Окт . 13, 2024 14:14 Back to list

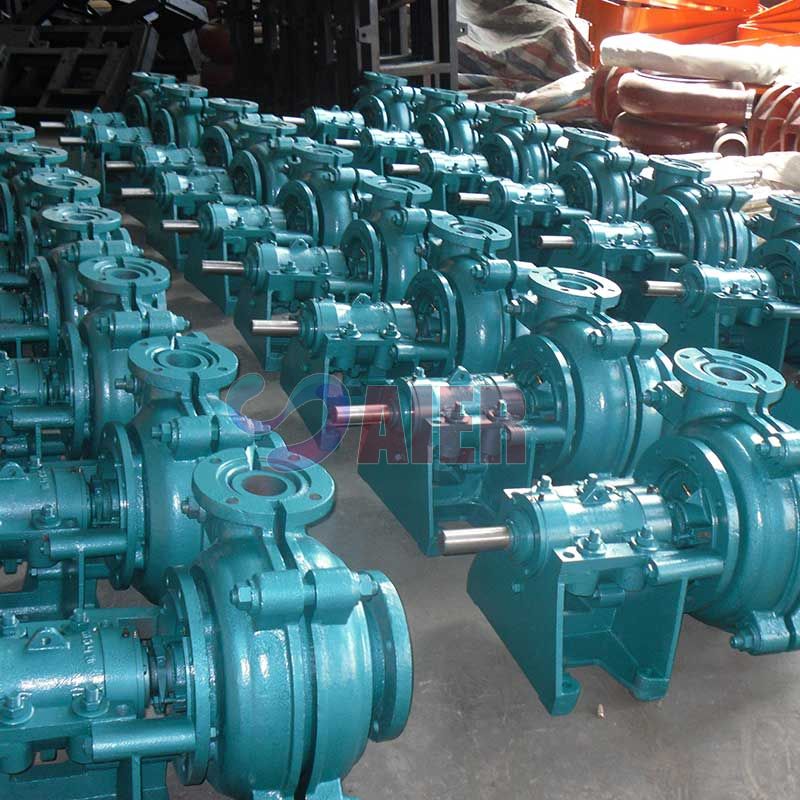

Durable and Efficient Slurry Pump Casing for Optimal Performance and Longevity

High-Quality Slurry Pump Casing An Essential Component for Efficient Performance

The importance of reliable and efficient pumping systems cannot be overstated, especially in industries dealing with abrasive and corrosive materials. Slurry pumps, designed to handle thick mixtures of liquid and solids, play a crucial role in mining, mineral processing, and wastewater treatment. At the heart of these pumps lies the casing, a vital component that significantly influences the performance and durability of the entire pumping system. This article will delve into the significance of high-quality slurry pump casing, exploring its materials, design, and the benefits of investing in superior quality.

Understanding Slurry Pump Casings

A slurry pump casing serves as the outer shell of the pump, housing the impeller and other critical components. Its primary function is to contain the slurry as it passes through, ensuring efficient transfer while protecting the internal parts from wear and damage. The design of the casing needs to be robust enough to withstand the abrasive nature of slurry, which can consist of sand, gravel, minerals, and other particulates.

Materials Used in Slurry Pump Casings

The selection of materials for slurry pump casings is paramount to their performance and longevity. High-quality casings are commonly made from various alloys and hard materials, tailored to resist corrosion and wear. Cast iron and stainless steel are popular choices due to their durability, while specialized alloys like high-chrome and rubber-lined designs are favored for their ability to handle abrasive materials.

Rubber-lined casings provide an extra layer of protection against wear, particularly in applications involving highly abrasive slurries. The inner lining absorbs the impact from solids, extending the life of the casing and reducing maintenance costs. Additionally, the choice of material can influence the pump's efficiency, as smoother surfaces facilitate better flow dynamics, reducing energy consumption and operational costs.

Design Considerations

high quality slurry pump casing

The design of slurry pump casings is equally critical, dictating the pump's performance, efficiency, and maintenance requirements. An optimally designed casing features a smooth flow path that minimizes turbulence, ensuring that the slurry moves uniformly through the pump.

Moreover, advanced design technologies, such as computational fluid dynamics (CFD), can be employed to simulate various flow scenarios and optimize casing shapes for specific applications. This level of engineering ensures that the pump performs efficiently under different operating conditions, enhancing reliability and reducing downtime.

Benefits of High-Quality Casing

Investing in high-quality slurry pump casings offers numerous advantages. First and foremost, a robust casing significantly reduces wear and tear on the pump components, leading to lower maintenance costs and extended operational lifespans. Operators can expect fewer shutdowns for repairs or replacements, resulting in enhanced productivity.

Additionally, high-quality casings can improve pumping efficiency. With optimal designs and materials, these casings reduce energy consumption and improve flow rates, benefiting both the environment and the bottom line. For industries where energy costs represent a significant portion of operational expenses, even a slight improvement in pump efficiency can yield substantial financial savings over time.

Conclusion

In conclusion, the casing of a slurry pump is more than just a protective shell; it is a crucial element that directly impacts performance, efficiency, and longevity. By opting for high-quality materials and advanced designs, industries can ensure their pumping systems operate at peak performance, even in the most challenging conditions. As the demand for efficient and reliable slurry handling continues to grow, the focus on high-quality slurry pump casings will remain a priority for those looking to optimize their operations and maintain competitive advantages in their respective fields. With the right investment in quality casing, businesses can achieve greater reliability, lower costs, and improved overall performance in their slurry pump systems.

-

High Quality Warman Slurry Pump Drawings Supplier & Factory Reliable Customization

NewsJul.06,2025

-

China SP Slurry Pump Supplier – Vertical Sump Pump Rubber Lined Manufacturer & Factory

NewsJul.05,2025

-

High Quality Submersible Slurry Pump with Agitator Manufacturer & Factory Reliable Submersible Pump Solutions

NewsJul.05,2025

-

Cheap Dredge Pump for Sale – China Cheap Submersible Pump for Wastewater Supplier

NewsJul.05,2025

-

Wholesale Casting Dredge Pump Part - High Quality China Manufacturers & Suppliers

NewsJul.04,2025

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025