Дек . 14, 2024 14:12 Back to list

Vertical Centrifugal Slurry Pump Manufacturing Facility Overview and Capabilities

Vertical Centrifugal Slurry Pump An Overview of Manufacturing and Applications

In various industrial sectors, the reliable transportation of abrasive and corrosive materials is critical. The vertical centrifugal slurry pump stands out as an essential piece of equipment designed to handle these challenging tasks effectively. This article delves into the manufacturing processes, applications, and advantages of vertical centrifugal slurry pumps, particularly focusing on the factors that make them a staple in numerous industries.

Understanding Vertical Centrifugal Slurry Pumps

Vertical centrifugal slurry pumps are engineered to manage the movement of slurry—mixture of liquid with solid particles—under challenging conditions. Their design allows them to function in heavy-duty environments where other pumps may fail. These pumps utilize a vertical orientation, which helps in reducing the footprint of the equipment, making them suitable for plants with limited space.

Manufacturing Process

The manufacturing of vertical centrifugal slurry pumps involves several key stages, each critical to ensuring the equipment's durability and efficiency. The process typically begins with the selection of high-quality materials such as cast iron, stainless steel, or specialized alloys, which can withstand wear and corrosion.

1. Casting and Machining The selected materials undergo a casting process that shapes the components of the pump. This is followed by precision machining to create the necessary tolerances and surface finishes crucial for optimal performance.

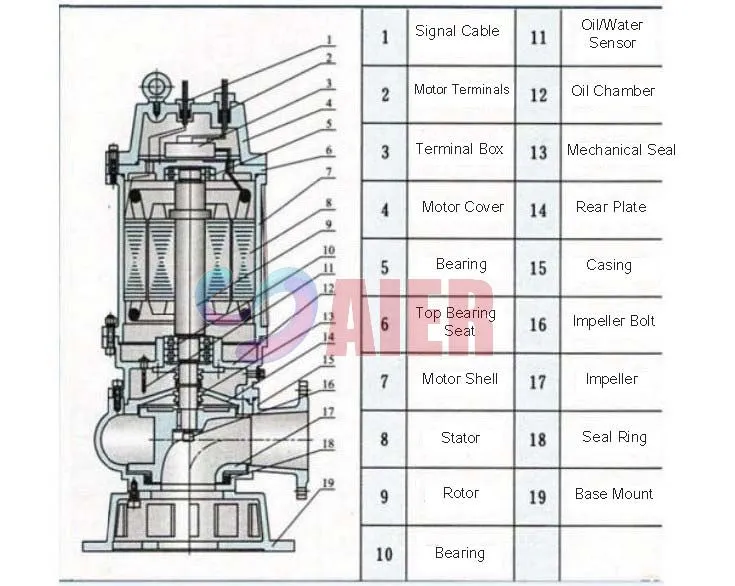

2. Assembly Once the components are fabricated, they are assembled with great attention to detail. The impeller, volute casing, and other internals are aligned carefully to prevent vibration and ensure efficient fluid flow.

3. Testing After assembly, pumps undergo rigorous testing including hydraulic testing to evaluate the performance under various conditions. This ensures that each pump meets the required specifications and standards before being shipped to customers.

vertical centrifugal slurry pump factory

4. Quality Control Quality assurance is a fundamental aspect of manufacturing. It involves checking for defects and ensuring that each pump functions correctly. This step is vital, considering that the pumps are often used in demanding environments.

Applications

Vertical centrifugal slurry pumps find widespread use across numerous industries. They are commonly employed in mining, mineral processing, and waste water treatment facilities where the transportation of slurries containing abrasive particles is necessary. In the mining sector, these pumps are instrumental in the processes of quarrying and mineral extraction, ensuring efficient slurry communication between different stages of production.

Additionally, they are essential in the construction industry for transferring materials such as concrete slurries and can be utilized in the chemical sector for moving corrosive substances.

Advantages of Vertical Centrifugal Slurry Pumps

One of the standout advantages of vertical centrifugal slurry pumps is their ability to handle high solid concentrations without clogging. Their vertical orientation not only saves space but also minimizes the risk of cavitation, a common issue in conventional horizontal pumps.

Moreover, these pumps are designed for ease of maintenance. Many models allow for easy access to internal components, which facilitates streamlined servicing and reduces downtime. Additionally, because they frequently feature a wet end design that is optimized for slurry handling, they can deliver high efficiency, reducing overall operational costs.

Conclusion

In conclusion, vertical centrifugal slurry pumps represent a crucial element in many industrial processes, providing a robust solution for the transportation of abrasive and corrosive materials. With a comprehensive manufacturing process that emphasizes quality and efficiency, these pumps cater to a range of applications across different sectors. As industries continue to evolve, the demand for reliable slurry handling solutions like vertical centrifugal pumps is bound to grow, making them indispensable tools in modern manufacturing and production environments.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025