Ное . 07, 2024 08:23 Back to list

Durable and Efficient Casting Parts for High-Performance Dredge Pumps

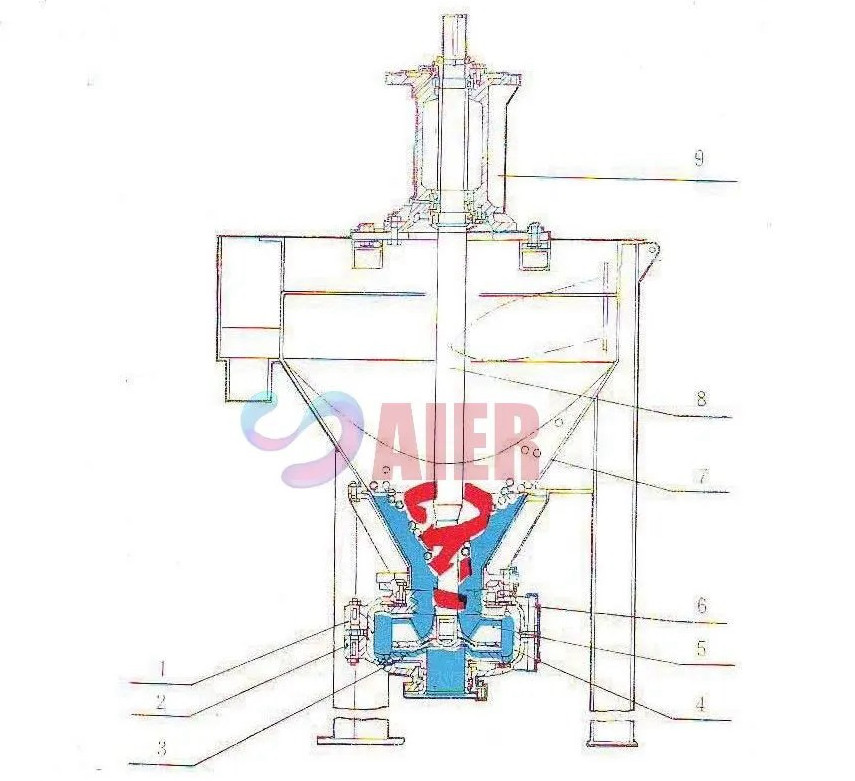

High-Quality Casting Dredge Pump Parts Essential Components for Efficient Dredging Operations

Dredging is a crucial activity in various industries, including construction, mining, and environmental management. It involves removing sediment and debris from the bottom of water bodies, which facilitates navigation, maintains water quality, and supports the development of infrastructure. Central to the efficiency of dredging operations are dredge pumps, which play a vital role in transporting the removed material. One of the key factors that determine the performance and longevity of these pumps is the quality of their components, particularly the casting parts.

Understanding Dredge Pumps and Their Functions

Dredge pumps are specialized pumps designed to handle abrasive materials such as mud, sand, and gravel. They are typically robust and capable of operating in harsh environments, making them indispensable in dredging projects. The primary function of a dredge pump is to draw up slurry from the dredging site and transfer it to a designated location, whether it be a barge, truck, or disposal area.

The effectiveness of a dredge pump is heavily influenced by its parts, most notably those made through casting processes. High-quality casting dredge pump parts ensure that the pumps operate efficiently and have a longer service life, which ultimately leads to lower operational costs and increased productivity.

The Importance of High-Quality Casting

Casting is a manufacturing process where liquid material is poured into a mold to create a specific shape as it cools and solidifies. This technique is widely used in producing components for dredge pumps due to its ability to create complex shapes and fine details while maintaining structural integrity. The following points highlight the importance of using high-quality casting in manufacturing dredge pump parts

1. Durability Dredge pumps are often subjected to extreme operating conditions, including high pressures and abrasive materials. High-quality casting materials, such as ductile iron or high-chrome alloys, ensure that the parts can withstand wear and tear over time, significantly reducing the likelihood of failure.

high quality casting dredge pump part

2. Precision The efficiency of a dredge pump relies on the precise fitting of its components. High-quality casting processes yield parts with tight tolerances, minimizing the potential for leaks and ensuring smooth operation.

3. Corrosion Resistance Many dredging environments expose pumps to corrosive substances, including saltwater and various chemicals. Utilizing high-quality casting materials that include corrosion-resistant properties extends the lifespan of the components and enhances their performance.

4. Cost-Effectiveness While high-quality casting parts may come with a higher initial price, the long-term benefits far outweigh these costs. Fewer replacements and repairs lead to reduced downtime and maintenance expenses, contributing to a better return on investment.

Choosing the Right Supplier

Selecting the right supplier for high-quality casting dredge pump parts is crucial for the success of any dredging project. Companies should look for suppliers that adhere to stringent quality control standards and possess a proven track record in manufacturing durable pump components. Certifications such as ISO 9001 can be indicators of a supplier's commitment to maintaining high-quality production processes.

Furthermore, it’s beneficial to choose suppliers that offer customization options. Not all dredging projects are the same; therefore, having the flexibility to tailor parts to specific operational requirements can lead to enhanced performance and efficiency.

Conclusion

High-quality casting dredge pump parts are more than mere components; they are the backbone of effective and efficient dredging operations. By understanding the critical role these parts play, companies can make informed decisions about their use and procurement. Investing in top-grade casting parts not only improves the operational performance of dredge pumps but also ensures longer service life and reduced total cost of ownership. As the demand for efficient and reliable dredging solutions continues to rise, the focus on high-quality casting will remain a key factor in the industry’s evolution.

-

High Quality Slurry Pump Seals Reliable China Suppliers & Manufacturers

NewsJun.24,2025

-

High Quality Portable Submersible Slurry Pump Supplier & Manufacturer from China

NewsJun.10,2025

-

Slurry Pump Parts Manufacturer – High Quality Rubber Spare Parts from China

NewsJun.10,2025

-

High Quality 1/3 HP Submersible Sump Pump with Vertical - Reliable Supplier & Factory Price

NewsJun.10,2025

-

High-Efficiency Centrifugal Slurry Pumps India

NewsJun.10,2025

-

High Quality Warman Centrifugal Slurry Pump Suppliers & Factory

NewsJun.10,2025