Јан . 13, 2025 15:07 Back to list

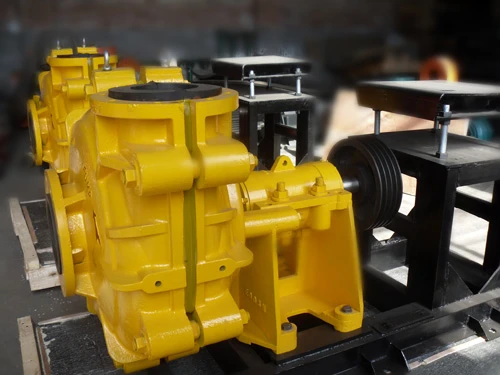

high pressure slurry pump

High Pressure Slurry Pumps Navigating the World of Superior Fluid Handling

Given the technical complexities and rigorous performance requirements, it is advisable to work with experienced suppliers who boast a track record of authority in the field. Such expertise ensures the pumps are properly matched to the application, considering factors like solid content, slurry abrasiveness, and fluid pH levels. Consulting with experts can also aid in figuring out whether a single-stage or multi-stage pump design will best meet the operational demands. Equally important is regular pump maintenance, which underscores the trustworthiness of the operation. Implementing a proactive maintenance schedule not only enhances the lifespan of the pump but also prevents unexpected failures. Routine inspections and part replacements guided by manufacturer-recommended schedules are best practices that help maintain maximum efficiency and reliability. For companies pushing the limits of processing and transporting complex slurry combinations, investing in training and certification programs for their staff elevates the operational hiccup into streamlined processes. These initiatives ensure personnel are up-to-date with the latest advancements in pump technology and maintenance techniques, providing added value by improving safety protocols and reducing environmental impact due to potential leakages or spillages. Trust in high pressure slurry pump solutions derives from the innovation and reliability they offer. As technological advancements continue to enhance pump capabilities, industry standards evolve, presenting fresh opportunities to optimize performance and reduce operational costs. By committing to excellence in pump selection, maintenance, and training, businesses solidify their standing as leaders in this crucial aspect of industrial operations, ensuring not only short-term productivity but long-term sustainability.

Given the technical complexities and rigorous performance requirements, it is advisable to work with experienced suppliers who boast a track record of authority in the field. Such expertise ensures the pumps are properly matched to the application, considering factors like solid content, slurry abrasiveness, and fluid pH levels. Consulting with experts can also aid in figuring out whether a single-stage or multi-stage pump design will best meet the operational demands. Equally important is regular pump maintenance, which underscores the trustworthiness of the operation. Implementing a proactive maintenance schedule not only enhances the lifespan of the pump but also prevents unexpected failures. Routine inspections and part replacements guided by manufacturer-recommended schedules are best practices that help maintain maximum efficiency and reliability. For companies pushing the limits of processing and transporting complex slurry combinations, investing in training and certification programs for their staff elevates the operational hiccup into streamlined processes. These initiatives ensure personnel are up-to-date with the latest advancements in pump technology and maintenance techniques, providing added value by improving safety protocols and reducing environmental impact due to potential leakages or spillages. Trust in high pressure slurry pump solutions derives from the innovation and reliability they offer. As technological advancements continue to enhance pump capabilities, industry standards evolve, presenting fresh opportunities to optimize performance and reduce operational costs. By committing to excellence in pump selection, maintenance, and training, businesses solidify their standing as leaders in this crucial aspect of industrial operations, ensuring not only short-term productivity but long-term sustainability.

Latest news

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Gold Mining Equipment, Sand Dredging Machines

NewsAug.03,2025

-

Small Dredger & Marine Pontoon-Aier Machinery Hebei Co., Ltd|Industrial Equipment&Mining Machinery

NewsAug.03,2025

-

Small Dredger & Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Gold Mining Equipment, Industrial Dredging

NewsAug.03,2025

-

Warman Slurry Pump Bearing Assembly - Durable & Efficient

NewsAug.03,2025

-

Small Dredger and Marine Pontoon Solutions-Aier Machinery Hebei Co., Ltd|Marine Dredge Pump, Small Slurry Pump

NewsAug.02,2025

-

Small Dredger and Marine Pontoon - Aier Machinery Hebei Co., Ltd | Industrial Mining Equipment

NewsAug.02,2025