber compounds are chosen based on their physical and chemical properties. The selection process often includes evaluating hardness, flexibility, and resistance to wear and tear. By using advanced synthetic rubbers, manufacturers can enhance the performance characteristics of throat bushes.

2. Molding Process The selected rubber materials are then subjected to a molding process, usually using techniques like compression molding or injection molding. This allows for precise shaping and dimensional accuracy, essential for achieving a perfect fit within the slurry pump.

3. Curing Post-molding, the rubber components undergo a curing process, often involving heat and pressure. This step cross-links the rubber molecules, enhancing strength and elasticity, which are critical for the operational demands of slurry pumping.

china slurry pump rubber throat bush

4. Quality Control Rigorous quality control measures are implemented at various stages of production. Manufacturers perform checks for dimensional accuracy, hardness, and resistance to wear. Additionally, some companies employ advanced testing methods such as pressure testing to ensure reliability under operational conditions.

5. Customization Many manufacturers in China offer customization options for rubber throat bushes to cater to specific industry needs. This capability allows clients to specify dimensions, rubber formulations, and features tailored to their unique applications.

Impact on Operational Efficiency

The quality of the rubber throat bush directly affects the overall performance of the slurry pump. A well-designed and manufactured throat bush can lead to

- Increased Efficiency By minimizing leakage and maintaining optimal flow, high-quality throat bushes significantly enhance the pumping efficiency.

- Reduced Maintenance Costs Durable rubber materials reduce wear and tear on the pump’s impeller and casing, leading to lower maintenance frequency and costs.

- Extended Service Life Rubber throat bushes that resist corrosion and abrasion can dramatically extend the service life of slurry pumps, providing a better return on investment.

- Operational Reliability By using reliable components, operators can achieve more consistent performance, which is critical in applications where downtime can result in substantial financial losses.

Conclusion

In summary, the rubber throat bush is a critical component of slurry pumps, significantly impacting operation and efficiency. With a strong manufacturing base, China continues to produce high-quality rubber throat bushes that meet the demanding requirements of the industry. Investing in reliable slurry pump components is essential for enhancing operational efficiency and achieving sustainable success in the harsh environments typical of mining and mineral processing industries. As global demand for such components grows, understanding their importance will be key for organizations looking to stay competitive and efficient.

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025